Task decoupling-based multi-robot collaboration welding path generation method

A multi-robot, welding path technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of lack of unified method for different workpieces and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

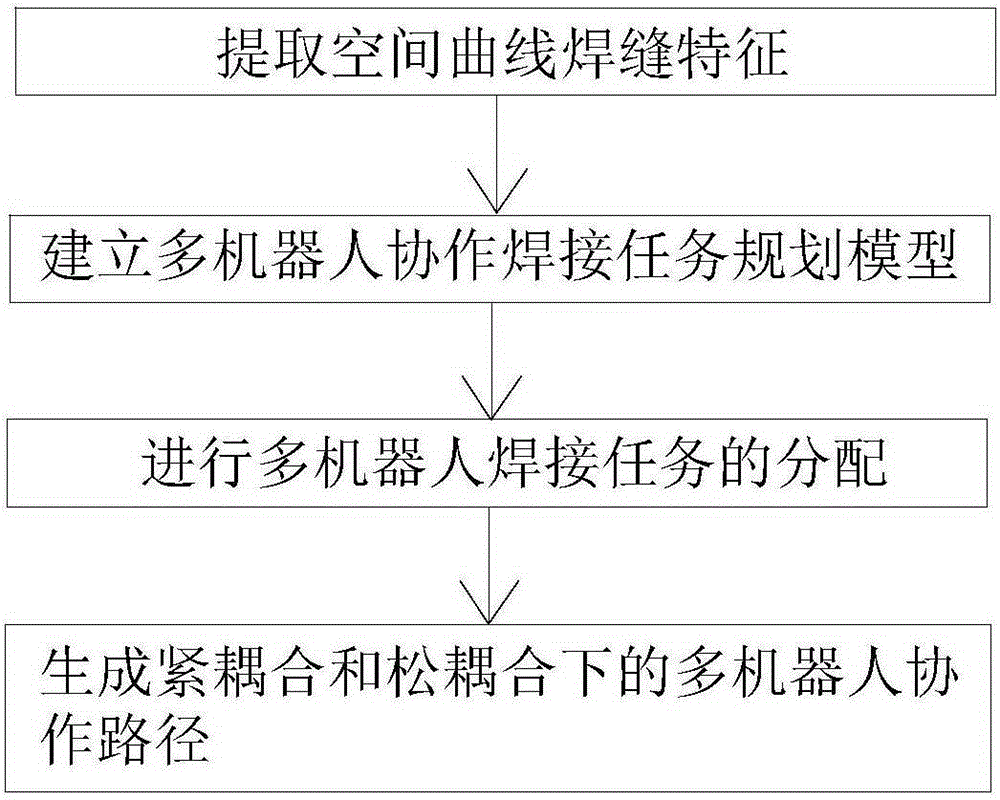

[0076] Such as figure 1 As shown, a method for generating a multi-robot collaborative welding path based on task decoupling in an embodiment of the present invention includes the following steps:

[0077] Step 1: According to the workpiece model to be welded, using the method of combining chord tolerance and minimum step size, the weld seam is discretized by taking points at non-equidistant distances, and the characteristics of the space curve weld seam are extracted;

[0078] The second step: based on the space curve weld features extracted in the first step, establish the optimization goals of minimizing the working time and optimizing the working time balance, as well as the constraints of simultaneous welding constraints, safety time constraints and dynamics / kinematics constraints Conditional multi-robot collaborative welding task planning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com