A method for reducing the oil content of fried potato chips

A technology of potato and oil content, applied in food coating, function of food ingredients, food science, etc., can solve the problem of insignificant oil reduction effect, reduce the total oil content, surface oil content and surface penetration oil content of potato crisps etc. to achieve the effect of reducing the total oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

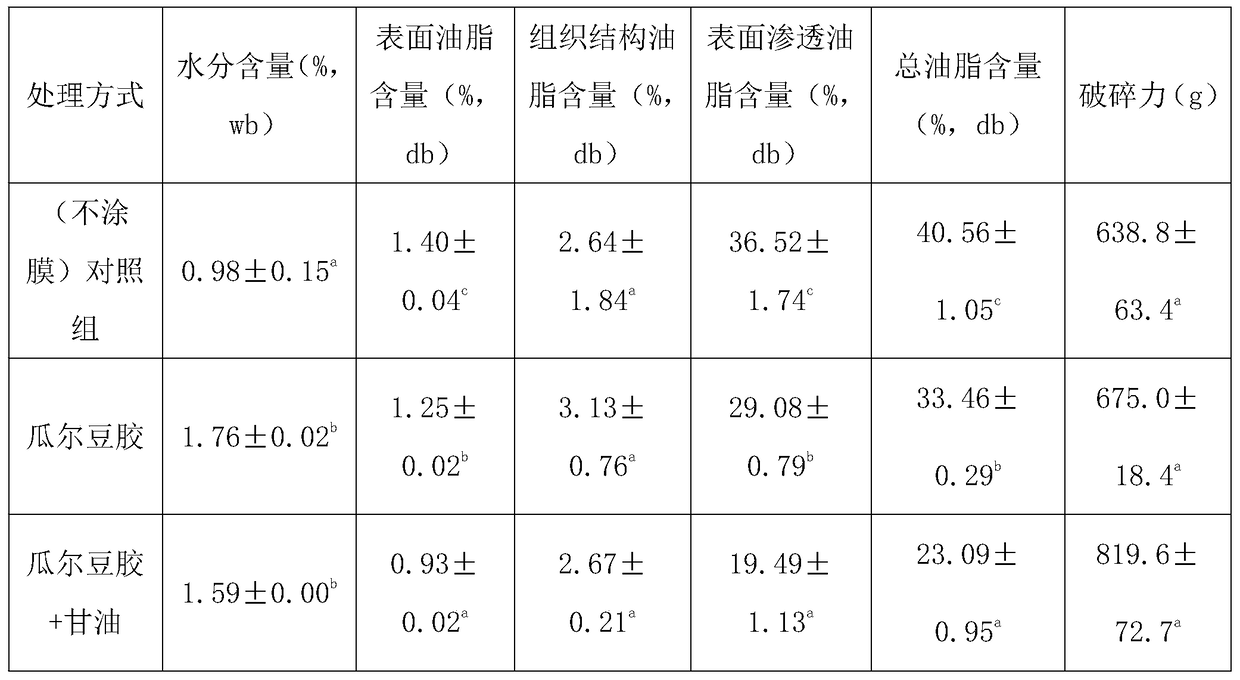

[0021] Wash and slice the potatoes, and use a mold to prepare a disc sample with a diameter of 22mm, soak it in a color-protecting solution of 0.6% vitamin C, 1.0% citric acid and 0.76% calcium chloride, and put the above-mentioned potato slices at 95 ° C. Blanched for 5 minutes under the condition of temperature, took it out and drained, then transferred the sample to a mixed solution of 1% guar gum and 8% glycerin, and coated it at 40°C for 3 minutes. The above coating samples were cooled to room temperature, and fried at 180°C for 8 minutes. After the above-mentioned fried samples were dried to a constant temperature, the fat content in the fried samples was measured by a fat analyzer. The following table shows the moisture content, oil content and texture of fried potato chips.

[0022]

Embodiment 2

[0024] Wash and slice the potatoes, and use a mold to prepare a disc sample with a diameter of 22 mm, soak it in a color-protecting solution of 0.4% vitamin C, 1.2% citric acid and 0.8% calcium chloride, and put the above-mentioned potato slices at 80 ° C. It was blanched for 6 minutes under the condition of temperature, drained after taking it out, and then the sample was transferred to a mixed solution of 0.8% guar gum and 10% glycerin, and coated at 42°C for 2 minutes. The above coating samples were cooled to room temperature, and fried at 160° C. for 10 minutes. After the above-mentioned fried samples were dried to a constant temperature, the fat content in the fried samples was measured by a fat analyzer. The moisture content of fried potato chips (1.60±0.17%), surface oil content (1.05±0.05%), tissue structure oil content (2.77±0.25%), surface penetration oil content (19.78±0.84%), total oil content (25.07±1.02%) and crushing force (811±54.2g), both are close to the dat...

Embodiment 3

[0026] Wash and slice the potatoes, and use a mold to prepare a disc sample with a diameter of 22 mm, soak it in a color-protecting solution of 0.8% vitamin C, 0.8% citric acid and 0.6% calcium chloride, and put the above-mentioned potato slices at 85 ° C. Blanched for 5min30s under the condition of temperature, took it out and drained, then transferred the sample to a mixed solution of 1.2% guar gum and 6% glycerin, and coated it at 39°C for 4min. The above coating samples were cooled to room temperature, and fried at 200°C for 6 minutes. After the above-mentioned fried samples were dried to a constant temperature, the fat content in the fried samples was measured by a fat analyzer. The moisture content of fried potato chips (1.71±0.23%), surface oil content (0.91±0.09%), tissue structure oil content (2.54±0.45%), surface penetration oil content (19.32±0.98%), total oil content (22.98±0.89%) and crushing force (799±74.3g), close to the data of the row of guar gum+glycerin in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com