A lighting fixing module for a colored metal model and a manufacturing method thereof

A color metal, fixed module technology, applied in the direction of light source fixation, fixed lighting device, light guide of lighting system, etc., can solve the problems of increasing energy consumption, unable to meet the model surface, increasing manufacturing cost, etc., to improve the grade and increase the appearance. Authenticity, the effect of reducing its own energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

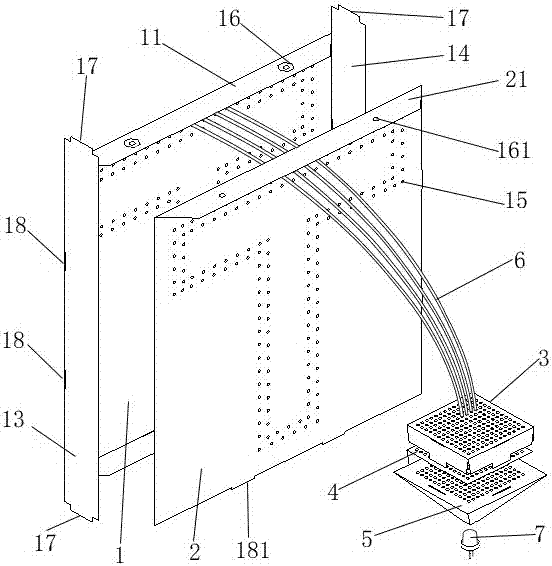

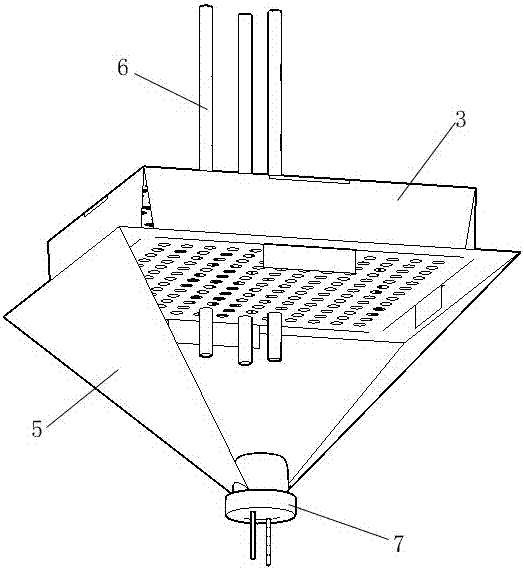

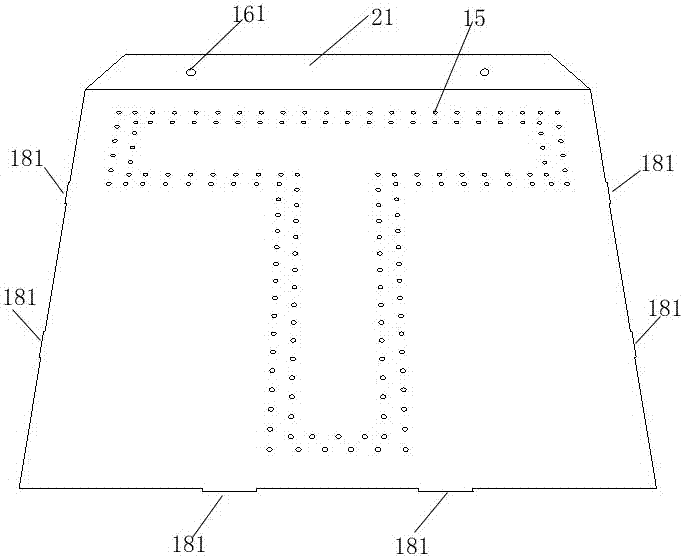

[0035] Embodiment 1: A lighting fixing module.

[0036] Such as Figure 1 to Figure 7 As shown, it includes an optical fiber holder A, an optical fiber holder B, a reflector 5, an optical fiber 6 and an LED light source 7. The optical fiber holder A includes a clip AA1 and a clip AB2, and the clip AA1 and the clip AB2 are provided with Optical fiber hole 15, clip AA1 is provided with upper flap 11, lower flap 12, left flap 13 and right flap 14, upper flap is provided with nut positioning groove plus screw hole 16, lower flap 12, left flap 13 and The right flange 14 is provided with a card slot E18, the clip AB2 is provided with an upper flange 21, and the upper flange 21 is provided with a screw hole 161 matching the nut positioning groove and the screw hole 16 provided on the upper flange 11 of the clip AA1, The lower part and the left and right edges are provided with buckles E181 that match the card slots E18 of the lower fold 12, left fold 13 and right fold 14 of the clip...

Embodiment 2

[0038] Embodiment 2: The production of a luminous metal cube model using a lighting fixture module.

[0039] (1) Use 3DS MAX software to import the sorted 3D digital model of the cube. The cube is 200mm long, 200mm wide, and 200mm high.

[0040] (2) Select the cube 3D digital model, right-click, select "Convert to Editable Poly", convert it to Editable Poly, select "Polygon" in the "Editable Poly" modifier in the upper right corner of the window, and select "Polygon" in the cube Press the left button on the surface of the 3D digital model, select the face where the light needs to be installed and execute the "separate" command. make it a separate object.

[0041] (3) Click the "Create" button in the upper right corner of the window, select "Graphics", "Spline"; then right-click on the "Snap Switch" at the top of the window, and set "Top Tick "Multiple" and "Surface"; then close the settings, click "Snap Switch" to enable the capture function; use the "Line" tool of "Spline...

Embodiment 3

[0070] Embodiment 3: Fabrication of a luminous metal triangular prism model using a lighting fixture module.

[0071] (1) Use 3DS MAX software to import the sorted 3D digital model of the triangular prism. The height of the triangular prism is 200mm, the top and bottom are regular triangles, and the side length is 200mm.

[0072] (2) Select the 3D digital model of the triangular prism, right-click, and select "Convert to Editable Poly", convert it to an editable polygon, and then select "Polygon" in the "Editable Poly" modifier in the upper right corner of the window, in the Click the left button on the surface of the 3D digital model of the triangular prism, select the face where the light needs to be installed and execute the "Separate" command. make it a separate object.

[0073] (3) Click the "Create" button in the upper right corner of the window, select "Graphics", "Spline"; then right-click on the "Snap Switch" at the top of the window, and set "Top Tick "Many" and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com