Manufacturing method of combined ball clack for high-pressure double-valve-seat track ball valve

A manufacturing method and double valve seat technology, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as stuck combination balls, valves cannot be opened, and material creep, etc., to solve dirt deposition, start-up, etc. The effect of fast closing speed and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

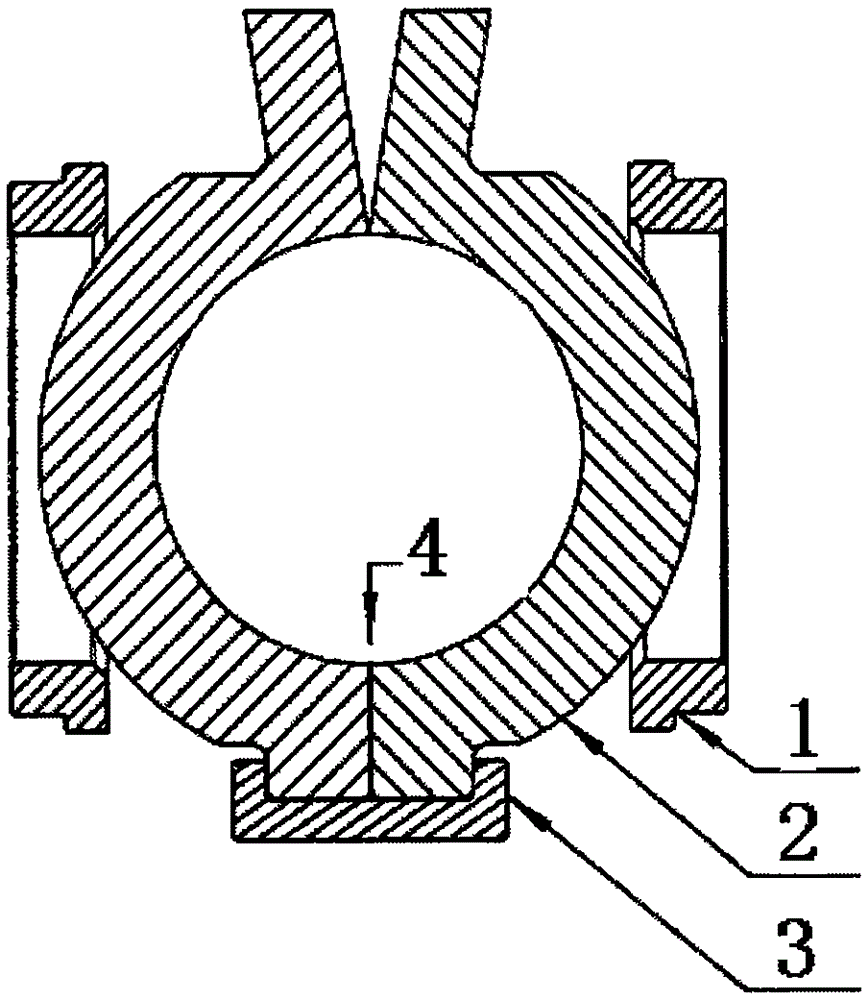

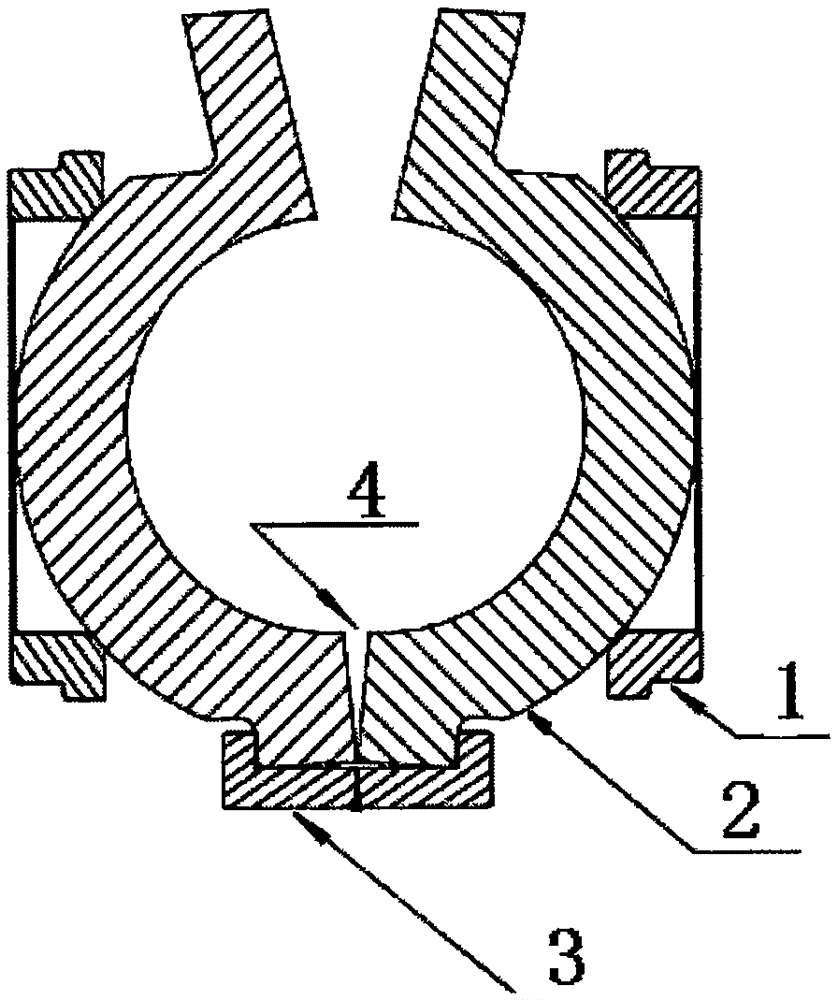

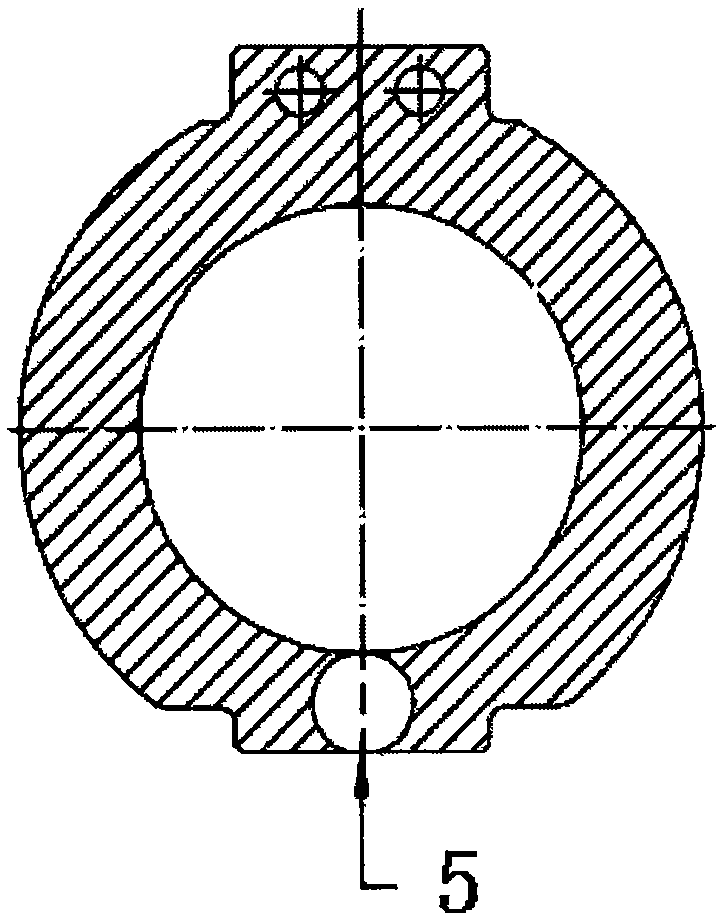

[0016] As shown in the figure, the present invention includes a valve seat 1, a ball valve 2, a shaft sleeve 3, a central joint 4, a circular through hole 5, and a roller 6. The valve cavity of the ball valve is equipped with two valve seats 1 and a ball. The ball is composed of two ball petals 2. The bottom end of the ball is equipped with a shaft sleeve 3. The upper part of the ball is equipped with a combined type brace mechanism. The mechanism supports the opening and closing activities of the two ball petals. This product makes improvements to the sphere, such as image 3 , Figure 4 , Figure 5 , Figure 6 As shown: firstly, a cylindrical through hole is processed at the lower end of the central axis of the entire valve sphere; secondly, the sphere is symmetrically divided into left and right two ball petals 2; again, a roller 6 is processed according to the diameter of the cylindrical through hole 5 ; Then the roller 6 is put into the cylindrical through hole betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com