A stainless steel cleaning agent with bactericidal properties

A cleaning agent, stainless steel technology, applied in the field of stainless steel cleaning agent, can solve problems such as inability to apply, achieve good removal effect, simple use method, and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

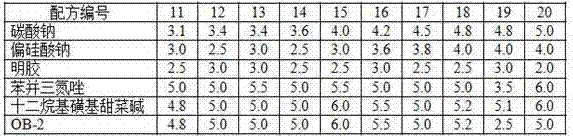

[0032] Embodiment formula is as follows:

[0033]

[0034]

[0035] The preparation method of above-mentioned embodiment is:

[0036] Mix sodium carbonate, sodium metasilicate and gelatin raw materials according to the ratio and stir them evenly at 40°C, then let them stand for 1 hour, then add other raw materials and stir them at a constant speed for 2 hours at room temperature, and use a concentration of 0.1% while stirring Sulfuric acid solution and / or 10% sodium metasilicate solution to adjust the pH value to 7-7.5 to obtain the desired stainless steel cleaning agent.

[0037] The stirring temperature depends on the formula. If the dissolution rate of the raw materials is slow, the stirring temperature can be increased appropriately, but the stirring temperature should not exceed 60°C. When the cleaning agent foams after stirring, the standing time can be extended appropriately, and then adjusted pH value.

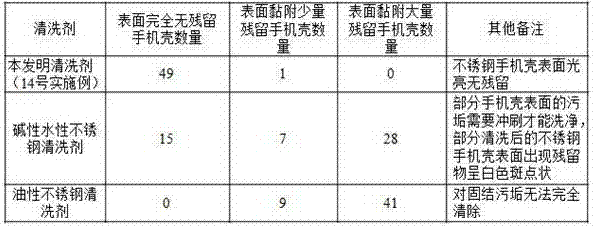

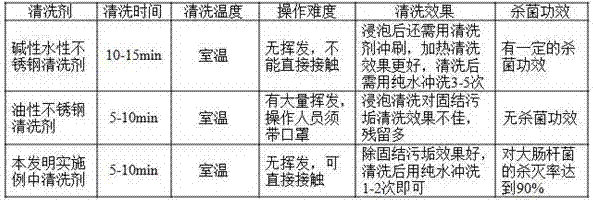

[0038] Cleaning effect comparison:

[0039] The commerci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com