Method for preparing konjac glucomannan gel through direct current

A technology of konjac glucomannan and direct current is applied in electrolytic coatings, electrophoretic plating, coating and other directions to achieve the effects of cost saving, easy control and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

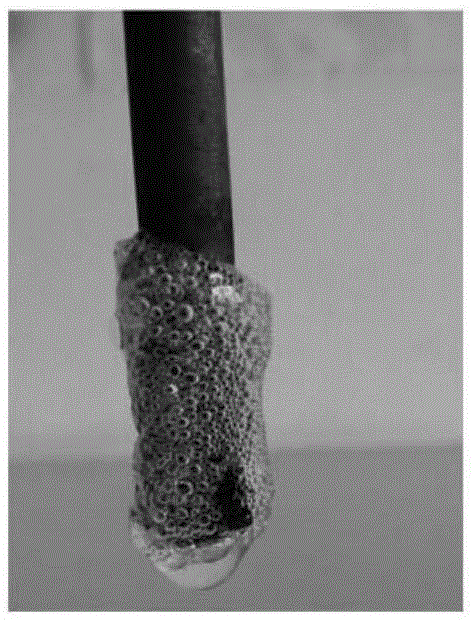

[0024] Accurately weigh konjac flying powder, disperse in distilled water at room temperature, and prepare a 0.3% aqueous sol, and add sodium tungstate dihydrate to make the mass concentration 0.1%. Insert the electrode into the hydrosol containing sodium tungstate, and pass through 20V direct current for 3 minutes to get konjac glucomannan gel on the positive electrode, such as figure 1 As shown, the konjac glucomannan gel covers the electrode surface, and the gel is rich in air bubbles and elastic.

Embodiment 2

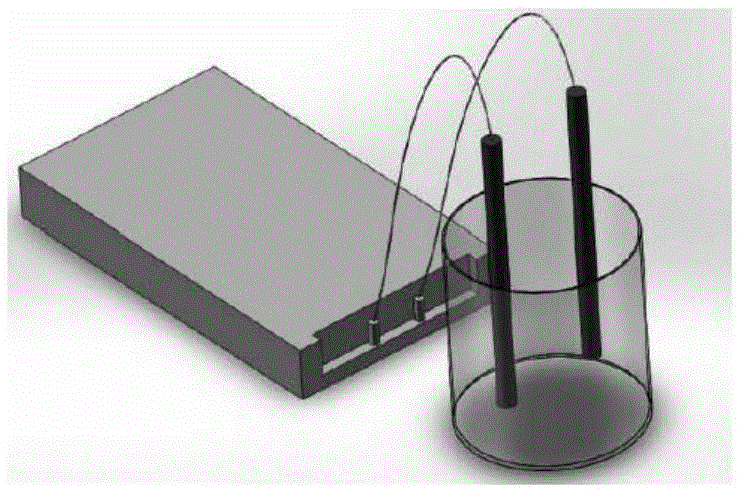

[0026] Accurately weigh konjac flying powder, disperse in distilled water at room temperature, and prepare a 1.1% aqueous sol, and add sodium tungstate dihydrate to make the mass concentration 0.5%. Insert the electrode into the hydrosol containing sodium tungstate, the schematic diagram of the device is shown in figure 2 , the hydrosol is packed in a beaker, the current is provided by an external power supply, and a direct current of 40V is applied for 12 minutes to obtain konjac glucomannan gel on the positive electrode.

Embodiment 3

[0028] Accurately weigh konjac flying powder, disperse in distilled water at room temperature, and prepare a 0.5% aqueous sol, and add sodium tungstate dihydrate to make the mass concentration 0.3%. Insert the electrode into the hydrosol containing sodium tungstate, and apply a direct current of 25V for 9 minutes to obtain konjac glucomannan gel on the positive electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com