Vacuum energy storage fixed-wing aircraft take-off catapult

An aircraft take-off and energy storage technology, which is applied in the direction of launch/tow transmission, can solve the problems of short maintenance cycle, difficult maintenance work, complex system, etc., and achieves low requirements for manufacturing materials, full use of space, and flexible installation positions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

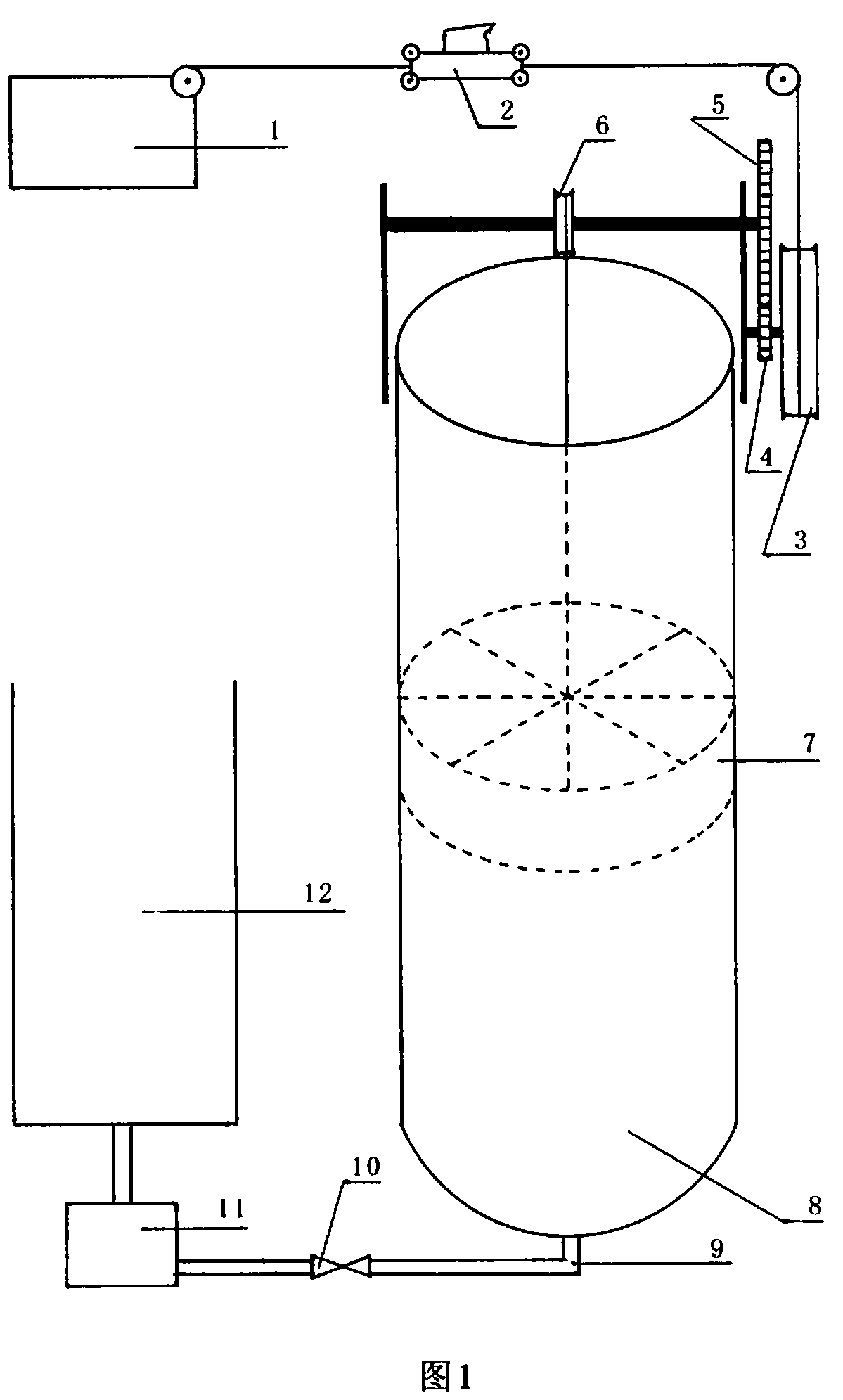

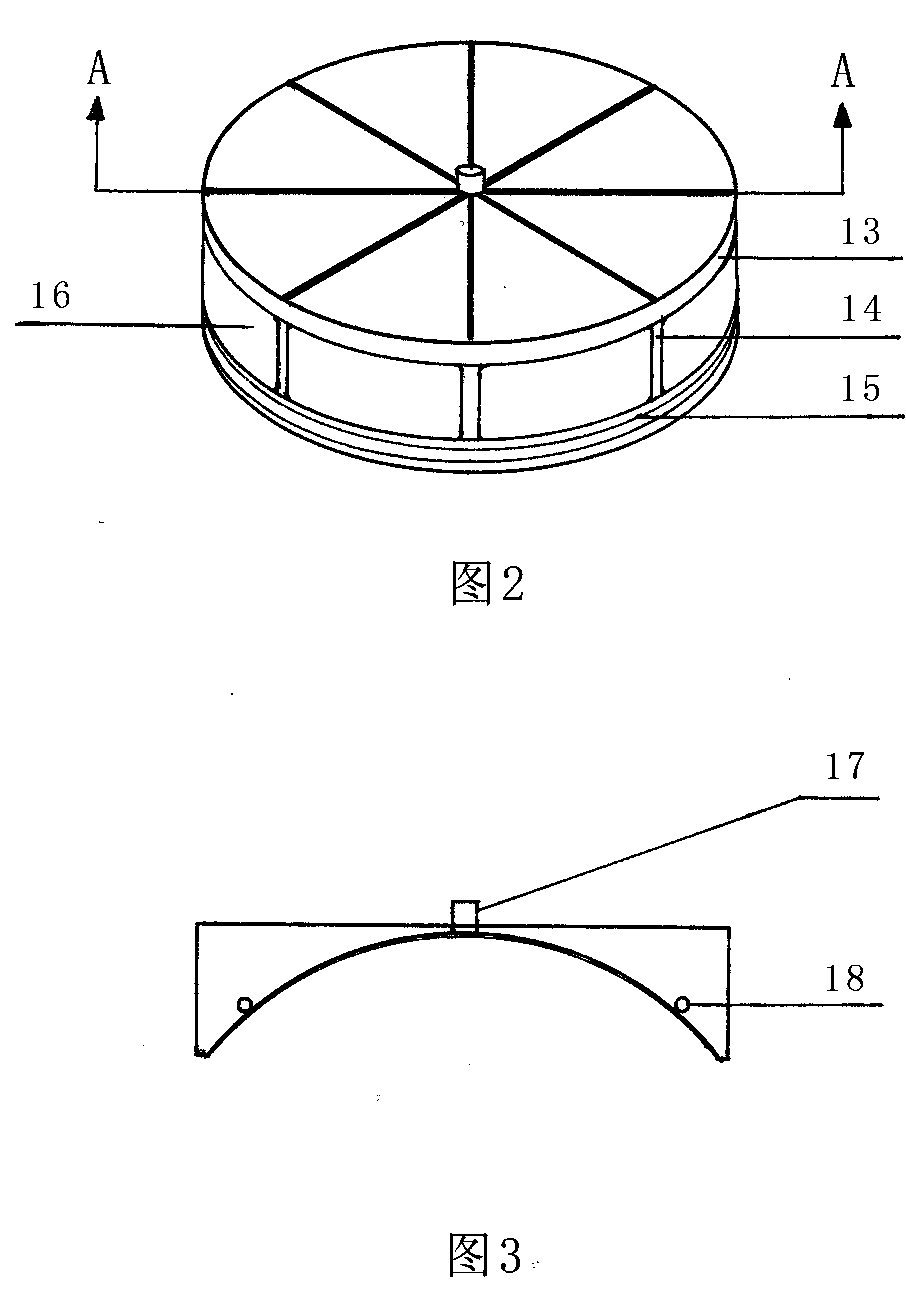

[0016]First, calculate the relevant data of the embodiment. For the convenience of calculation, the value of atmospheric pressure is 1kg / cm^2. After conversion, the pressure per square meter is 10 tons; the acceleration of gravity g is 10m / s; the weight of the piston is 9 tons through the counterweight, and its gravity is assumed to be exactly Offset the friction and other resistance of the system during ejection; the diameter of the vacuum cylinder is 6 meters, and the effective stroke of the piston is 11 meters. Then the pressure area of the piston is 3.14x3^2=28.26 square meters, and the atmospheric pressure is 28.26x10=282.6 tons, which can be used for ejection. . After 9 times the acceleration from the small cable pulley to the large cable pulley, the net pulling force of the towing aircraft is 282.6 / 9=31.4 tons, and the towing distance is 11x9=99 meters. This distance can be increased by raising the oil level of the vacuum cylinder. Scaled down to accommodate ejectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com