A power type cylindrical battery automatic casing machine

A cylindrical battery and power type technology, which is applied in the direction of primary battery, cylindrical shell battery/battery, assembled battery machine, etc., can solve the problems of difficult alignment between the shell and the battery cell, distortion, deformation and scrapping, and no assembly equipment, etc., to achieve The effect of small footprint, precise movement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

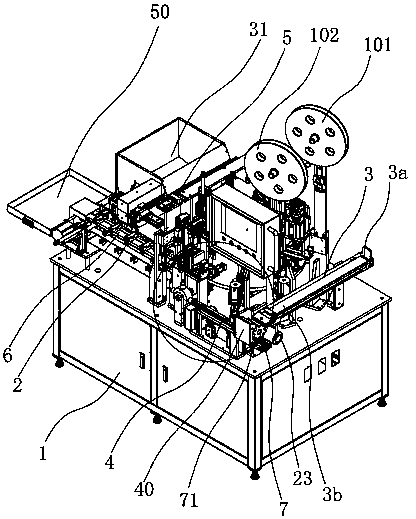

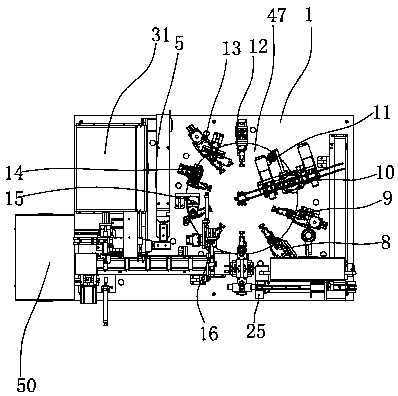

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

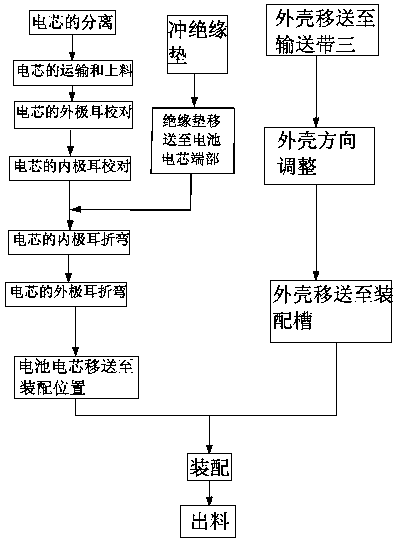

[0036] The shelling machine is suitable for the assembly and production of semi-finished cylindrical batteries, especially the production and assembly of 18650 cylindrical batteries. The battery cells need to be covered with a metal shell to improve protection strength and safety. The power cylindrical battery in the embodiment is automatically shelled. The machine is used for the assembly of the shell and the battery cell. Before the shell and the battery cell are assembled, an insulating pad must be installed at the end of the battery cell to ensure the accuracy of the position of the inner tab and the outer tab of the cylindrical battery.

[0037] like figure 1 , figure 2 and image 3 As shown, both ends of the cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com