Heterojunction solar cell and preparation method thereof

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of crystalline silicon wafer contamination, reduce battery fill factor, and reduce the surface passivation quality of crystalline silicon wafers, so as to improve passivation The effect of optimizing quality, improving fill factor and conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

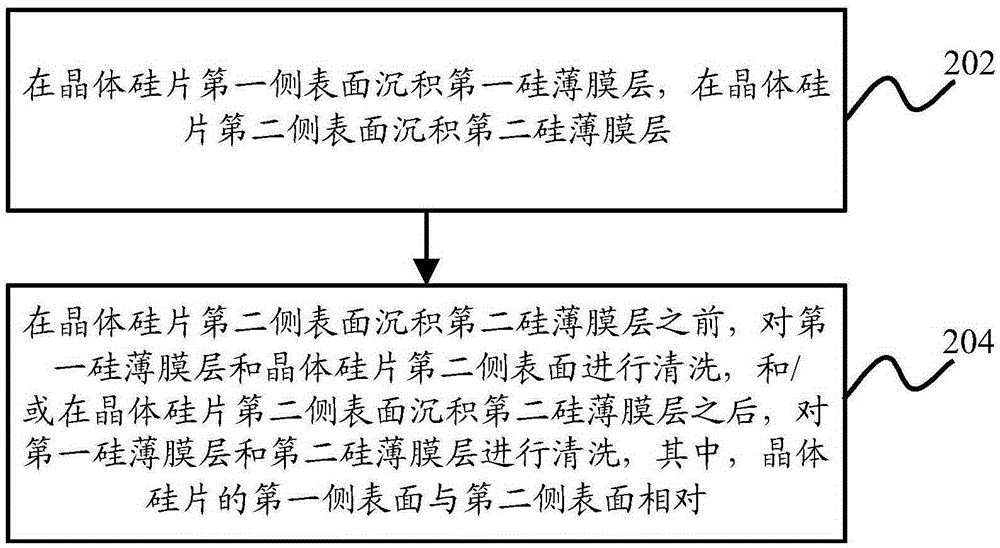

[0029] A method for preparing a heterojunction solar cell provided in an embodiment of the present invention, such as figure 2 shown, including:

[0030] Step 202, depositing a first silicon thin film layer on the first side surface of the crystalline silicon wafer, and depositing a second silicon thin film layer on the second side surface of the crystalline silicon wafer;

[0031] Step 204, before depositing the second silicon thin film layer on the second side surface of the crystalline silicon wafer, cleaning the first silicon thin film layer and the second side surface of the crystalline silicon wafer, and / or depositing the second silicon thin film layer on the second side surface of the crystalline silicon wafer After the silicon thin film layer is removed, the first silicon thin film layer and the second silicon thin film layer are cleaned, wherein the first side surface of the crystalline silicon wafer is opposite to the second side surface.

[0032] In the method pro...

Embodiment approach 1

[0035] Embodiment 1: Before depositing the second silicon thin film layer on the second side surface of the crystalline silicon wafer, the first silicon thin film layer and the second side surface of the crystalline silicon wafer are cleaned. This embodiment will be described in detail below in conjunction with the manufacturing process of the heterojunction solar cell. Such as image 3 As shown, the preparation process of heterojunction solar cells includes:

[0036] Step 302, texturizing and cleaning the crystalline silicon wafer, that is, performing texturing and cleaning on the crystalline silicon wafer to remove organic matter, metal contamination and oxides on the surface of the crystalline silicon wafer;

[0037] Step 304, depositing the first intrinsic layer I, that is, depositing the first intrinsic layer I on the first side surface of the crystalline silicon wafer after texturing and cleaning;

[0038] Step 306, depositing the doped layer P (or N) layer, that is, d...

Embodiment approach 2

[0047] Embodiment 2: After depositing the second silicon thin film layer on the second side surface of the crystalline silicon wafer, the first silicon thin film layer and the second silicon thin film layer are cleaned. This embodiment will be described in detail below in conjunction with the manufacturing process of the heterojunction solar cell. Such as Figure 4 As shown, the preparation process of heterojunction solar cells includes:

[0048] Step 402, texturizing and cleaning the crystalline silicon wafer, that is, performing texturing and cleaning on the crystalline silicon wafer to remove organic matter, metal contamination and oxides on the surface of the crystalline silicon wafer;

[0049] Step 404, depositing the first intrinsic layer I, that is, depositing the first intrinsic layer I on the first side surface of the crystalline silicon wafer after texturing and cleaning;

[0050] Step 406, depositing the doped layer P (or N) layer, that is, depositing the doped la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| open-circuit voltage | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com