Double-channel cold and heat source haze purifying and heating tower

A cold and heat source, dual-channel technology, applied in refrigeration and liquefaction, heat pumps, refrigerators, etc., can solve problems such as pollution, solution moisture content drift, etc., and achieve the effect of safety, reliability and economic guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

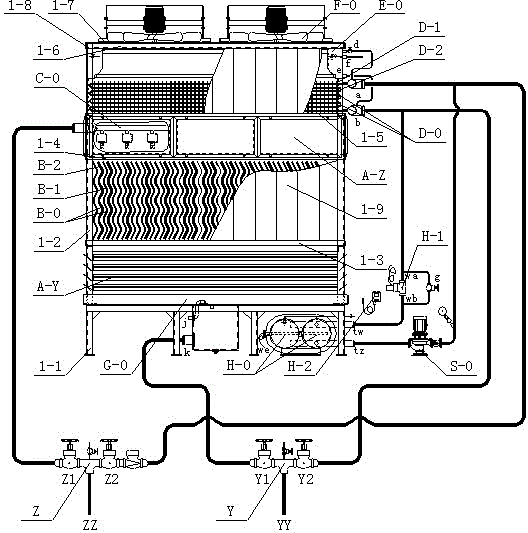

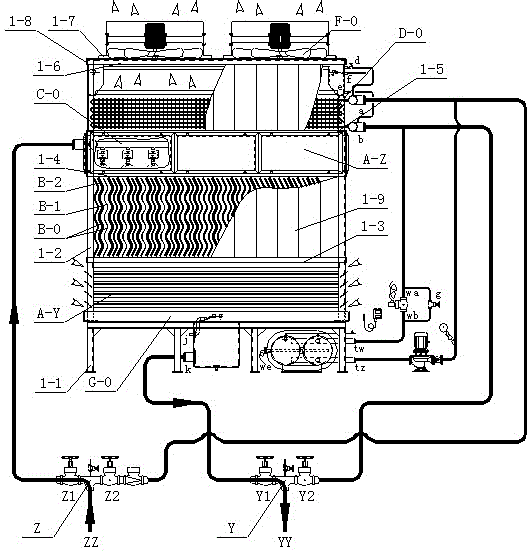

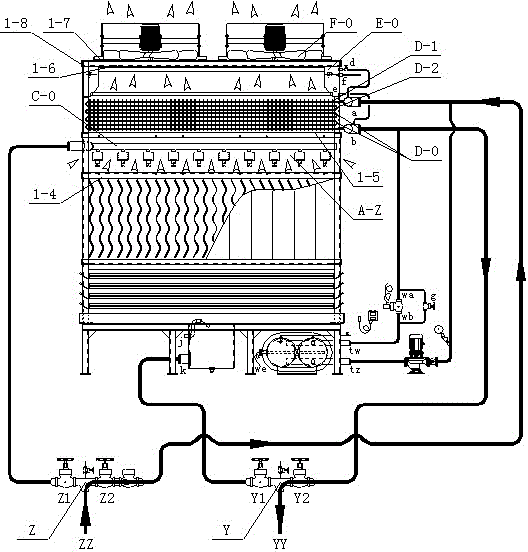

[0022] The following is combined with the accompanying drawings: figure 1 , figure 2 , image 3 , Figure 4 The schematic diagram of the principle of the "dual-channel cold and heat source smog purification and heat extraction tower" of the present invention will be further explained.

[0023] Referring to the accompanying drawings, this embodiment includes a bottom-inlet liquid film evaporation cold purification system 1; an upper-inlet finned tube haze suction and heat extraction system 2;

[0024] Note: The hollow arrows in the figure indicate the direction of air flow, and the solid arrows indicate the direction of circulating medium, liquid and water circulation.

[0025] The bottom-inlet liquid-film evaporative cold purification system 1 includes water-cooled air-inlet grid A-Y; water-cooled liquid-film heat exchange layer B-0, liquid-film substrate B-1, and liquid-film wind chamber B-2; water-cooled Water spray device C-0; guide valve group Y; guide valve group Z; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com