Photoelectric sensor

A photoelectric sensor and photodiode technology, applied in the field of sensors, can solve the problems of high cost, bulky equipment, complex process, etc., and achieve the effects of low production cost, improved resolution, and uniform reflected light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

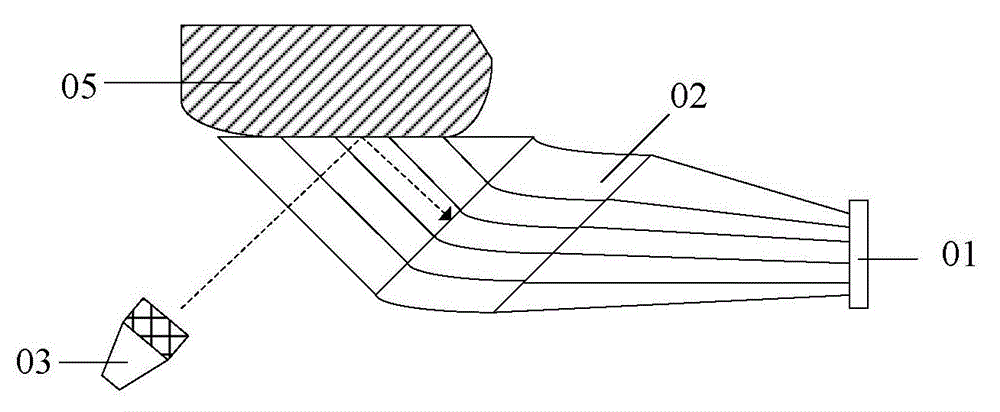

[0062] Existing photoelectric sensors generally have high production costs, large volume, and low resolution, making them difficult to apply to portable devices.

[0063] In order to solve the above technical problems, the present invention provides a photoelectric sensor with lower production cost, smaller volume and higher resolution, so that it can be better applied to portable devices.

[0064] The technical solution of the photoelectric sensor of the present invention will be described in detail below in conjunction with the accompanying drawings.

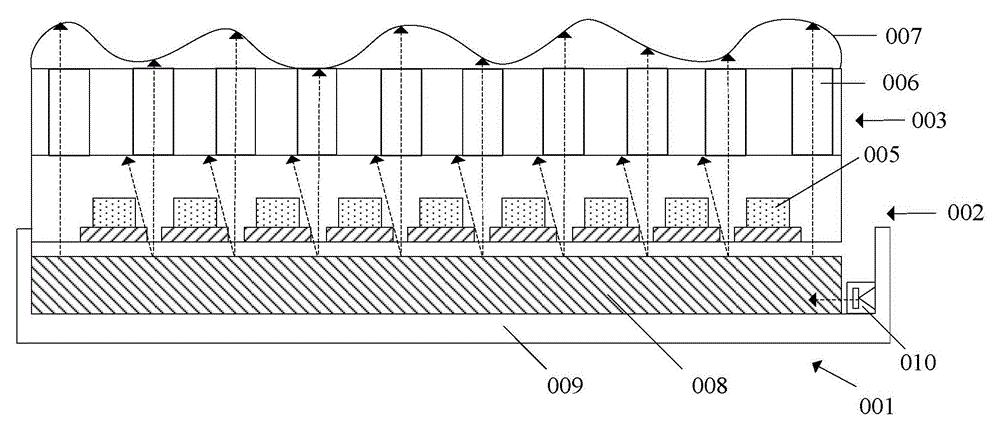

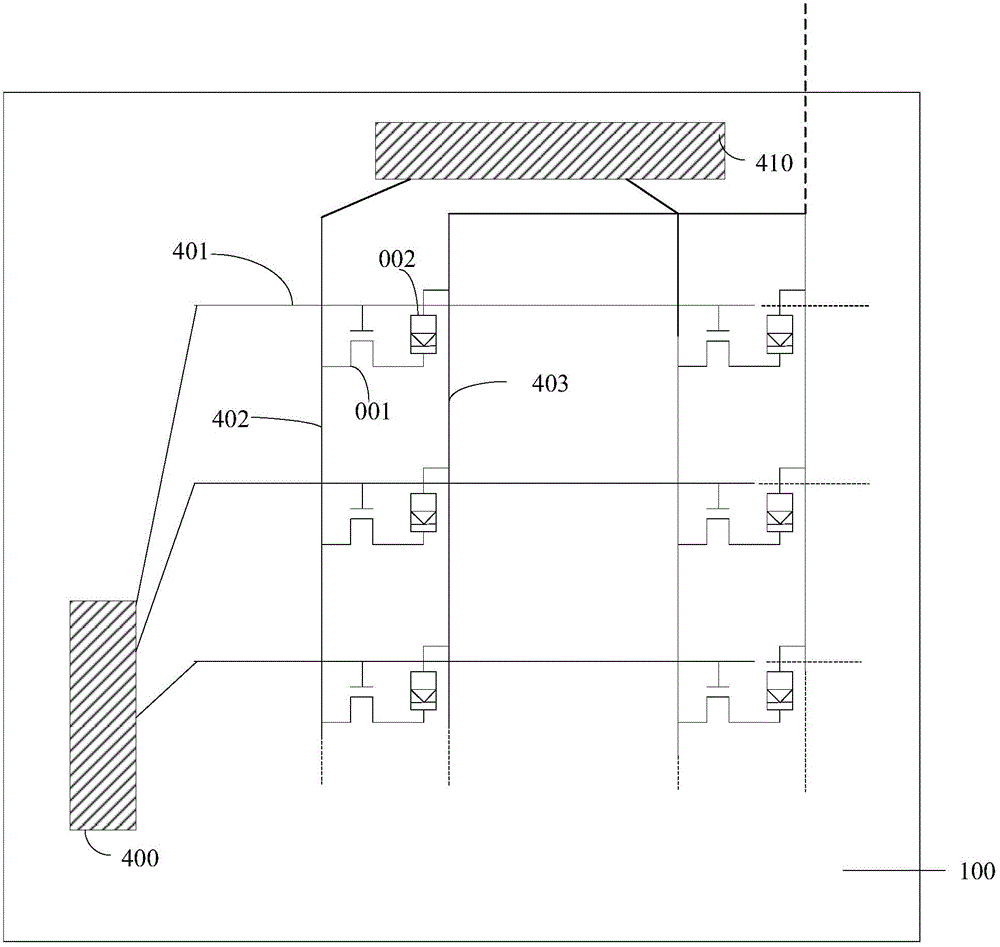

[0065] refer to figure 2 , shows a schematic cross-sectional view of the photoelectric sensor of the present invention. The photoelectric sensor of the present invention comprises:

[0066] A photosensitive structure 002, the photosensitive structure 002 includes a substrate 100 and a plurality of pixel units 005 on the substrate 100, the pixel units 005 include thin film transistors and photodiodes. It should be noted tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com