Method for preparing cefonicid dibenzyl ethylenediamine salt

A technology for dibenzyl ethylene diamine salt and dibenzyl ethylene diamine, which is applied in the field of preparing cefonicil dibenzyl ethylene diamine salt, can solve the problem of low utilization rate of equipment, poor quality and low yield and other problems, to achieve the effect of less impurities, lower production costs and higher yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

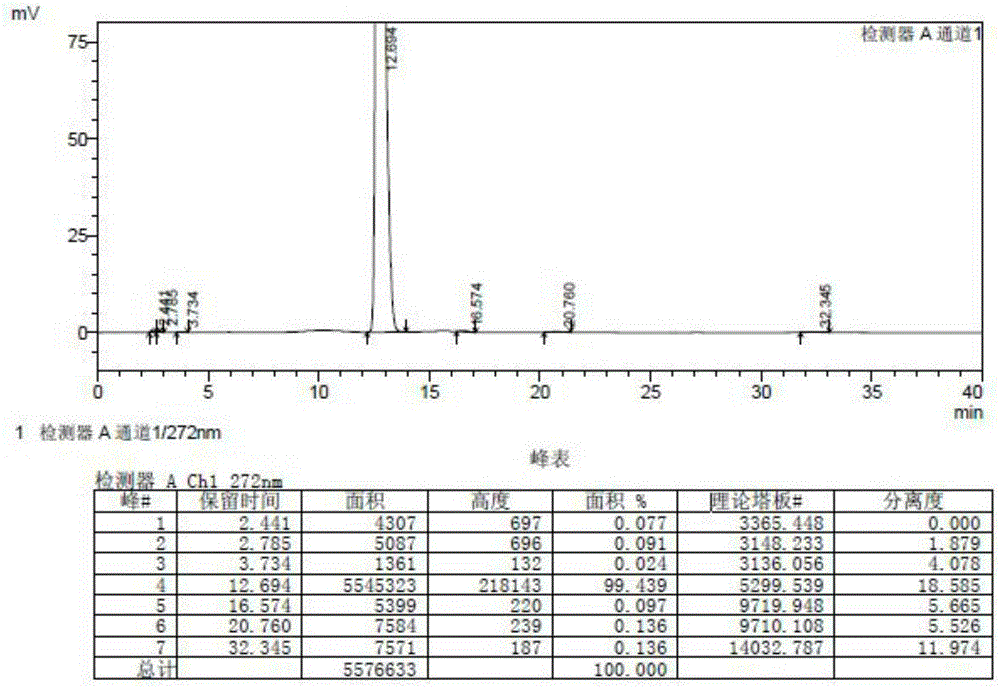

Embodiment 1

[0054] A. Acylation reaction: Add 100kg of raw material I in 600L of purified water, then add dilute ammonia water and stir until it is completely dissolved, cool down in -7°C water, and add 8g of tetrabutylammonium bromide after the temperature of the reaction system drops to 3°C. Feed 53kg of raw material II, and at the same time feed dilute ammonia water to control the pH of the reaction system to be 6.0-8.0, and the reaction time is 0.5 hours to obtain an aqueous solution of formylcefocinic acid, and the reaction temperature is controlled at 0-5°C during the whole process;

[0055] B. Deformylation reaction: Add 25L of 37% (mass fraction) concentrated hydrochloric acid to the aqueous solution of formylcefocinic acid obtained in step A, the solution is warmed up to 35°C, and the hydrolysis reaction is carried out for 3 hours to obtain the aqueous solution of cefuroxime acid; Then lower the temperature to 25°C, add 10kg of activated carbon for decolorization for 30 minutes, f...

Embodiment 2

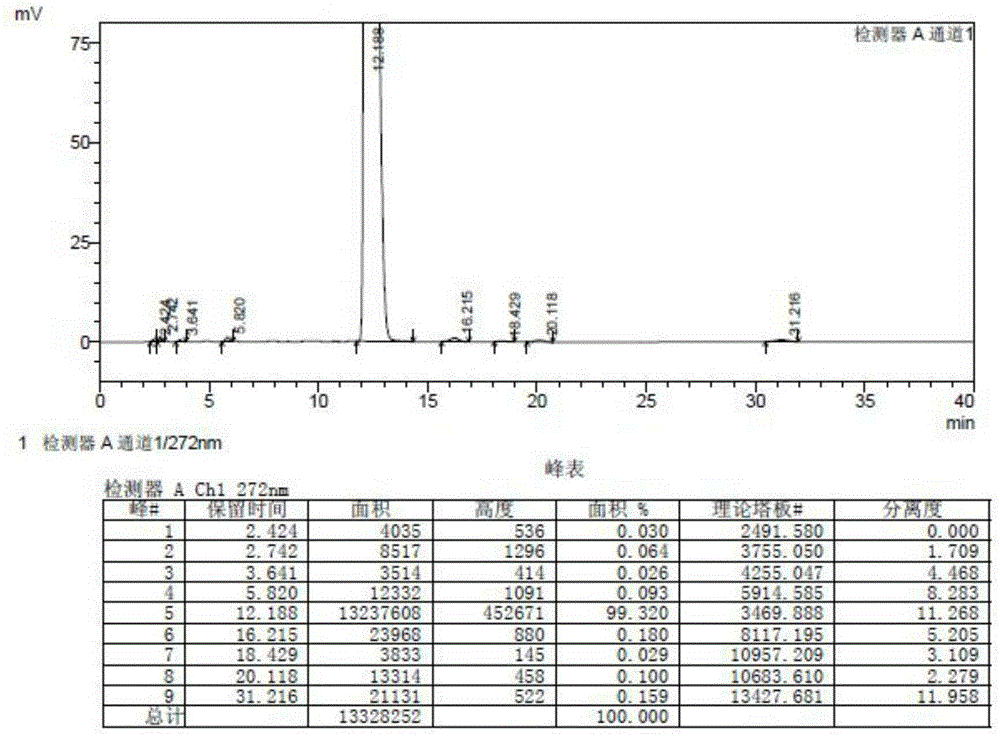

[0058] A. Acylation reaction: In 600L of purified water, add 100kg of raw material I, then add dilute ammonia water and stir until it is completely dissolved, cool down in -7°C water, and add 340g of tetrabutylammonium chloride after the temperature of the reaction system drops to 4°C. Feed 53 kg of raw material II, and at the same time feed dilute ammonia water to control the pH to 6.0-8.0, and the reaction time is 2 hours to obtain formylcefocinic acid aqueous solution, and the reaction temperature is controlled at 0-5°C during the whole process;

[0059] B. Deformylation reaction: Add 34L of 85% (mass fraction) phosphoric acid to the aqueous solution of formyl cefocinic acid obtained in step A, and the solution is warmed up to 25° C., and undergoes hydrolysis for 9 hours to obtain an aqueous solution of cefocinic acid; Decolorize 10kg of activated carbon for 30min, filter, wash with a small amount of water, and combine the filtrate;

[0060] C. Salt-forming reaction: add 13...

Embodiment 3

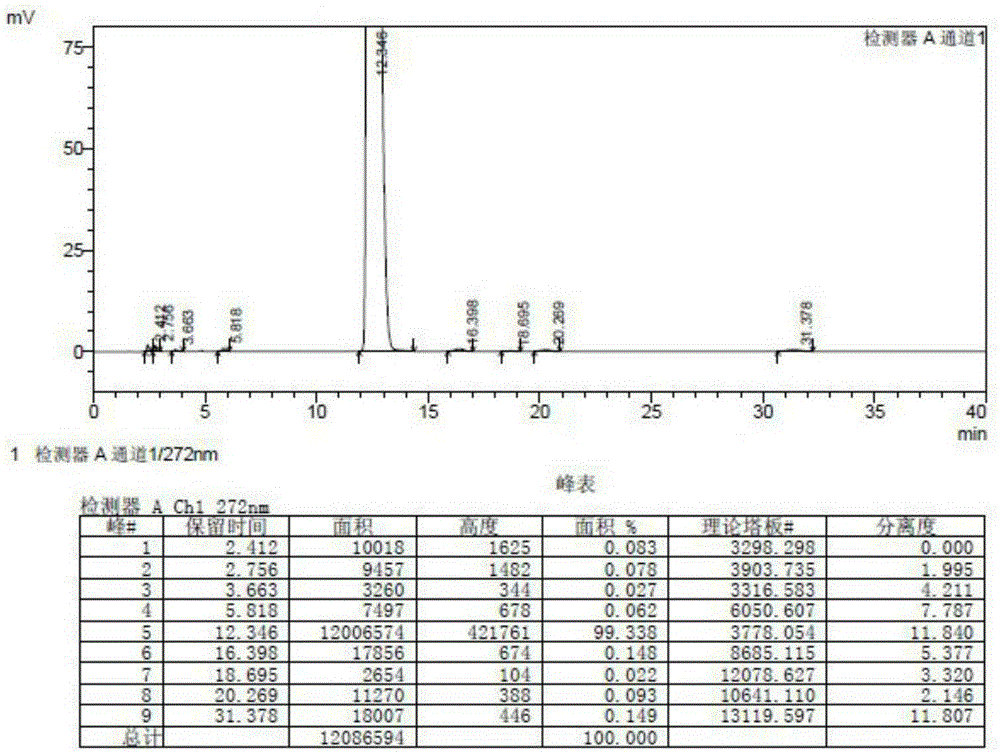

[0062] A. Acylation reaction: In 600L of purified water, add 100k of raw material I, then add dilute ammonia and stir until it is completely dissolved, cool down in -7°C water, add 50g of TEBA after the temperature of the reaction system drops to 0°C, and then add 53kg of raw material II, At the same time, dilute ammonia water was added to control the pH to 6.0-8.0, and the reaction time was 1 hour to obtain an aqueous solution of formylcefocinic acid, and the reaction temperature was controlled at 0-5°C during the whole process;

[0063] B. Deformylation reaction: add the mixed acid of 20L37% (mass fraction) concentrated hydrochloric acid and 10L85% (mass fraction) phosphoric acid in the aqueous solution of formyl cefocinic acid that step A obtains, solution is warming up to 30 ℃, hydrolysis reaction After 7 hours, an aqueous solution of cefocinic acid was obtained; 10 kg of activated carbon was added for decolorization for 30 min, filtered, washed with a small amount of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com