A kind of multifunctional metal roof and its construction method

A technology of metal roofing and construction method, applied in the direction of roofing, roof covering, roofing using flat/curved panels, etc., can solve the problems of increasing roof weight, dry roof with water storage, and high requirements for building load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

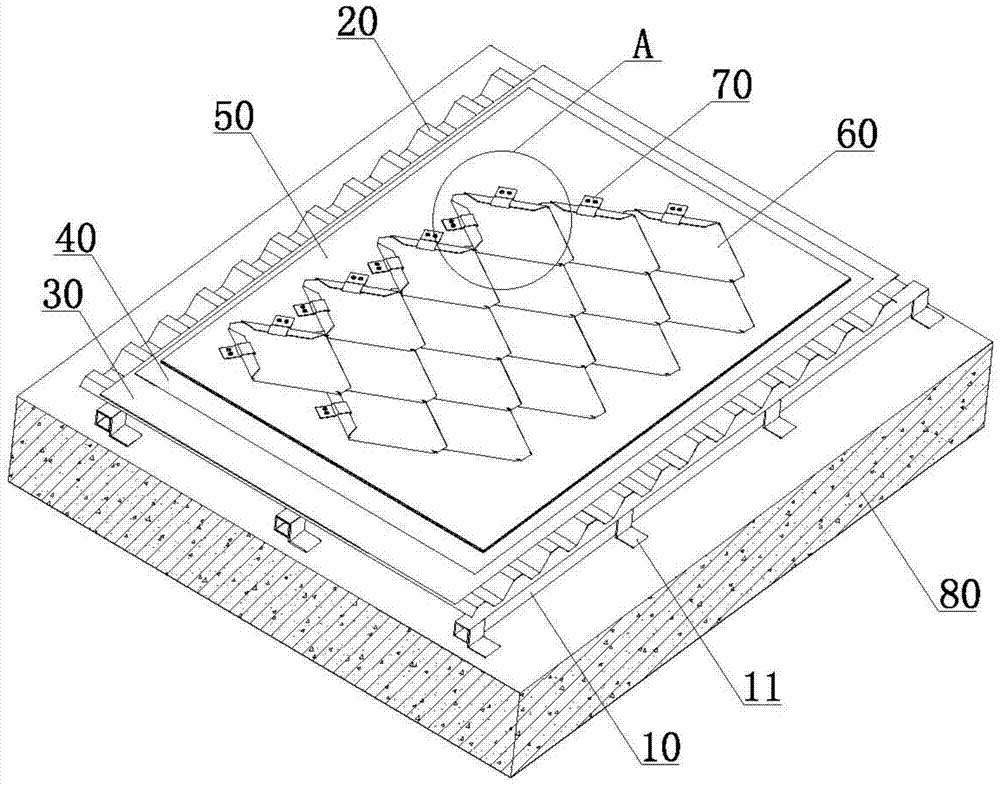

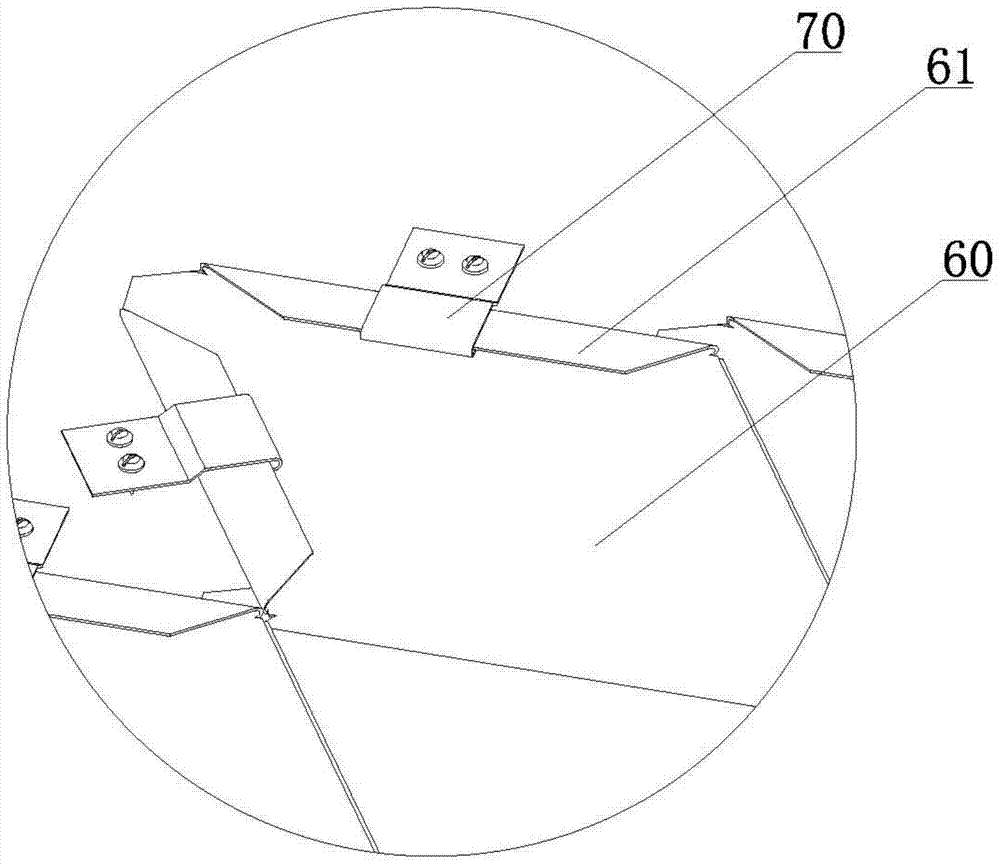

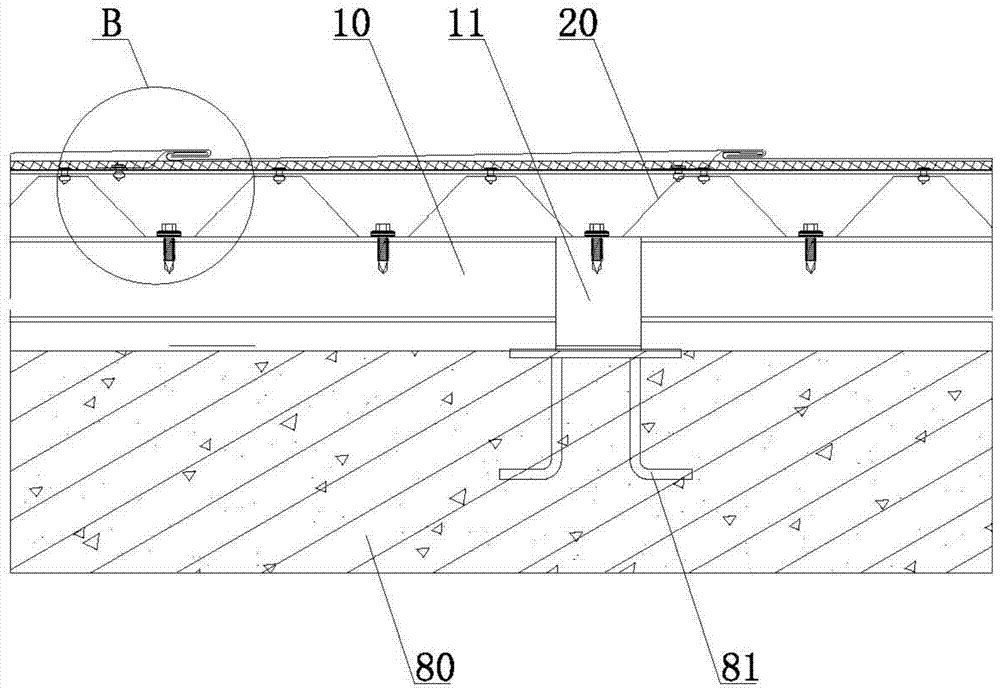

[0039] like Figure 1 to Figure 7 As shown, a multifunctional metal roof provided by the embodiment of the present invention includes several roof purlins 10 installed on the top surface of the building and profiled steel plates 20 fixed on the top surface of the roof purlins 10, which also includes leveling steel plates 30 , waterproof coiled material 40, ventilation and noise-reducing wire mesh 50 and several aluminum-magnesium-manganese alloy gussets 60, the leveling steel plate 30 is fixed on the top surface of the profiled steel plate 20, the waterproof coiled material 40 is fixed on the top surface of the leveling steel plate 30, several The aluminum-magnesium-manganese alloy gusset 60 is stacked and fixed on the top surface of the waterproof coiled material 40 , and the ventilation and noise-reducing wire mesh 50 is laid between the waterproof coiled material 40 and the aluminum-magnesium-manganese alloy gusseted plate 60 . Specifically, the waterproof coiled material 4...

Embodiment 2

[0044] like Figure 1 to Figure 7 As shown, the construction method of a multifunctional metal roof provided in this embodiment includes the following construction steps:

[0045] a. Take out several roof purlins 10, and separate and install several roof purlins 10 on the top surface of the building; among them, the roof purlins 10 can adopt □150*100*5.0mm galvanized steel square pass, □according to the needs of the installation location 100*100*4.0mm galvanized steel square pass or □50*50*3.0mm galvanized steel square pass, etc.;

[0046] b. Take out the profiled steel plate 20, lay the profiled steel plate 20 on the top surface of several purlins and fix it with several purlins, wherein, the profiled steel plate 20 can be 0.6mm thick VP125 profiled steel plate;

[0047] c. Take out the leveling steel plate 30, lay the leveling steel plate 30 on the top surface of the profiled steel plate 20 and fix it with the profiled steel plate 20; wherein, the leveling steel plate 30 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com