A method for denitrification phosphorus removal through anaerobic/nitrification/anoxic/nitrification process

A denitrification dephosphorization and nitrification reactor technology, applied in the direction of aerobic and anaerobic treatment, can solve the problems of sludge age contradiction between phosphorus accumulating bacteria and nitrifying bacteria, insufficient carbon source, high ammonia nitrogen in effluent, and improve the utilization rate , saving carbon and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

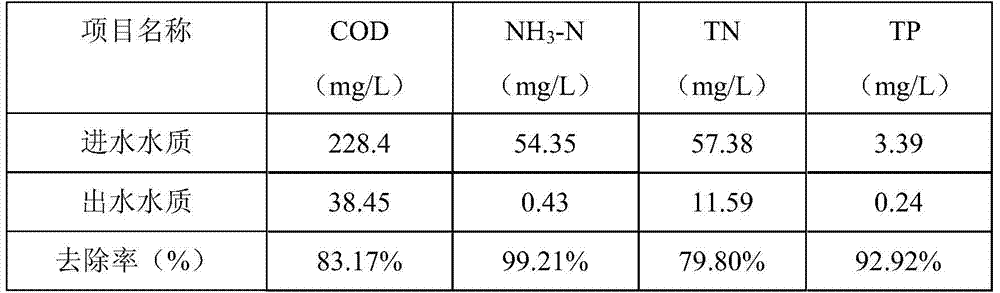

Examples

Embodiment approach

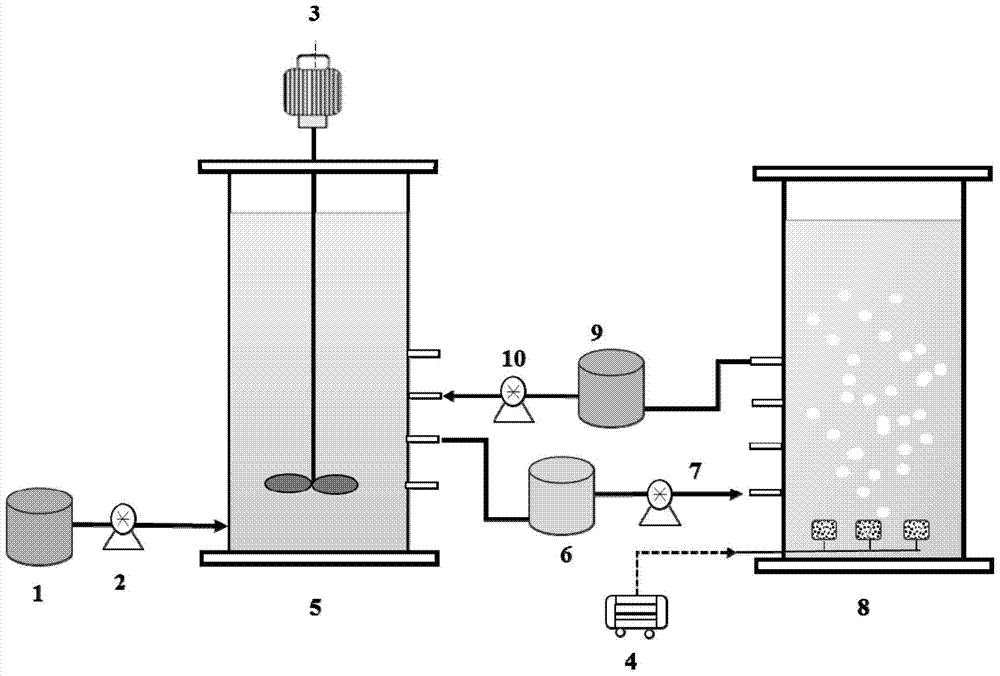

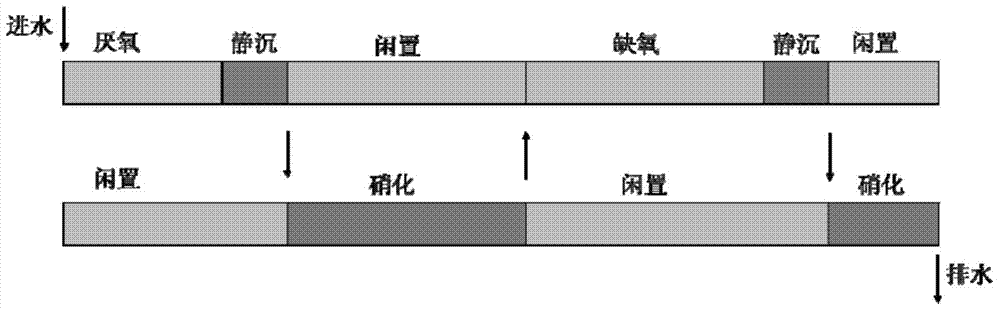

[0021] 1) The domestic sewage is passed through the raw water tank (1) through A 2 SBR inlet pump (2) into A 2 In the SBR reactor (5), after the water inflow is completed, the agitator (3) starts to stir, and the denitrifying phosphorus accumulating bacteria use the VFAs in the raw water to synthesize the internal carbon source PHA, and at the same time release the phosphate in the body to the outside. This stage controls A 2 DO≤0.02mg / L in SBR reactor, ORP=-150~-220mv, pH=6.5-7.3, water filling ratio 0.7, reaction time 1.5-2h. During this process, most of the COD is removed, and after the anaerobic stage reaction is completed, the water is drained quietly, and the supernatant rich in ammonia nitrogen enters the intermediate water tank (6).

[0022] 2) The N-SBR reactor (8) pumps the supernatant rich in ammonia nitrogen in the intermediate water tank (6) into the reactor through the N-SBR inlet pump (7), the water filling ratio is 0.7, and the air pump (4) turns on the aerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com