A kind of preparation method of sulfa-6-methoxypyrimidine

A technology of methoxypyrimidine and sodium methoxypyrimidine, which is applied in the field of preparation of sulfonamide-6-methoxypyrimidine, can solve the problems of skin corrosion, irritation of human mucous membranes, uncertainty, etc. Impurities, the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

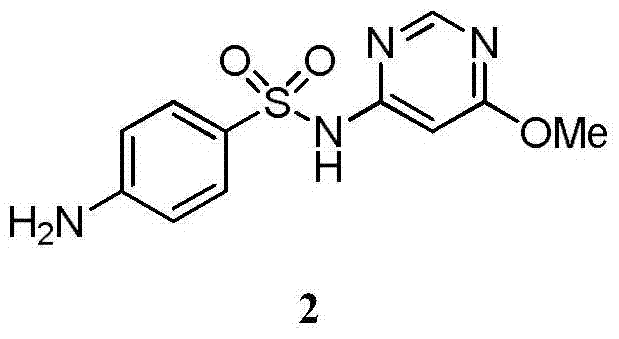

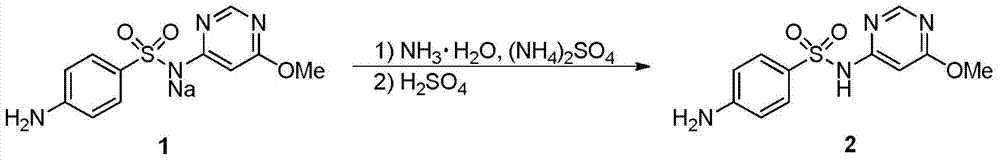

Image

Examples

Embodiment 1

[0016] Add 85.0 g of crude sulfa-6-methoxypyrimidine sodium, 400 ml of ultrapure water, and 3.5 g of activated carbon into a 1000 ml four-necked round-bottomed flask. The mixture is stirred at 40° C. for 30 minutes and then filtered while hot. The filtrate was transferred to a new 1000 ml four-neck round bottom flask, 5.5 ml of 25% ammonia water and 12.0 g of ammonium sulfate were added, and after distillation for 45 minutes at 60°C (vacuum degree was -0.076~-0.080MPa), the temperature was raised to 95°C , Distilled under the vacuum degree of -0.010~-0.012MPa until there is no obvious ammonia smell. After the distillation is over, add 5% sulfuric acid solution while it is hot until the pH of the reaction system is 5.8, cool down to 45°C and filter, wash the filter cake with ultrapure water and dry it at 85-90°C with a vacuum of -0.093--0.100MPa A white solid of sulfa-6-methoxypyrimidine was obtained.

Embodiment 2

[0018] Add 85.0 g of crude sulfa-6-methoxypyrimidine sodium, 400 ml of ultrapure water, and 3.5 g of activated carbon into a 1000 ml four-necked round-bottomed flask. The mixture is stirred at 40° C. for 30 minutes and then filtered while hot. The filtrate was transferred to a new 1000 ml four-neck round bottom flask, 5.5 ml of 25% ammonia water and 12.0 g of ammonium sulfate were added, and after distillation for 45 minutes at 60°C (vacuum degree was -0.076~-0.080MPa), the temperature was raised to 95°C , Distilled under the vacuum degree of -0.010~-0.012MPa until there is no obvious ammonia smell. After the distillation is over, add 5% sulfuric acid solution while it is hot until the pH of the reaction system is 6.0, cool down to 45°C and filter, wash the filter cake with ultra-pure water and dry it at 85-90°C with a vacuum of -0.093--0.100MPa A white solid of sulfa-6-methoxypyrimidine was obtained.

Embodiment 3

[0020] Add 85.0 g of crude sulfa-6-methoxypyrimidine sodium, 400 ml of ultrapure water, and 3.5 g of activated carbon into a 1000 ml four-necked round-bottomed flask. The mixture is stirred at 40° C. for 30 minutes and then filtered while hot. The filtrate was transferred to a new 1000 ml four-neck round bottom flask, 5.5 ml of 25% ammonia water and 12.0 g of ammonium sulfate were added, and after distillation for 45 minutes at 60°C (vacuum degree was -0.076~-0.080MPa), the temperature was raised to 95°C , Distilled under the vacuum degree of -0.010~-0.012MPa until there is no obvious ammonia smell. After the distillation is over, add 5% sulfuric acid solution while it is hot until the pH of the reaction system is 6.1, cool down to 45°C and filter, wash the filter cake with ultrapure water and dry it at 85-90°C with a vacuum of -0.093--0.100MPa A white solid of sulfa-6-methoxypyrimidine was obtained.

[0021] Repeat the experimental steps described in Example 1 above, changin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com