Preparation method for novel jelly

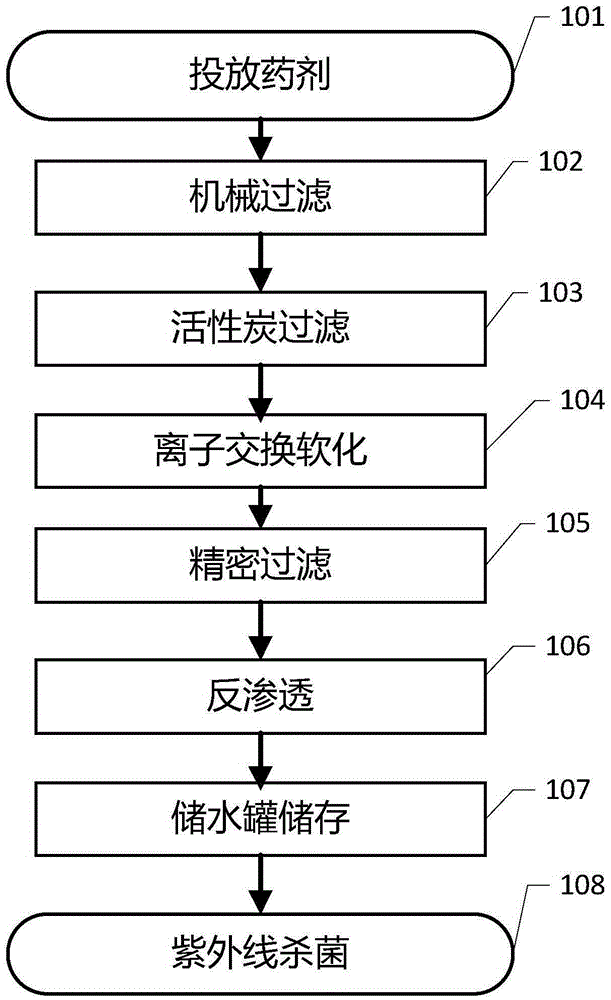

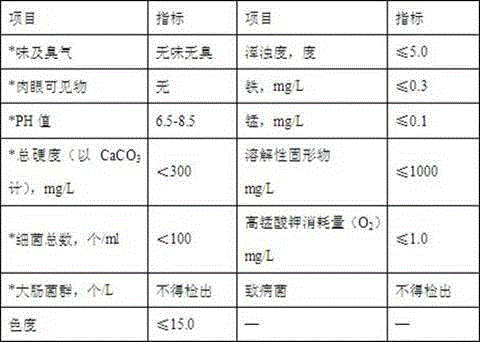

A jelly, a new type of technology, applied in the fields of food science, application, food ingredients, etc., can solve the problems of low nutritional value, no health care effect, harmful to the health of consumers, etc., and achieve the effect of high water quality, no syneresis, and improved hygiene standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

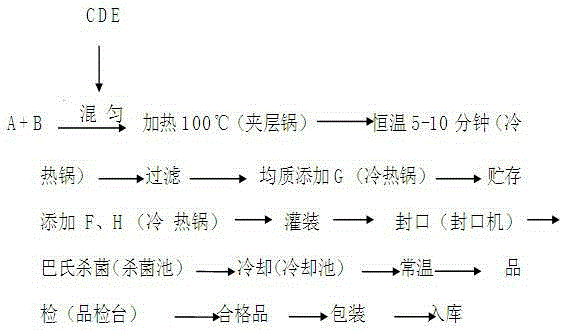

Method used

Image

Examples

Embodiment 1

[0059] A novel method for preparing jelly, wherein every 100g of yogurt crystal jelly is mainly prepared from the following components:

[0060] White sugar 6g

[0061] High fructose syrup 6g

[0062] AK sugar 0.015g

[0063] Gel 0.7g

[0064] Sodium carboxymethyl cellulose 0.6g

[0065] Coagulant and thickener 0.1g

[0066] Acidity Regulator 0.45g

[0067] Food flavor 0.07g

[0068] The balance is process water.

[0069] Wherein, the gelling agent includes carrageenan, Wenlun gum, potassium alginate, wherein carrageenan is 0.3g, Wenlun gum is 0.3g, potassium alginate is 0.1g, coagulant and thickener include potassium chloride and calcium lactate , wherein potassium chloride 0.05g, calcium lactate 0.05g, acidity regulators include malic acid, citric acid and sodium citrate, wherein malic acid is 0.1g, citric acid is 0.2g, and sodium citrate is 0.15g.

[0070] (1) Taking materials: Weigh 6g white granulated sugar, 6g fructose syrup, 0.015g AK sugar, 0.7g gelling agent, ...

Embodiment 2

[0083] A novel method for preparing jelly, wherein every 100g of yogurt crystal jelly is mainly prepared from the following components:

[0084] White sugar 5g

[0085] High fructose syrup 6g

[0086] AK sugar 0.02g

[0087] Gel 0.7g

[0088] Sodium carboxymethyl cellulose 0.4g

[0089] Coagulant and thickener 0.08g

[0090] Acidity Regulator 0.55g

[0091] Food flavor 0.07g

[0092] The balance is process water.

[0093] Wherein, the gelling agent includes carrageenan, Wenlun gum, potassium alginate, wherein carrageenan is 0.3g, Wenlun gum is 0.3g, potassium alginate is 0.1g, coagulant and thickener include potassium chloride and calcium lactate , wherein potassium chloride 0.04g, calcium lactate 0.04g, acidity regulators include malic acid, citric acid and sodium citrate, wherein malic acid is 0.2g, citric acid is 0.2g, and sodium citrate is 0.15g.

[0094] (1) Taking materials: Weigh 5g of white granulated sugar, 6g of fructose syrup, 0.02g of AK sugar, 0.7g of gell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com