Long-neck gas fuel spray nozzle capable of being adjusted in multiple angles

A gas fuel, multi-angle technology, applied in combustion chambers, combustion methods, combustion equipment and other directions, can solve the problems of accidents, gaseous fuel systems prone to explosion, total time increase, etc., to achieve simple connection, reduce the incidence of gas leakage failures , the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with embodiment.

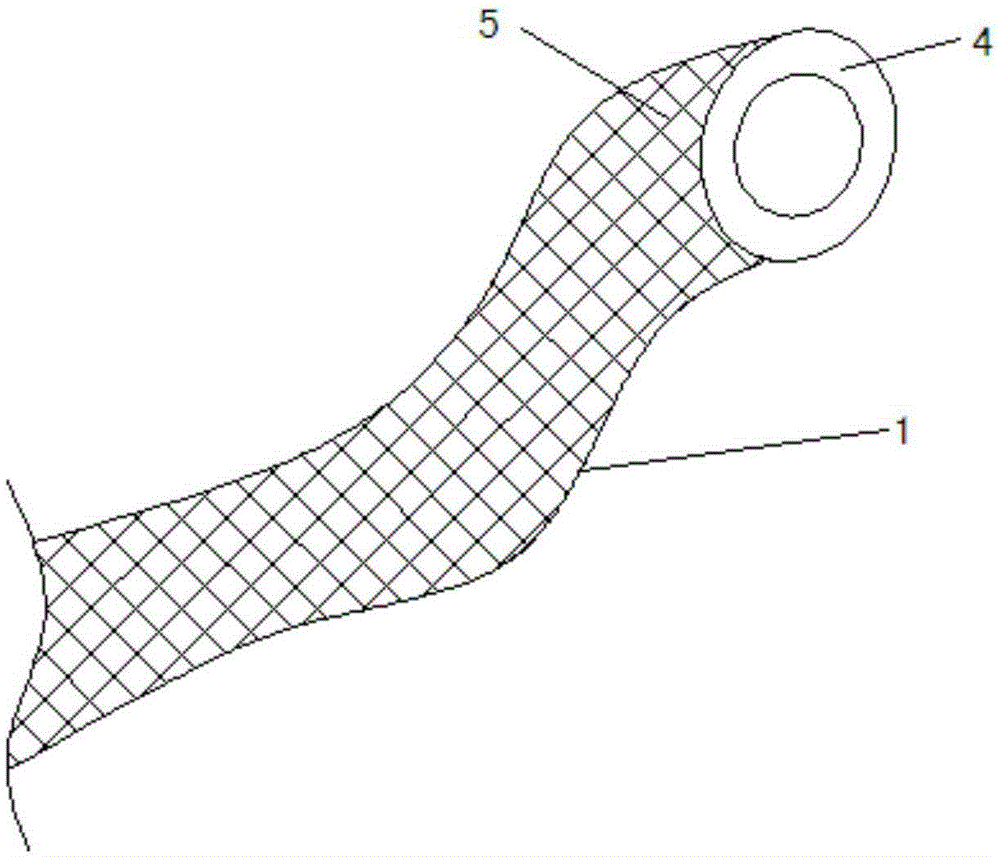

[0015] according to Figure 1 ~ Figure 2 As shown, a multi-angle adjustable long-necked gas fuel nozzle includes a metal hose 1, one end of the metal hose 1 is fixed to the pipe joint 2, and the other end is fixed to the gas nozzle 3; the metal hose 1 includes a bellows 4 , The bellows 4 is covered with a layer of metal mesh 5, the metal hose 1 can work under a certain pressure and temperature range, can be bent at any angle, and has a small thermal expansion.

[0016] The metal hose 1 is inserted into the gas nozzle 3 and welded to prevent the gas leakage failure of the fuel system in the flow channel.

[0017] The wall thickness of the bellows 4 is 0.3-0.5mm, and the material is 1Cr18Ni9Ti.

[0018] The metal mesh surface 5 is composed of wire weaving, and the material is 1Cr18Ni9Ti. The metal mesh surface 5 is fixedly connected with the end of the bellows 4 to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com