White steam filature production technology

A production process and technology of white silk, which is used in silk fiber production, silk reeling, and cleaning/classification of silkworm cocoons. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

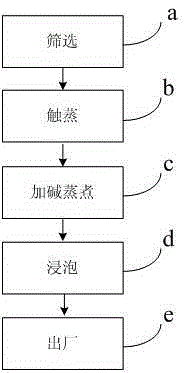

[0031] a. Screening: Use the cocoon peeling machine to strip the dried silk cocoons, remove unusable reeled cocoons, remove yellow class cocoons, rotten cocoons, inner printed cocoons, raw wood-shaped cocoons and double palace cocoons, and then board the car cocoon metering;

[0032] b. Three-stage touch steaming: send quantitatively packaged cocoons into steam touch steaming. The steam touch steaming is divided into three stages. The first stage maintains a pressure of 5Mpa, a temperature of 70 degrees Celsius, and a time of 5 hours. The second stage maintains a pressure of 8Mpa, temperature 90 degrees Celsius, time 12 hours, the third stage maintains pressure at 8Mpa, temperature 90 degrees Celsius, time 6 hours;

[0033] c. Cooking with alkali: the outer layer of the cocoon is cooked by the vacuum osmotic cocoon cooking machine. When cooking, add soap powder and a small amount of detergent, measure the pH with pH test paper to 9.5, and cook for more than half an hour;

[0...

Embodiment 2

[0037] a. Screening: Use the cocoon peeling machine to strip the dried silk cocoons, remove unusable reeled cocoons, remove yellow class cocoons, rotten cocoons, inner printed cocoons, raw wood-shaped cocoons and double palace cocoons, and then board the car cocoon metering;

[0038] b. Three-stage steaming: send quantitatively packaged silkworm cocoons into steaming steaming. The steaming steaming is divided into three stages. The first stage maintains a pressure of 8Mpa, a temperature of 90 degrees Celsius, and a time of 5 hours. The second stage maintains a pressure of 10Mpa, temperature 100 degrees Celsius, time 12 hours, the third stage maintains pressure at 5Mpa, temperature 70 degrees Celsius, time 6 hours;

[0039] c. Cooking with alkali: the outer layer of the cocoon is cooked by the vacuum osmotic cocoon cooking machine. When cooking, add soap powder and a small amount of detergent, measure the pH to 10 with pH test paper, and cook for more than half an hour;

[004...

Embodiment 3

[0043] a. Screening: Use the cocoon peeling machine to strip the dried silk cocoons, remove unusable reeled cocoons, remove yellow class cocoons, rotten cocoons, inner printed cocoons, raw wood-shaped cocoons and double palace cocoons, and then board the car cocoon metering;

[0044] b. Three-stage touch steaming: send quantitatively packaged cocoons into steam touch steaming. The steam touch steaming is divided into three stages. The first stage maintains a pressure of 6Mpa, a temperature of 90 degrees Celsius, and a time of 5 hours. The second stage maintains a pressure of 9Mpa, temperature 110 degrees Celsius, time 12 hours, the third stage maintains pressure at 6Mpa, temperature 70 degrees Celsius, time 6 hours;

[0045] c. Cooking with alkali: the outer layer of the cocoon is cooked by the vacuum osmotic cocoon cooking machine. When cooking, add soap powder and a small amount of detergent, measure the pH with pH test paper to 9.8, and cook for more than half an hour;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com