Three-dimensional photography technology based folded pipe field measurement method

A technology for on-site measurement and closing tubes, which is applied in the direction of measuring devices, special data processing applications, instruments, etc., can solve problems affecting measurement performance and work efficiency, increase cost investment, and cumbersome operation process, etc., to achieve a suitable large-scale Promote and apply, save time, measure safe and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

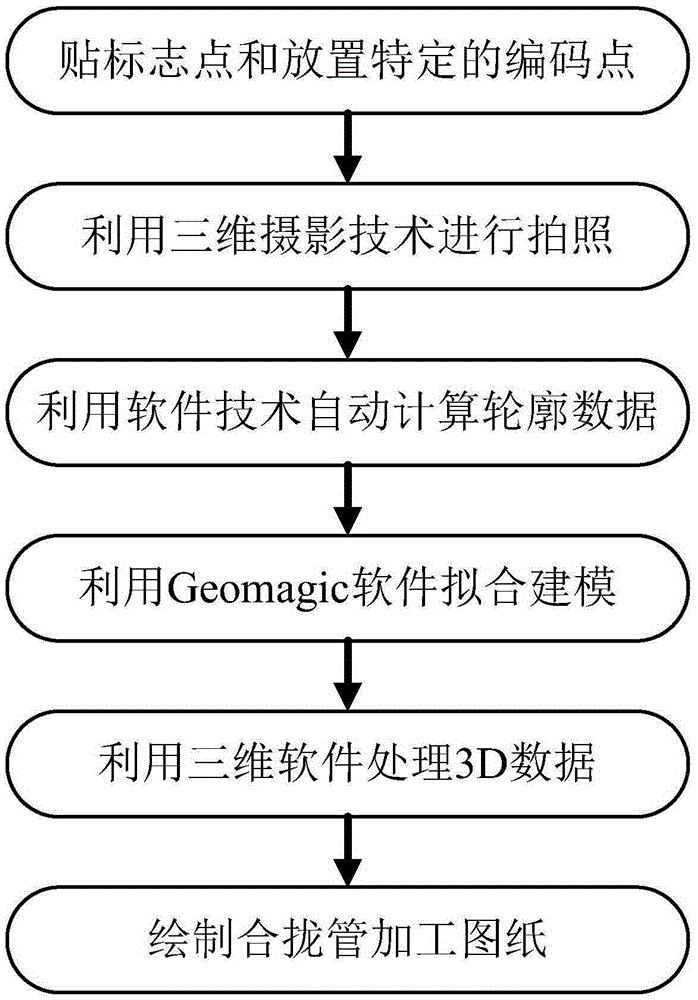

[0025] like figure 1 As shown, a method for on-site measurement of closed pipes based on three-dimensional photography technology includes the following steps:

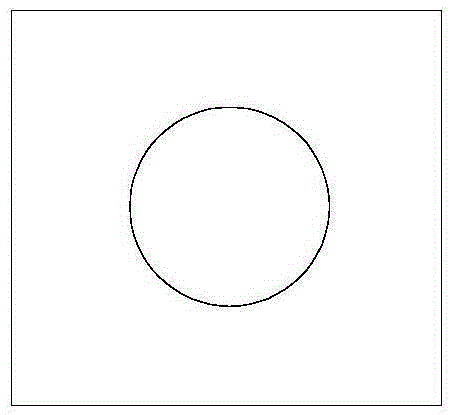

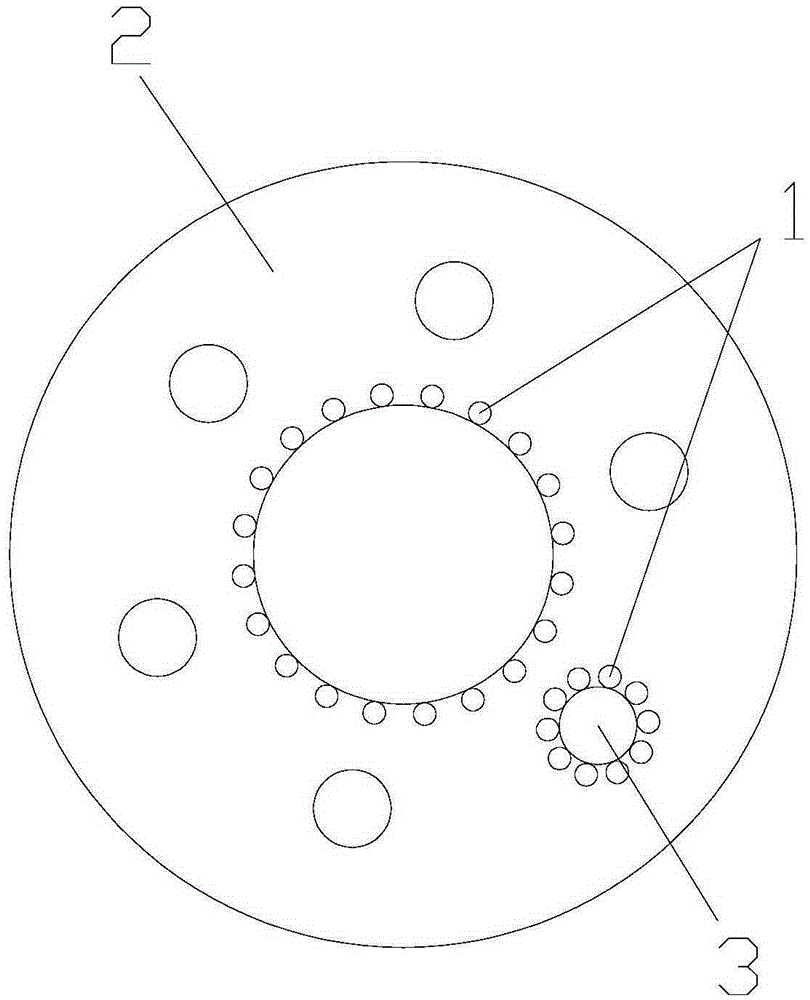

[0026] (1) At the end of the first flange 240cm away, a circle of marking points 1 is pasted around the first pipe 4, and the marking points 1 are as follows: figure 2 As shown, the center of the mark point 1 is a circular white point, surrounded by a square black background, and a circle of mark points 1 is pasted on the outer contour surface of the first flange 2; on the sealing surface side of the first flange 2, in it A mark point 1 is attached to the edge of a bolt hole 3, and 10 mark points 1 are attached to keep the circular edge aligned with the edge of the bolt hole 3, and 20 marks are also attached to the sealing surface of the first flange 2 along the inner contour of the first flange 2. A marker point 1 whose circular edge is aligned with the edge of the blue inner contour, such as image 3 and Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com