Semiconductor device and manufacturing method thereof, and electronic device

A manufacturing method and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as uneven thickness of tunneling oxide layers, achieve good breakdown voltage, and improve device coupling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

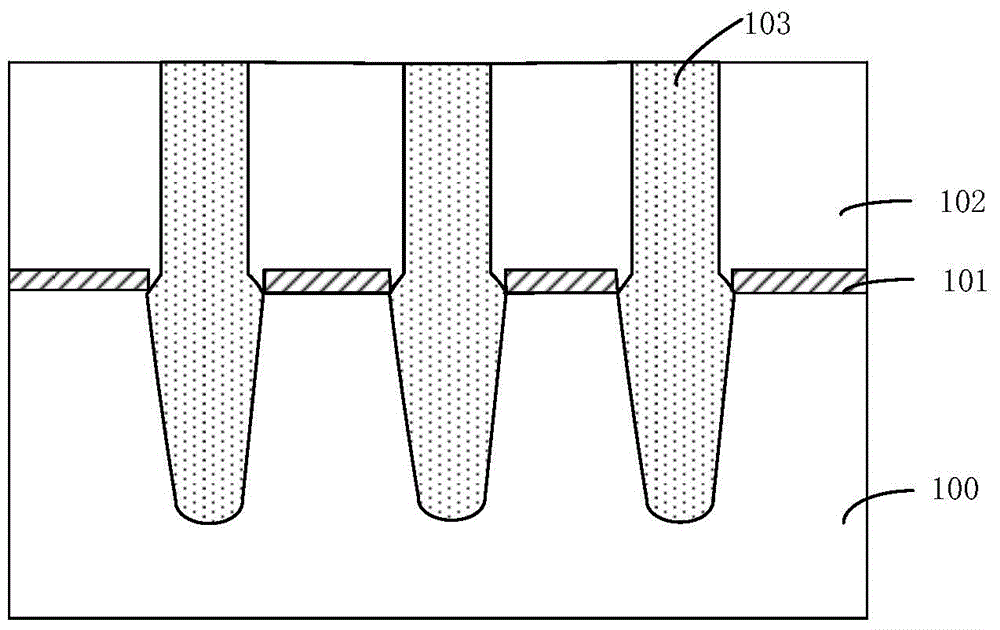

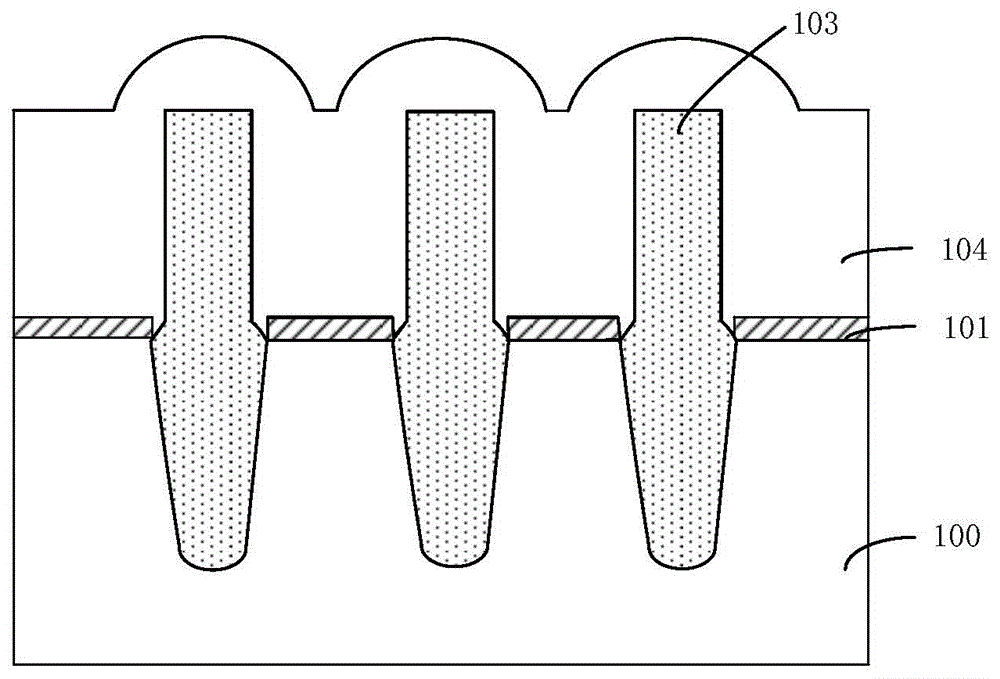

[0039] The following will combine Figures 2A-2G Describe in detail the manufacturing method of the embedded flash memory of the present invention, Figures 2A-2G It is a cross-sectional view of the structure of the memory in the process of fabricating the embedded flash memory according to an embodiment of the present invention.

[0040] Such as Figure 2A As shown, a semiconductor substrate 200 is provided in which a well is formed.

[0041]The semiconductor substrate may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S-SiGeOI), silicon-on-insulator Silicon germanium (SiGeOI) and germanium on insulator (GeOI), etc. As an example, in this embodiment, single crystal silicon is selected as the constituent material of the semiconductor substrate.

[0042] The semiconductor substrate 200 includes three regions, namely: a first region for forming a logic circuit gate structure,...

Embodiment 2

[0084] According to the manufacturing method of the present invention, a semiconductor device is also provided, and the semiconductor device includes a floating gate with a T-shaped structure.

[0085] Exemplarily, the bottom width of the floating gate is 50 nm to 75 nm, and the top width of the floating gate is 60 nm to 110 nm.

Embodiment 3

[0087] An embodiment of the present invention provides an electronic device, which includes a semiconductor device. Wherein, the semiconductor device is the semiconductor device described in Embodiment 2, or the semiconductor device manufactured according to the method for manufacturing a semiconductor device described in Embodiment 1.

[0088] The electronic device of this embodiment can be any electronic product or equipment such as mobile phone, tablet computer, notebook computer, netbook, game console, TV set, VCD, DVD, navigator, camera, video recorder, voice recorder, MP3, MP4, PSP, etc. , can also be any intermediate product including semiconductor devices. The electronic device according to the embodiment of the present invention has better performance due to the use of the above-mentioned semiconductor device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

| Top width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com