Fly ash activator and low-cost cement prepared by using fly ash activator

A technology of fly ash and activator, which is applied in the field of low-cost cement and fly ash activator, can solve the problems of concrete shrinkage and cracking, affect concrete performance, reduce concrete strength, etc., achieve enhanced construction performance, good activation function, no The effect of three waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

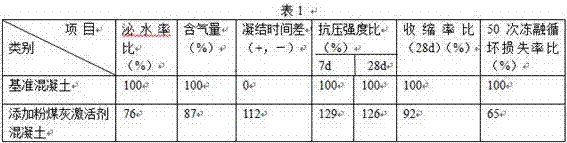

Examples

Embodiment 2

[0011] Fly ash activator embodiment 2, prepare raw material according to following proportioning: 30 kilograms of sodium sulfate, 40 kilograms of potassium aluminum sulfate, 3 kilograms of triethanolamine, 5 kilograms of sodium gluconate, 1.5 kilograms of citric acid and 35 kilograms of silicon powder; With embodiment 1.

Embodiment 3

[0012] Fly ash activator embodiment 3, prepare raw material according to following proportioning: 40 kilograms of sodium sulfate, 50 kilograms of potassium aluminum sulfate, 4.5 kilograms of triethanolamine, 5 kilograms of sodium gluconate, 2 kilograms of citric acid and 20 kilograms of silicon powder; With embodiment 1.

Embodiment 4

[0013] Fly ash activator embodiment 4, prepare raw material according to following proportioning: 35 kilograms of sodium sulfate, 60 kilograms of potassium aluminum sulfate, 5 kilograms of triethanolamine, 4 kilograms of sodium gluconate, 1.8 kilograms of citric acid and 33 kilograms of silicon powder; With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com