Safety protection socket

A safety protection and socket technology, applied in electrical components, coupling devices, circuits, etc., can solve problems such as increasing system complexity, electric shock, and reducing reliability, achieving increased cost and selling price, high safety performance, and R&D investment. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

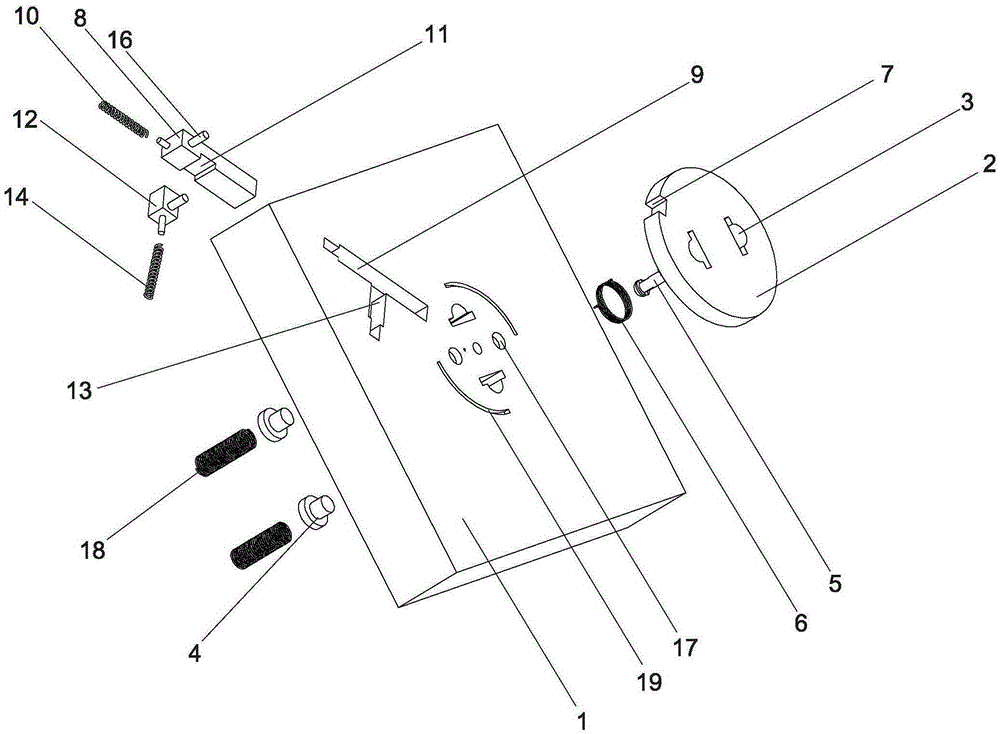

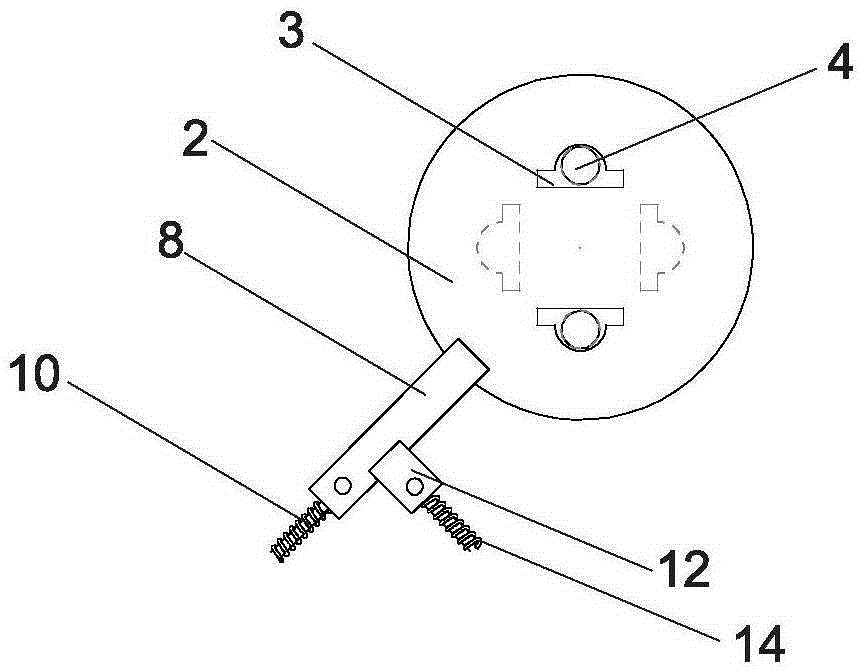

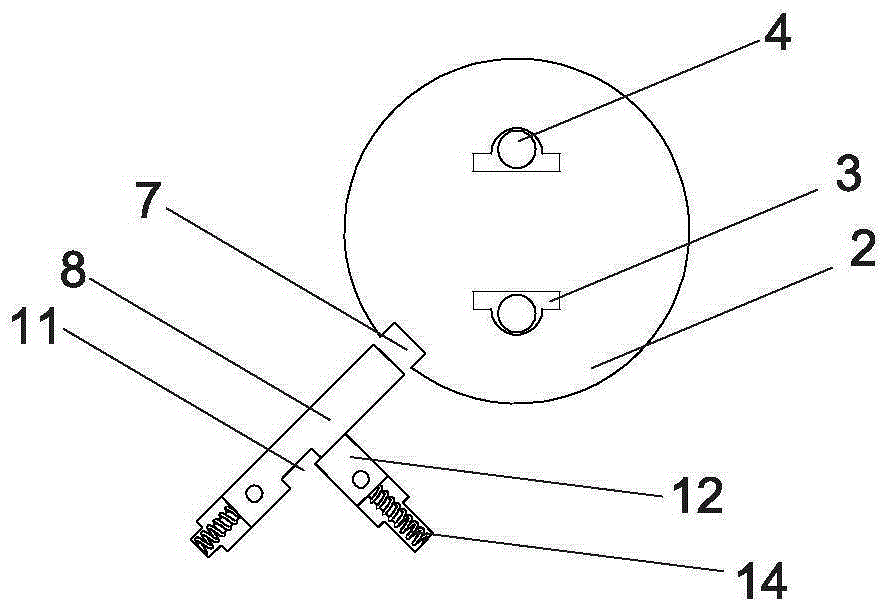

[0044] Such as figure 1 , figure 2 , image 3 , Figure 4 , Image 6 As shown, a two-hole safety protection socket includes a socket body 1 and a circular protective cover 2 made of plastic. The protective cover 2 is integrally provided with a rotating shaft 5, and the bottom end of the rotating shaft 5 is provided with a slightly enlarged diameter. The chuck and the slit provided along the shaft section, the slit runs through the chuck, the top shell of the socket body 1 is provided with a shaft hole adapted to the shaft 5 and two limit grooves 19, and the bottom shell inside the socket body 1 There is also a shaft hole on the top, and the chuck can pass through the shaft holes at the top and bottom of the socket body 1 after closing along the gap. The rotating shaft 5 passes through the rotating shaft hole of the top shell of the socket body 1 and is rotatably connected with the top shell of the socket body 1, so that the protective cover 2 is rotatably connected to the...

Embodiment 2

[0047] Such as Figure 7 As shown, the locking mechanism includes a password lock pin 15, which is provided with a password controller and a telescopic pin. The width of the telescopic pin is adapted to the width of the notch 7, and the axis of the notch 7 is parallel to the sliding path of the telescopic pin. When the socket is not in use, the pop-up telescopic pin is stuck in the gap 7, and the protective cover 2 is locked. If electricity is needed, the authorization code must be input, and the retractable pin can be retracted, and then the protective cover 2 is unlocked, so that the plug can be inserted to get electricity. All the other are with embodiment 1.

Embodiment 3

[0049] Such as Figure 5As shown, the protective cover 2 is bow-shaped, and the through hole 3, the convex pin hole 17 and the elastic convex pin 4 are all one. Covered, the two holes of the through hole 3 and the convex pin hole 17 overlap and the elastic convex pin 4 pops up and inserts into the through hole 3; when the protective cover 2 is rotated 90° to the limit position, the through hole 3 overlaps with the live wire slot of the socket body 1 , at this time, the top of the neutral line slot of the socket body 1 is open, and is not blocked by the protective cover 2 . All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com