Three-dimensional carving machine

A three-dimensional engraving machine and column technology, applied in the field of machinery, can solve the problems of single function of engraving machine, complicated tool holder connection, product scrapping, etc., and achieve the effects of improving engraving accuracy, stable translation action and reducing occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

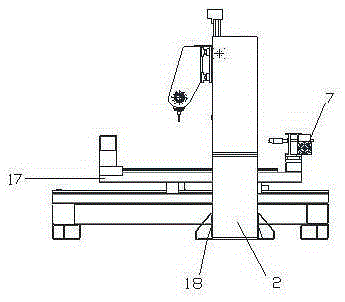

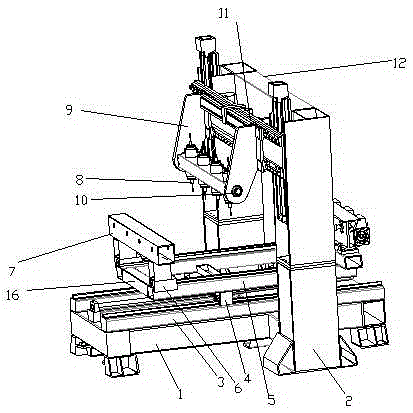

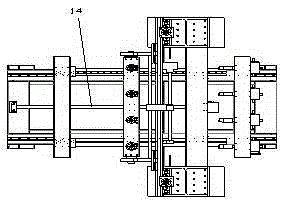

[0024] Such as Figure 1 to Figure 4 The three-dimensional engraving machine shown includes a frame, an engraving mechanism arranged on the frame, and a driving mechanism for driving the engraving machine. Wherein, the frame includes a base 1 , columns 2 arranged on both sides of the base 1 , a beam 12 , and a bottom beam 13 . The uprights 2 are arranged on both sides of the base 1, and the bottoms of the two uprights 2 are fixedly connected through the bottom beam 13, and the tops of the two uprights 2 are fixedly connected through the crossbeam 12, and pads are externally connected to the bottom of the uprights 2 18. Increase the contact area of the column.

[0025] When the engraving machine was working, the engraving mechanism included an engraving platform 17, a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com