Display Panel Manufacturing System

A technology for manufacturing systems and display panels, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of wasting manpower, material resources and time, reducing factory production capacity, and high panel manufacturing costs, and improving production capacity. , The effect of speeding up the manufacturing progress and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

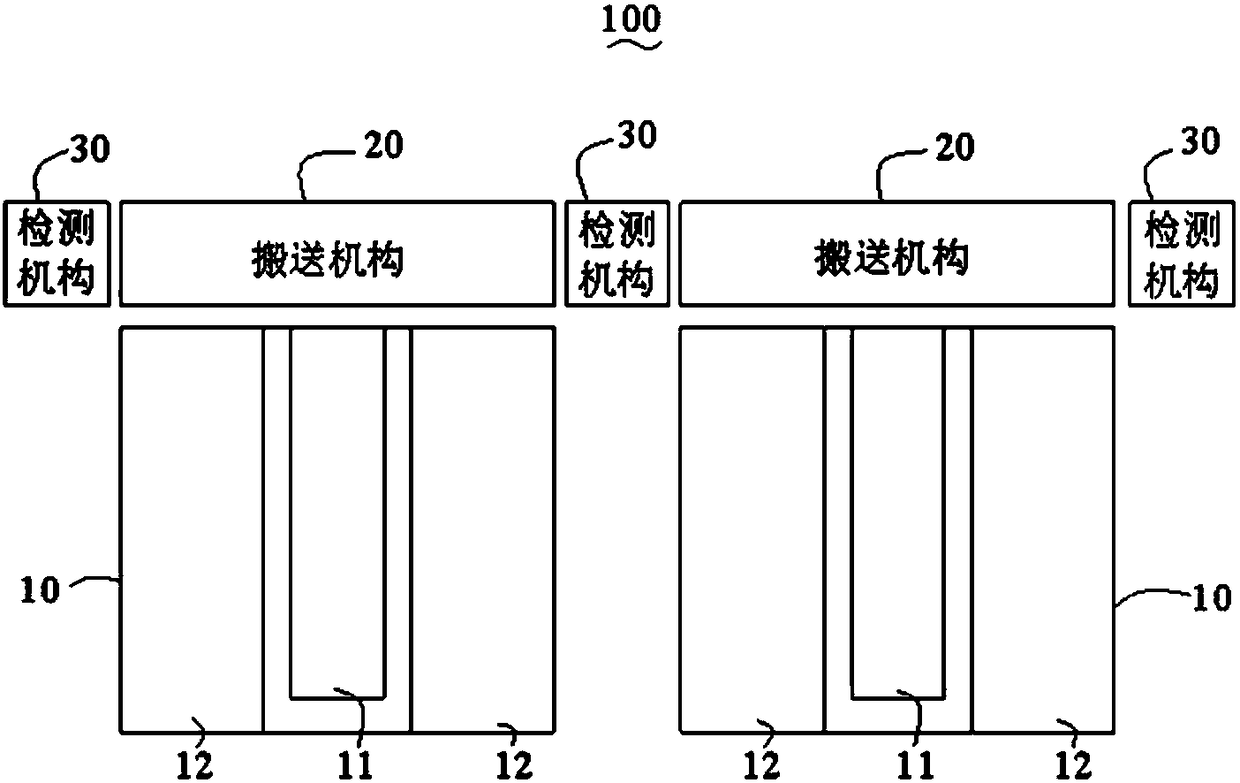

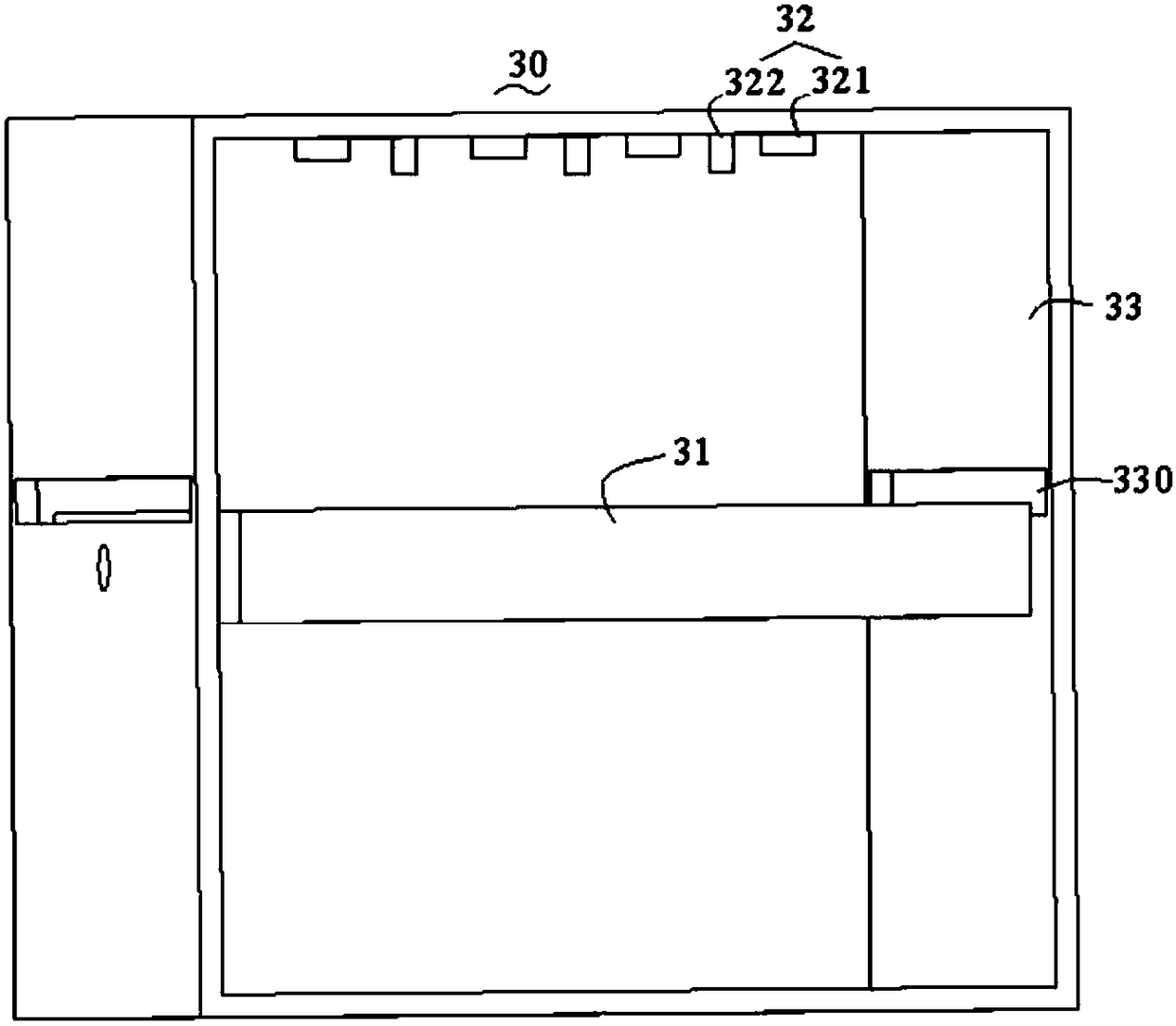

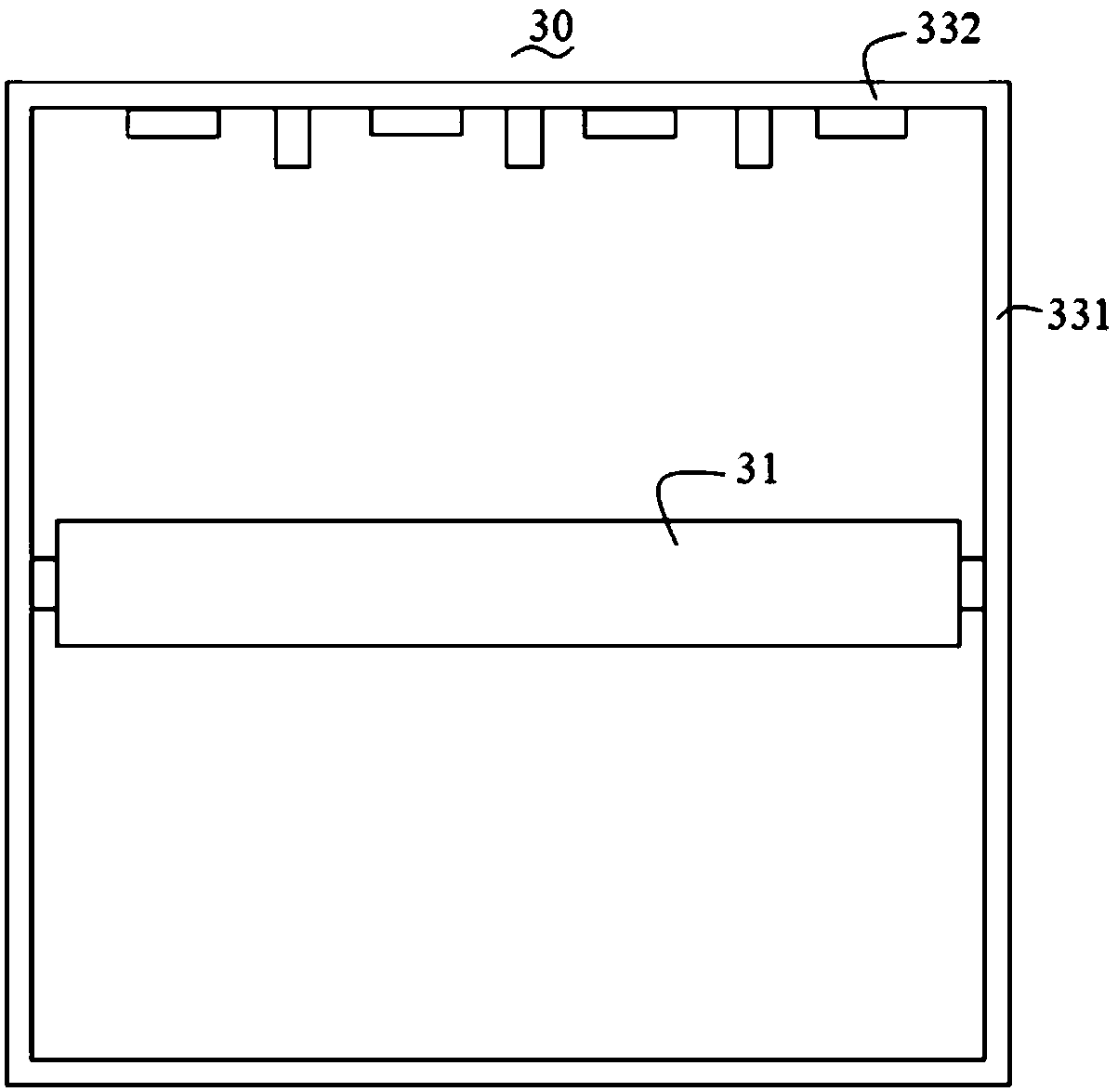

[0024] Please refer to Figure 1-Figure 8 , the display panel manufacturing system 100 of the present invention includes a processing station 10 , a transport mechanism 20 and a detection mechanism 30 .

[0025] The processing station 10 is used for processing the glass substrate 40 . In this embodiment, the processing station 10 includes a cleaning unit 11 and two processing units 12 . The cleaning unit 11 is located between the two processing units 12 . This embodiment is aimed at setting the stations with higher cleaning efficiency but lower processing efficiency, so as to improve the utilization efficiency of the cleaning unit 11 . In practical applications, when the time difference between the cleaning process and the processing process of a certain process is not too large, a processing station may only include a cleaning unit and a processing unit. The specific processing technology of the glass substrate 40 is not limited in the present invention, for example, it ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com