Online observation method and device for gas-liquid-solid phase abrasive particle flow rotational flow field

A technology of abrasive particle flow and flow field, which is applied to measuring devices, parts of grinding machine tools, grinding/polishing equipment, etc., to achieve the effect of improving visibility and predictability, and good guiding significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

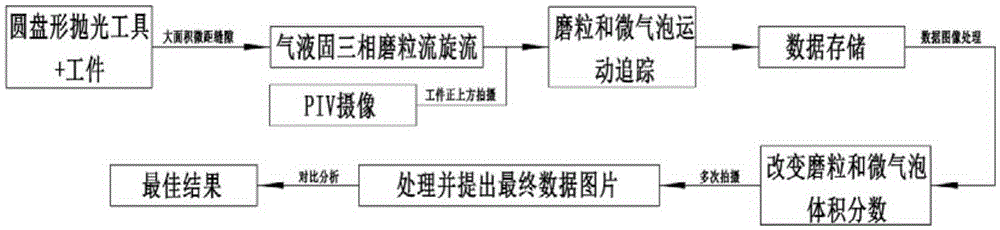

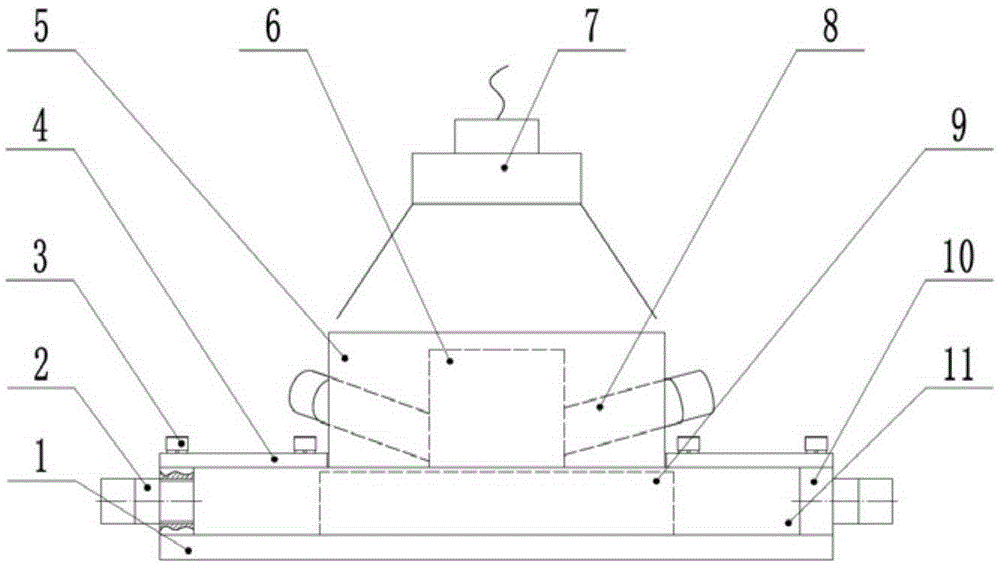

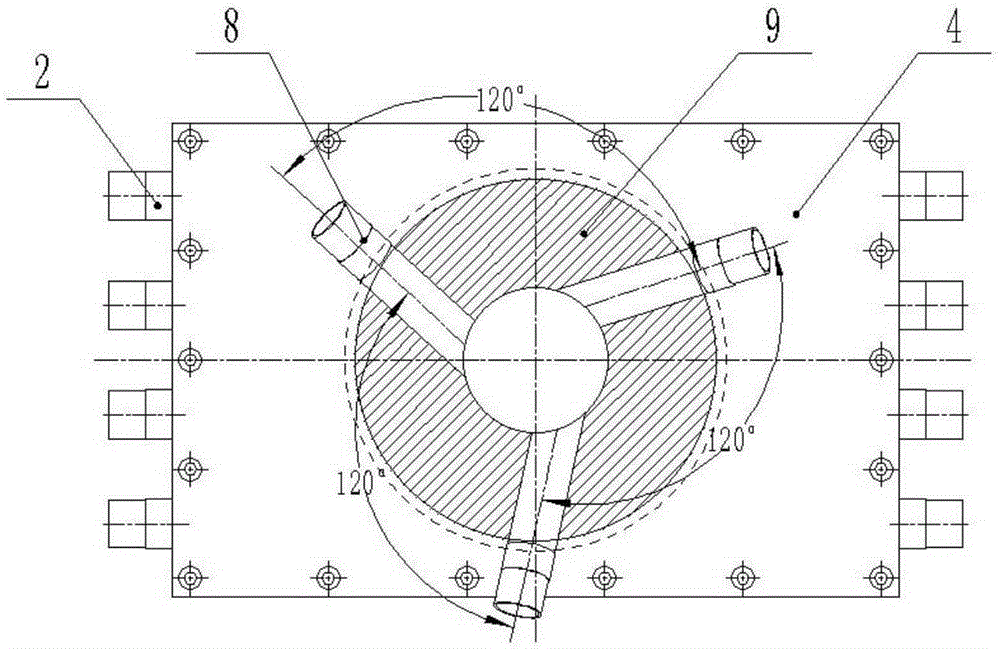

[0034] like Figure 1~4 As shown, an on-line observation method of gas-liquid-solid three-phase abrasive flow swirling flow field, the technical idea is: the particle image velocimetry camera in the particle image velocimetry equipment is installed directly above the polishing tool, and the The external abrasive flow delivery system injects the pre-mixed uniform gas-liquid-solid three-phase abrasive flow from the abrasive flow container into the polishing tool through the abrasive flow output pipe. When the particle image velocimetry camera starts to capture images and data, stop shooting after the gas-liquid-solid three-phase abrasive flow forms a stable gas-liquid-solid three-phase swirl flow field, and change the abrasive grains and For the ratio of the air bubbles, multiple shots were taken, and finally the data processing and extraction were completed in the processor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com