Oxygen-bearing coal-bed gas low-temperature concentration method and device for implementing method

A low-temperature enrichment, coalbed methane technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of high energy consumption, complex process flow, etc., and achieve the effect of low energy consumption, low energy consumption, and a small number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

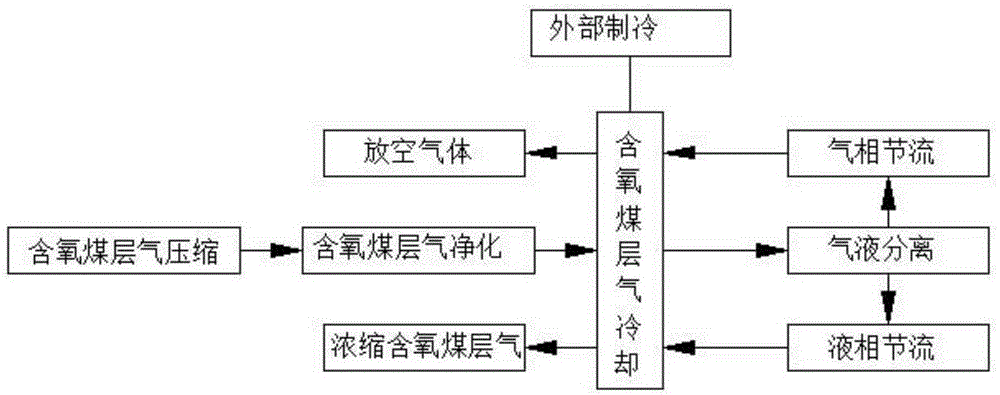

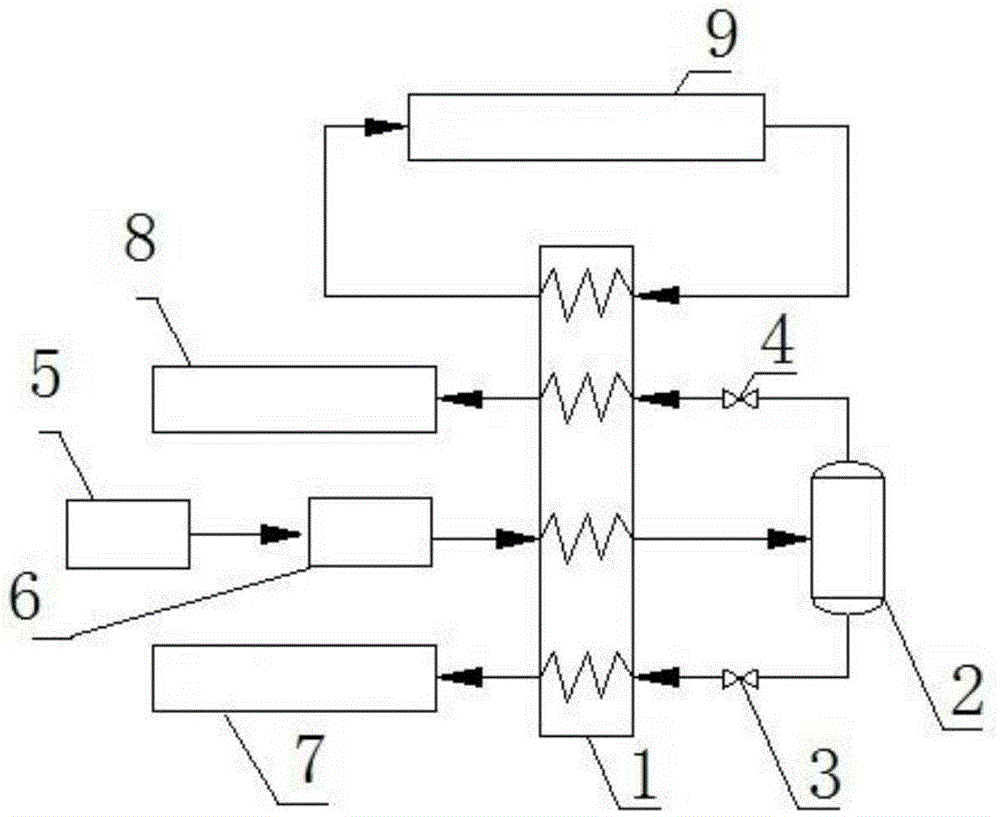

[0030] The present embodiment is 35% with methane content, and nitrogen content is 50%, and oxygen content is about 15% oxygen-containing coalbed methane (also contains trace hydrogen sulfide, carbon dioxide and water), then according to figure 1 The steps shown and figure 2 Described equipment carries out low-temperature concentration, and specific steps are as follows:

[0031] Pressurize the oxygen-containing coalbed methane to 0.2MPa at 40°C in the compressor 5, then purify the oxygen-containing coalbed methane in the purifier 6 until the hydrogen sulfide content is less than 5ppm, the carbon dioxide content is less than 100ppm, and the water content is less than 0.1ppm; Pass the purified gas into the heat exchanger 1 to cool down to -169°C, then pass the cooled oxygen-containing coalbed gas into the gas-liquid separator 2 for gas-liquid separation; the separated liquid passes through the liquid throttle valve 3 The liquid phase throttling is obtained, the obtained liqui...

Embodiment 2

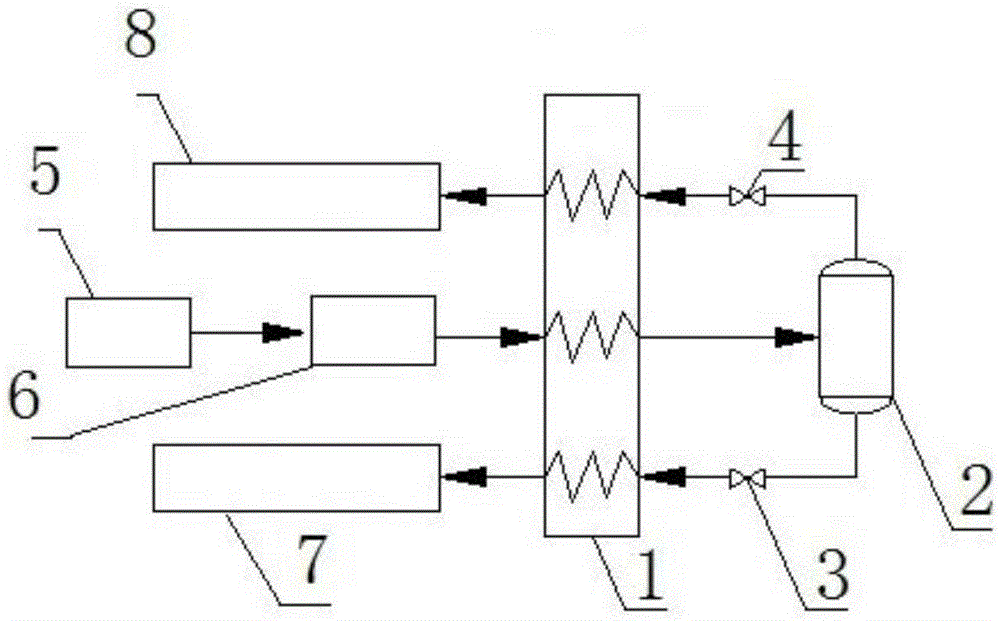

[0035] In this implementation, the methane content is 60%, the nitrogen content is 31.667%, and the oxygen-containing coalbed methane with an oxygen content of about 8.333% (also contains traces of hydrogen sulfide, carbon dioxide and water), and then according to figure 1 The steps shown and image 3 Described equipment carries out low-temperature concentration, and specific steps are as follows:

[0036] Pressurize the oxygen-containing coalbed methane to 0.2MPa at 40°C in the compressor 5, then purify the oxygen-containing coalbed methane in the purifier 6 until the hydrogen sulfide content is less than 5ppm, the carbon dioxide content is less than 100ppm, and the water content is less than 0.1ppm; The purified coal gas is passed into the heat exchanger 1 to cool to a temperature of -169.5°C, and then the cooled oxygen-containing coalbed gas is passed into the gas-liquid separator 2 for gas-liquid separation; the separated liquid is obtained through the liquid throttle valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com