Emulsion explosive finished product cartridge bag automatic boxing equipment

A technology for automatic packing and emulsion explosives, which is applied in packaging and other directions, can solve the problems of deformation of the placement of finished emulsion explosives, affecting packing efficiency, and high equipment cost, achieving smooth stacking, high work efficiency, and convenient packing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

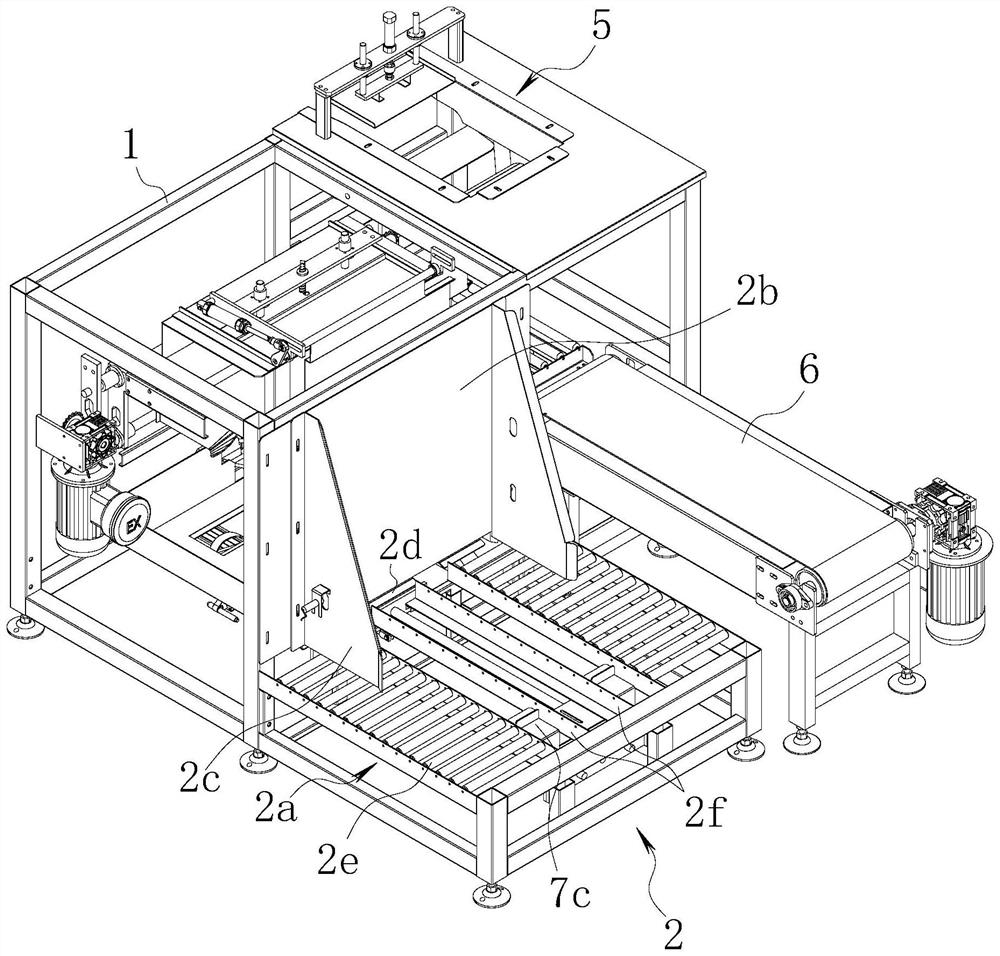

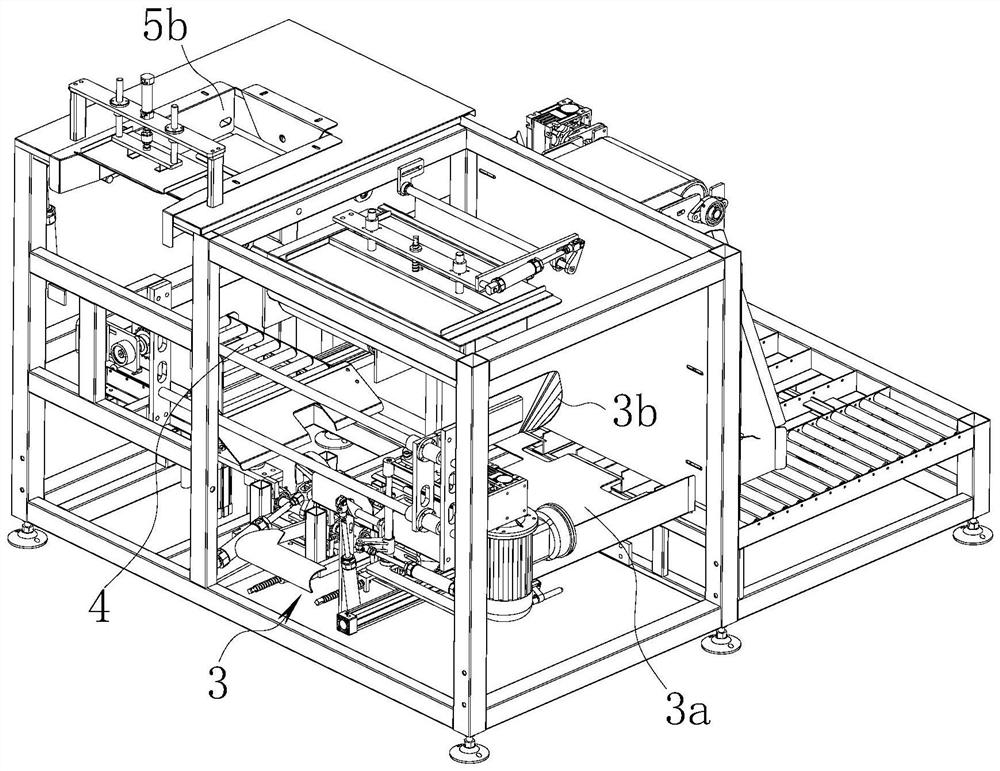

[0045] refer to figure 1 and figure 2 As shown, an automatic boxing device for finished emulsion explosives of the present invention includes a frame 1, and an automatic blank supply unit 2 is provided at one corner of the frame 1 . The box blank automatic supply unit 2 includes a stacking platform 2a arranged on the frame 1, a limiting partition 2b is vertically arranged at the discharge end of the stacking platform 2a, and a box and box are respectively arranged on both sides of the limiting partition 2b. The side guard plate 2c adapted to the billet is formed with an output port 2d for a single box blank output between the lower end surface of the limit partition 2b and the upper end surface of the stacking platform 2a, and the height of the output port 2d is 1.2 times the thickness of the box blank. -1.8 times, which can ensure that only one box blank passes through at a time.

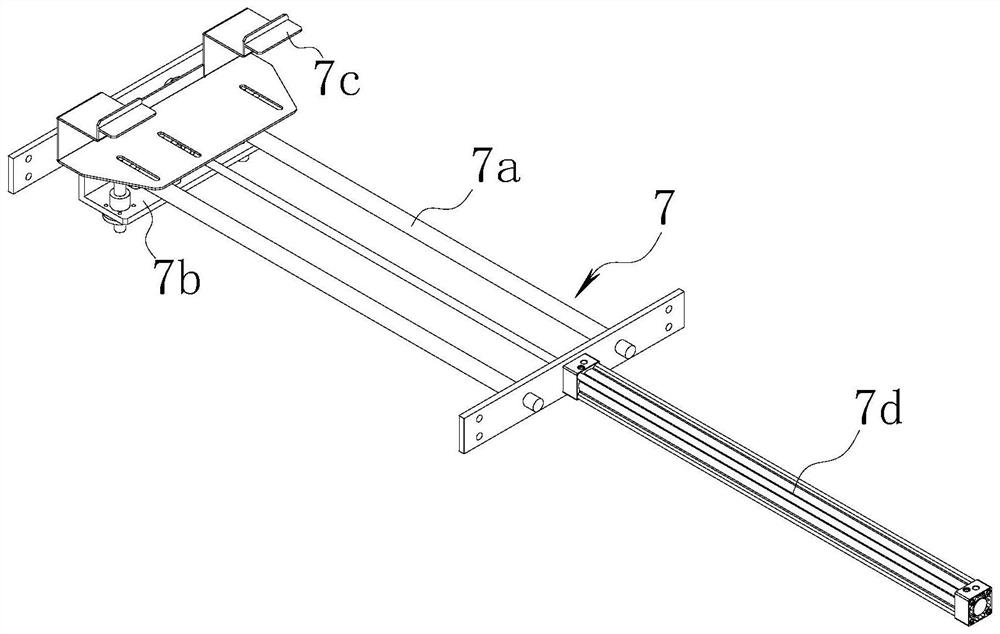

[0046] A scraper mechanism 7 is provided at the bottom of the stacking platform 2a, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com