Artificial wooden multilayer glued die-pressed door sheet and manufacturing process thereof

A production process and wood technology, applied in the field of artificial wood multi-layer glued molded door panels and its production process, to achieve the effects of outstanding strength and stability, simple production process, and low formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

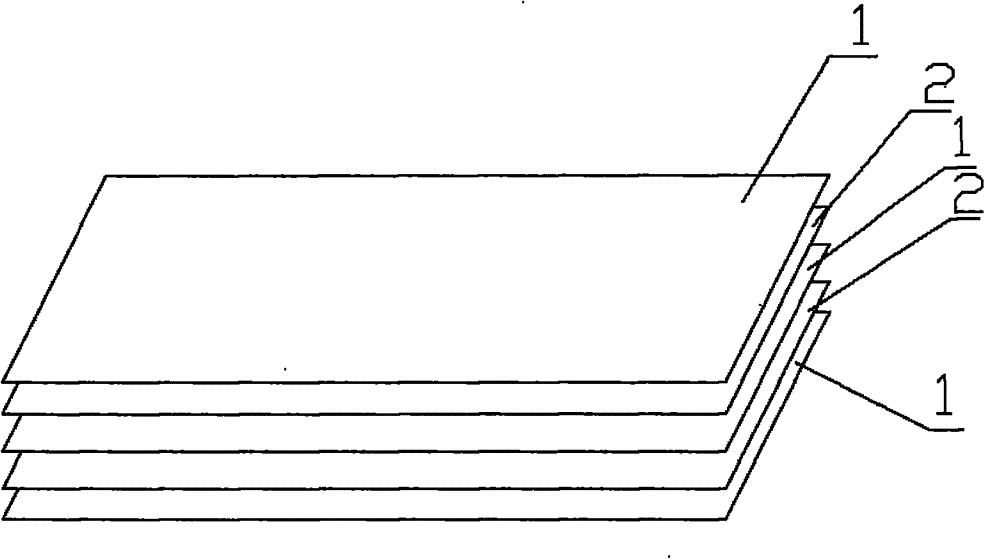

[0036] An artificial wooden multi-layer glued molded door panel is characterized in that it comprises:

[0037] The first layer is a horizontally laid veneer 1, wherein the length is horizontal and the width is vertical, and the vertical direction is the natural texture of the veneer;

[0038] The second layer is a vertically laid veneer 2 laid on the first layer;

[0039] The third layer is a horizontally laid veneer 1 laid on the second layer;

[0040] The fourth layer is the veneer 2 laid vertically on the third layer;

[0041] The fifth layer is a horizontally laid veneer 1 laid on the fourth layer;

[0042] The mixed glue for bonding that is coated on the front and back of the second layer and the fourth layer.

[0043] As a better embodiment, the moisture content of the veneer is 10%. The moisture content of the veneer is controlled, and the whole production process does not require water softening treatment, so that the depth of the molded pattern can reach more tha...

Embodiment 2

[0058] An artificial wooden multi-layer glued molded door panel is characterized in that it comprises:

[0059] The first layer is a horizontally laid veneer 1, wherein the length is horizontal and the width is vertical, and the vertical direction is the natural texture of the veneer;

[0060] The second layer is a vertically laid veneer 2 laid on the first layer;

[0061] The third layer is a horizontally laid veneer 1 laid on the second layer;

[0062] The fourth layer is the veneer 2 laid vertically on the third layer;

[0063] The fifth layer is a horizontally laid veneer 1 laid on the fourth layer;

[0064] The mixed glue for bonding that is coated on the front and back of the second layer and the fourth layer.

[0065] As a better embodiment, the moisture content of the veneer is 12.5%. The moisture content of the veneer is controlled, and the whole production process does not require water softening treatment, so that the depth of the molded pattern can reach more t...

Embodiment 3

[0080] An artificial wooden multi-layer glued molded door panel is characterized in that it comprises:

[0081] The first layer is a horizontally laid veneer 1, wherein the length is horizontal and the width is vertical, and the vertical direction is the natural texture of the veneer;

[0082] The second layer is a vertically laid veneer 2 laid on the first layer;

[0083] The third layer is a horizontally laid veneer 1 laid on the second layer;

[0084] The fourth layer is the veneer 2 laid vertically on the third layer;

[0085] The fifth layer is a horizontally laid veneer 1 laid on the fourth layer;

[0086] The mixed glue for bonding that is coated on the front and back of the second layer and the fourth layer.

[0087] As a better embodiment, the moisture content of the veneer is 15%. The moisture content of the veneer is controlled, and the whole production process does not require water softening treatment, so that the depth of the molded pattern can reach more tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com