Automatic production method and production system of tableware injection molding packaging

An automatic production method and production system technology, applied in packaging, packaging sterilization, transportation and packaging, etc., can solve problems such as slow efficiency, low degree of automation, and high scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

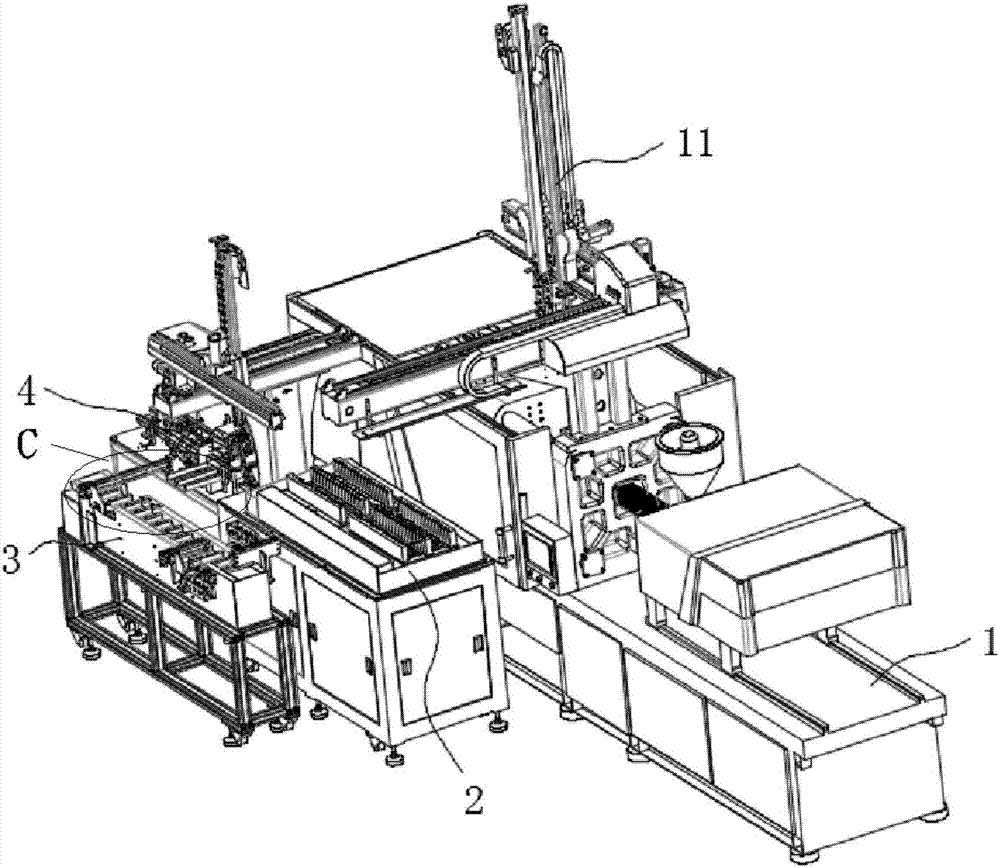

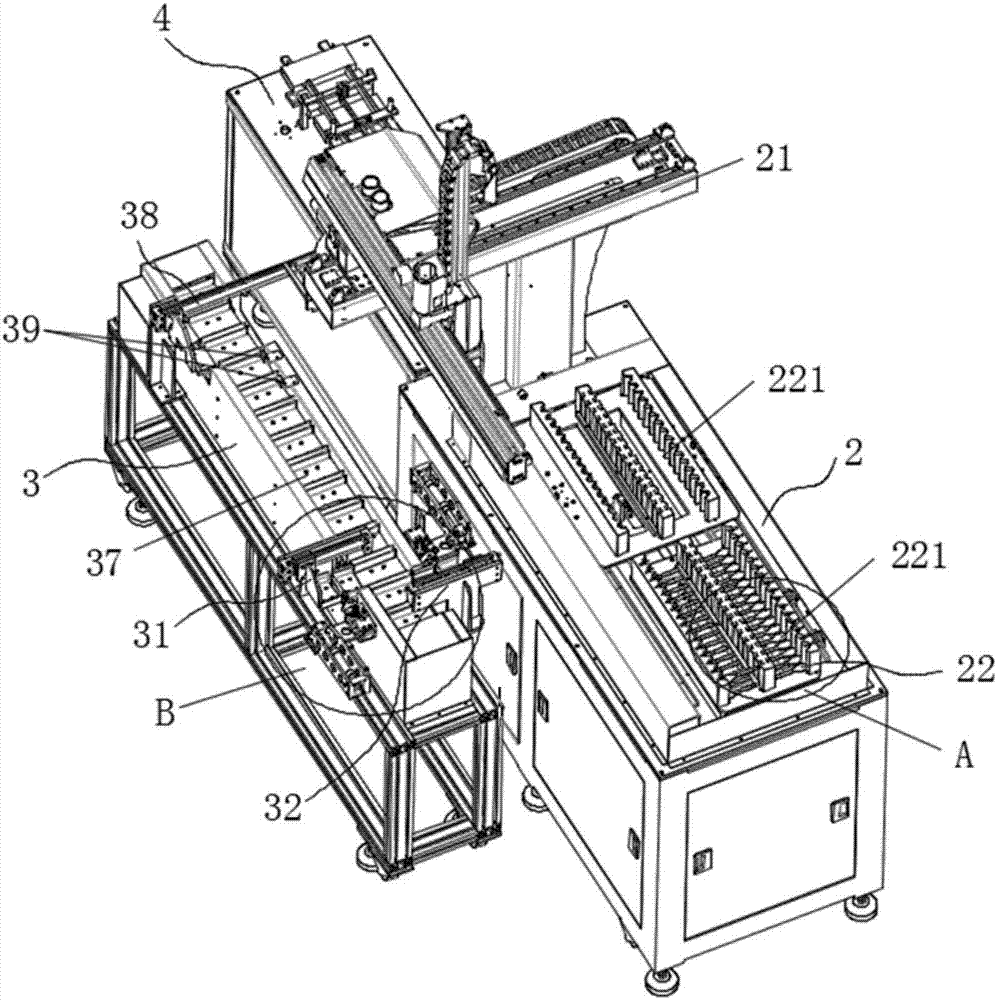

[0049] Examples, see Figure 1~6 , the automatic production method for tableware injection packaging provided in this embodiment, which includes an injection molding machine 1 and a take-out manipulator 11 on the injection molding machine 1, and a stacking and boxing device, which includes a stacking machine 2 and a box opening machine 4 And chain plate machine 3, and the displacement manipulator 21 that is arranged on stacking machine 2, described automatic production method comprises the following steps:

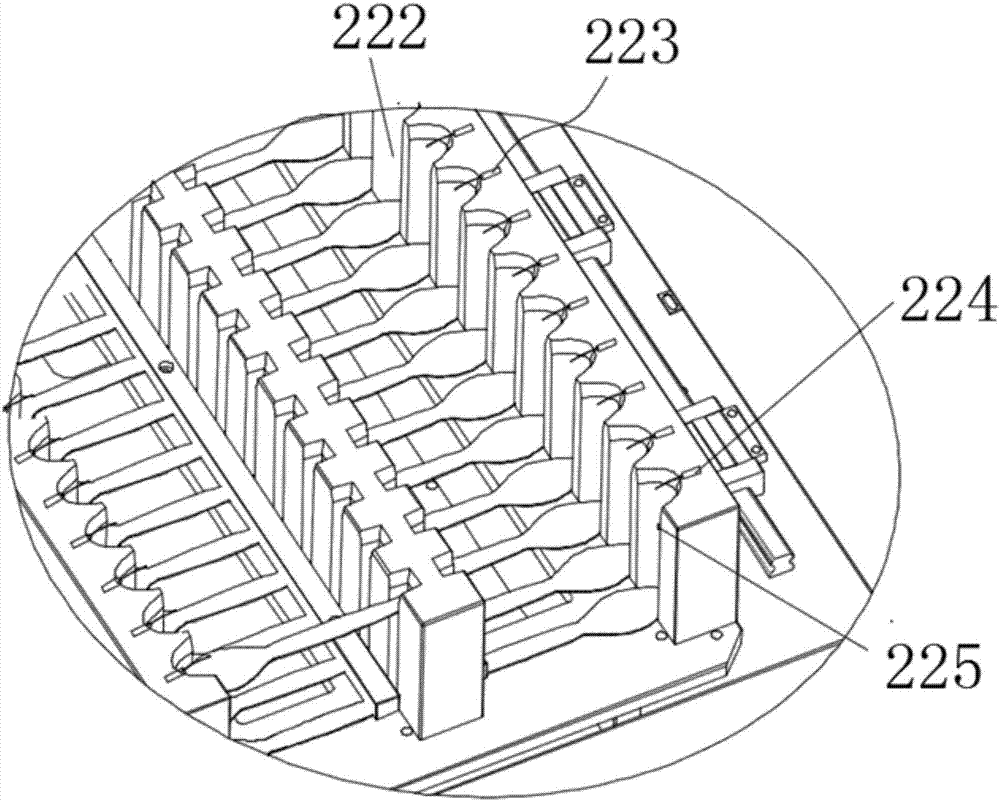

[0050] (1) Take out the manipulator 11 to take out the tableware injection molded parts in the injection molding machine 1, and place it in the special fixture 22 of the stacker 2; the special fixture 22 includes two finished product positioning plates 221, one of which is finished The positioning plate 221 is located below the take-out manipulator 11, and another finished product positioning plate 221 is located below the shifting manipulator 21; the finished product posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com