Dryer for high-density fiberboards

A high-density fiberboard and dryer technology, applied in dryers, drying, progressive dryers, etc., can solve the problems of long time, easy to be limited by weather, increase the installation space of production lines, etc., to reduce the length , the effect of high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

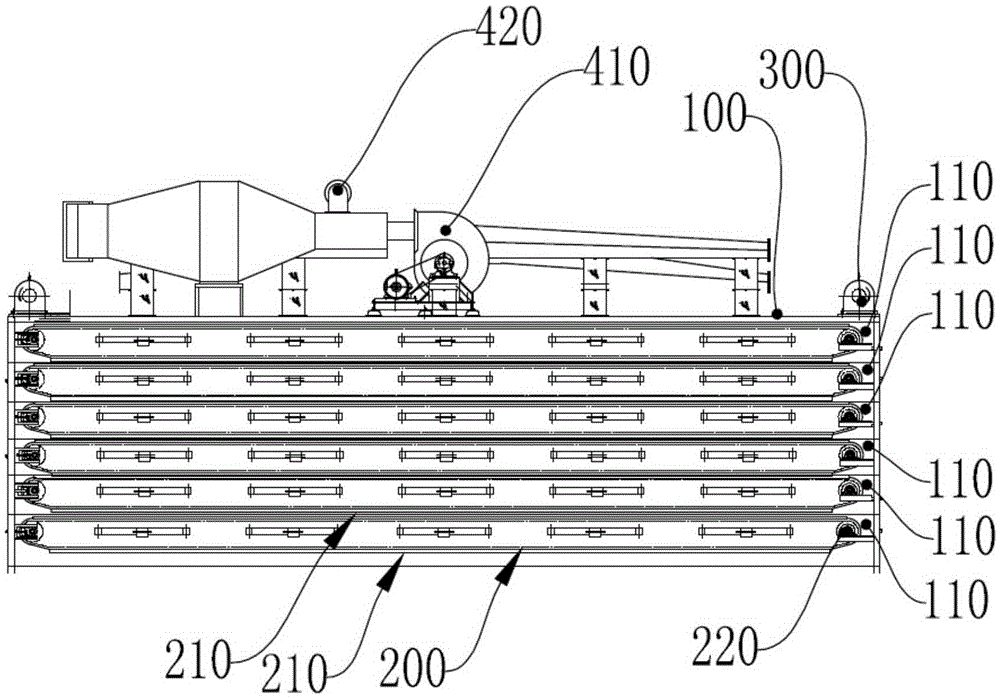

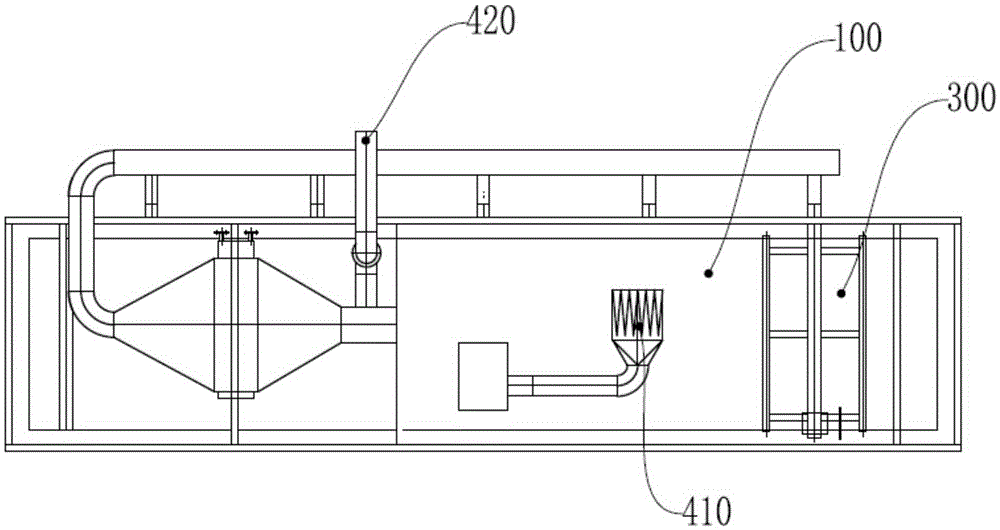

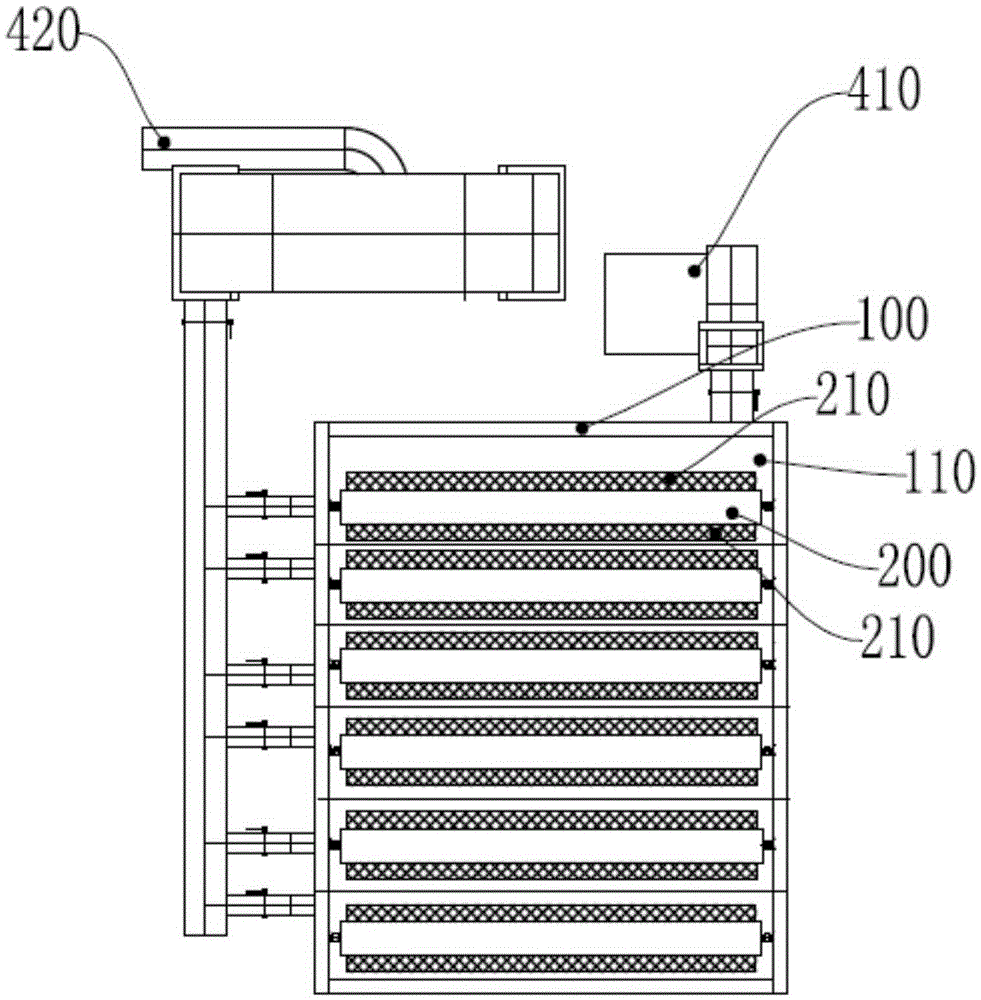

[0023] like Figure 1-3 As shown, a high-density fiberboard dryer includes a drying room 100. The drying room 100 is provided with six layers of drying rooms 110, and the drying rooms 110 are stacked up and down. One end of the drying room 110 There is a feed port, and one end is provided with a discharge port; each layer of drying chamber 110 is provided with a conveyor belt 200 and a driving device 300 for driving the conveyor belt 200 to rotate, and the conveyor belt 200 is provided with a fixed drying chamber for drying. The mesh bag 210 ; the conveyor belt 200 drives the mesh bag 210 to rotate in the drying chamber 110 ; the drying chamber 100 is provided with a heating device for heating the drying chamber 110 .

[0024] The dryer is provided with an air convection device, and the air convect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com