Manganese and iron separation and recovery method of manganese-poor iron ore

A separation and recovery, manganese-poor technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of poor adjustment of reduction conditions, long roasting time, etc., to reduce acid consumption, fast reaction speed, reduce acid consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

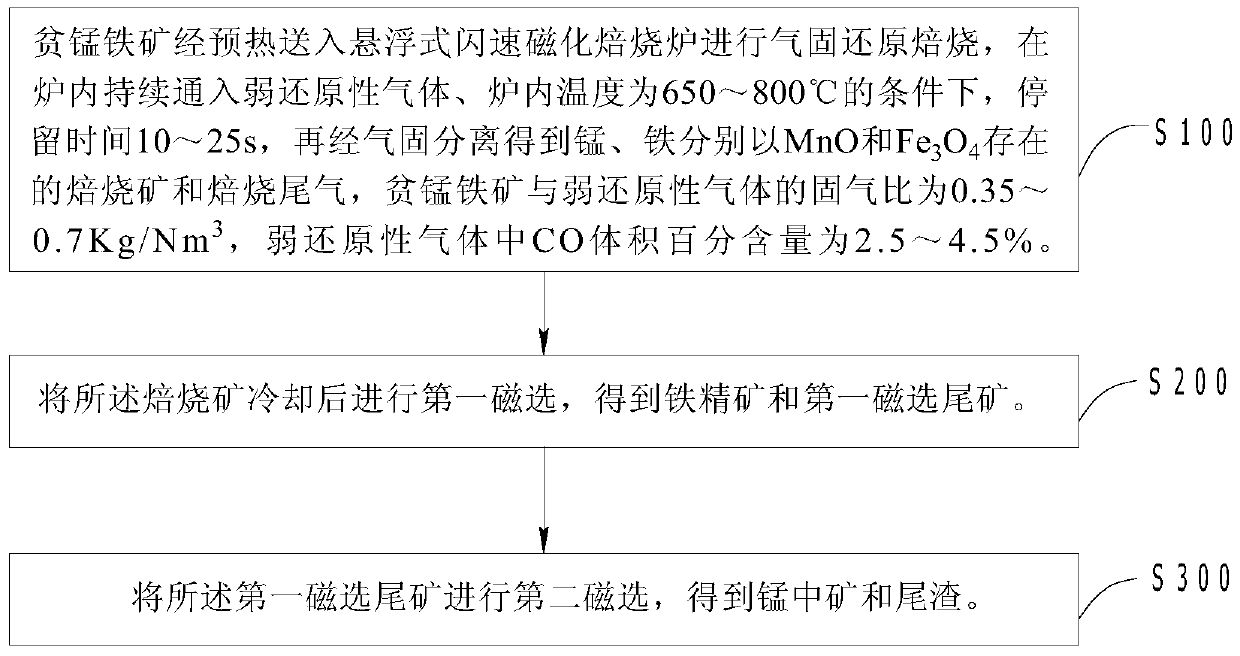

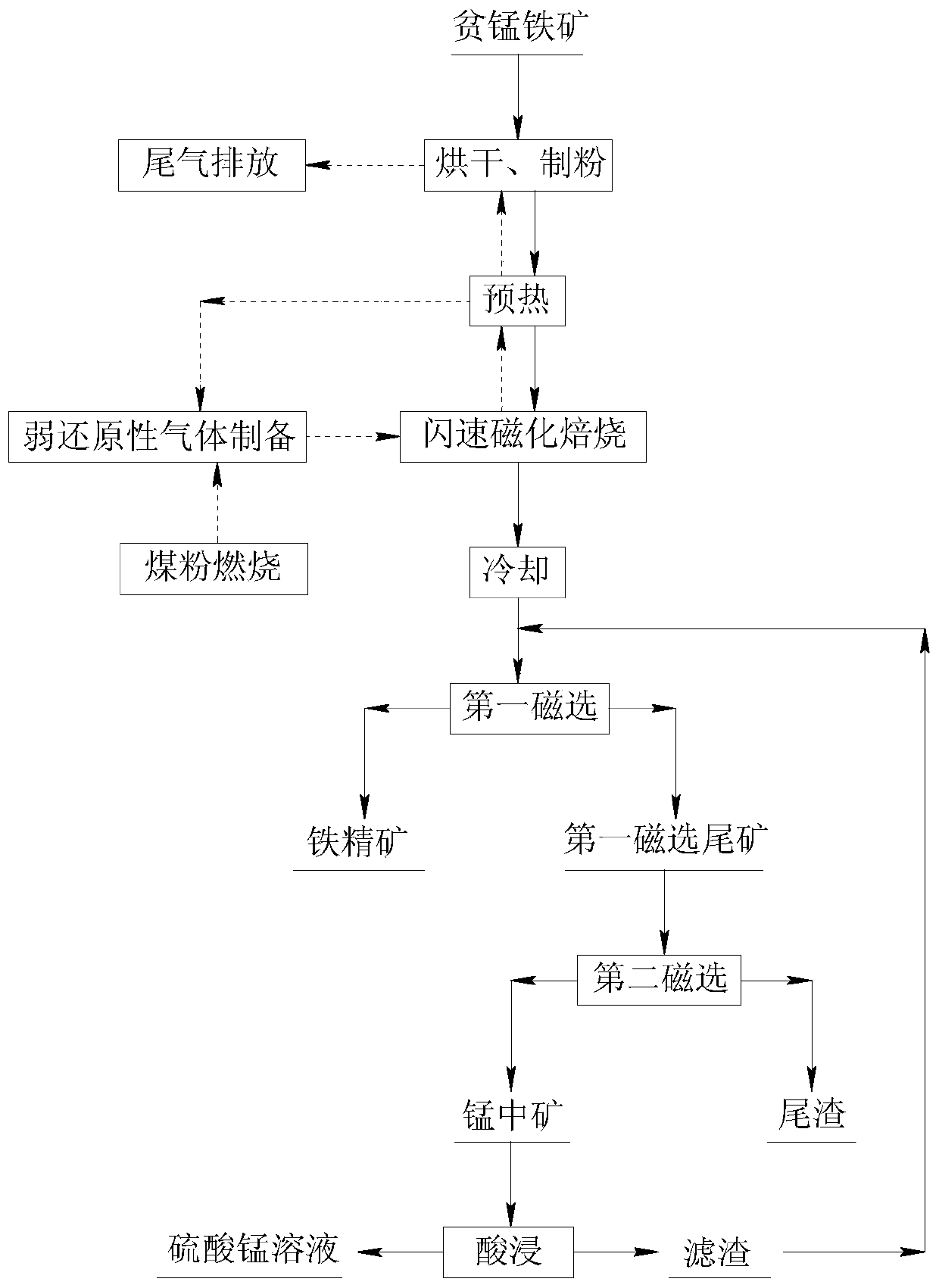

[0067] refer to figure 2 , in the manganese-poor iron ore processed, the grade of manganese is 19%, and the grade of total iron is 35%. The above-mentioned manganese-poor iron ore is dried and ground in an air-swept ball mill until the particle size is -200 mesh, accounting for 75%. The above-mentioned dried and ground mineral powder enters the four-stage cyclone preheater for preheating. The preheating uses the roasting tail gas after the suspension flash magnetization roasting as the preheating gas. The gas temperature after the first stage preheating is 250°C. The gas temperature after the second stage preheating is 400°C, the gas temperature after the third stage preheating is 550°C, and the gas temperature after the fourth stage preheating is 650°C; the fourth stage preheating time is 10s. The volume percent content of CO in the preheated tail gas produced after four-stage preheating is 0.1%, O 2Volume percentage 3 , the residence time in the furnace is 10s, after the r...

Embodiment 2

[0075] refer to figure 2 , in the processed manganese iron ore, the grade of manganese is 13%, and the grade of total iron is 45%. The above manganese iron ore is dried and ground in an air-swept ball mill until the particle size is -200 mesh, accounting for 80%. The above-mentioned dried and ground fine ore enters the three-stage cyclone preheater for preheating. The preheating uses the roasting tail gas after the suspension flash magnetization roasting as the preheating gas. The gas temperature after the first stage preheating is 350°C. The gas temperature after the second stage preheating is 550°C, and the gas temperature after the third stage preheating is 650°C; the third stage preheating time is 50s. The volume percentage of CO in the preheated tail gas produced after the three-stage preheating is 1%, O 2 Volume percentage 3 , the residence time in the furnace is 25s. After the reaction is completed, gas-solid separation is carried out to obtain a temperature of 750 ° ...

Embodiment 3

[0083] refer to figure 2 , a poor manganese iron ore in southern Hunan, in which the grade of manganese is 11.89%, and the grade of total iron is 41.51%. The dried and ground mineral powder is preheated by the primary or secondary cyclone preheater. The preheating adopts the suspension type gas-solid reduction roasting exhaust gas, and the preheating time is 30s; the preheating exhaust gas after preheating The volume percentage of CO is 0.6%; the preheated ore powder enters the suspension flash magnetization roasting furnace for gas-solid reduction roasting, and the weak reducing gas with a CO volume percentage of 3.6% is continuously fed into the furnace and Maintain the temperature in the furnace at 650°C, and control the solid-gas ratio of manganese iron ore and weakly reducing gas in the furnace to 0.55Kg / Nm 3 , the residence time in the furnace is 20s, after the reaction is completed, the gas-solid separation is carried out, and the temperature is 600 ℃, manganese and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com