Laminating and surface treatment equipment for high-strength polyester fiber netted sandwich cloth material

A polyester fiber and surface treatment technology, which is applied in the lamination and surface treatment equipment field of high-strength polyester fiber sandwich materials, to achieve the effect of convenient stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

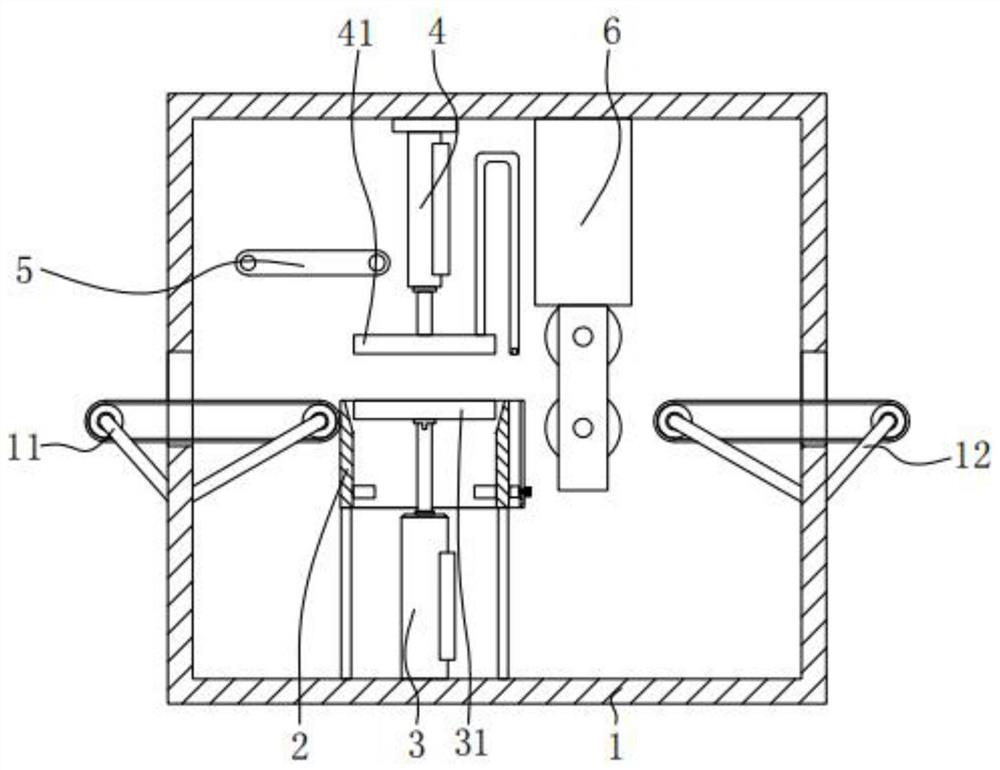

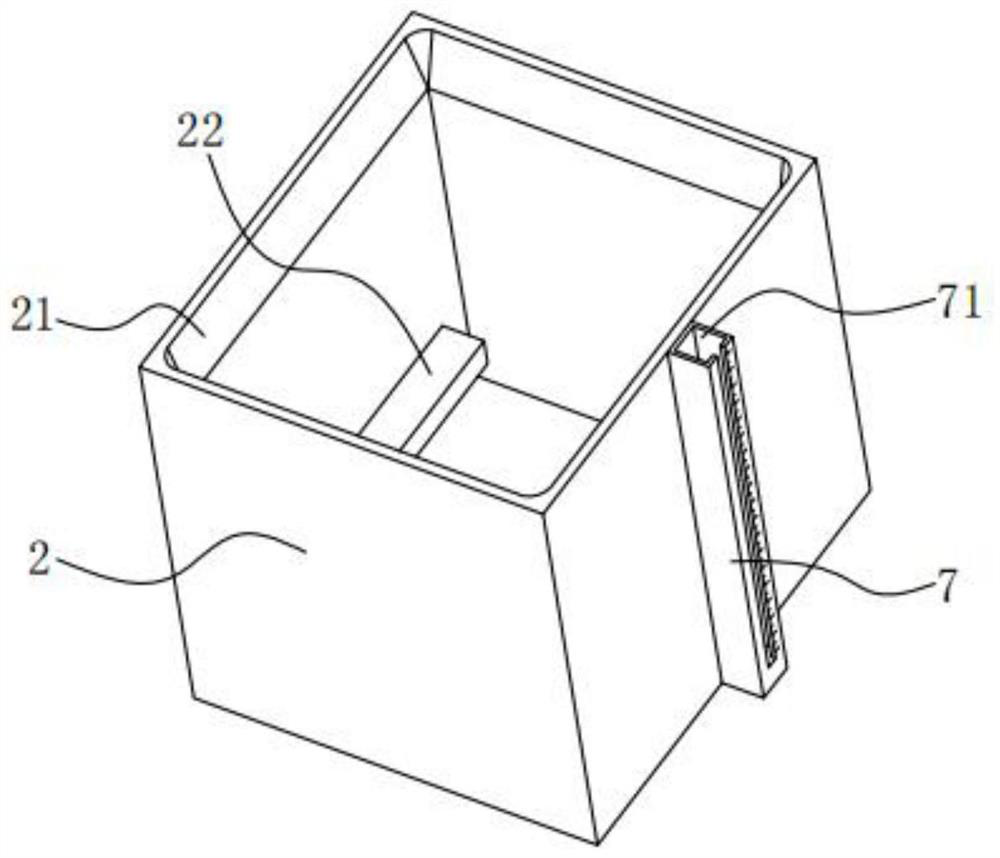

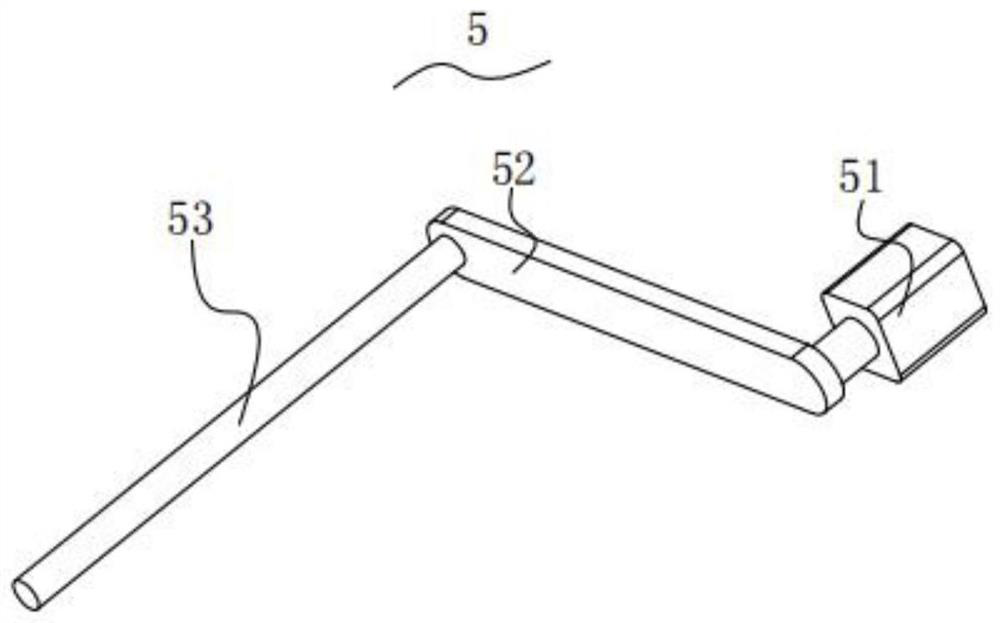

[0040] A lamination and surface treatment equipment for high-strength polyester fiber sandwich cloth material includes: a box body 1, on which a feeding mechanism 11 and a discharging mechanism 12 are respectively arranged; a forming frame 2, the forming The bottom of the frame 2 is fixedly installed on the inner wall of the box body 1, and the top of the forming frame 2 is provided with a buffer groove 21, and the inner wall of the forming frame 2 is fixedly connected with a limit baffle 22; the first lifting member 3, the The bottom of the first lifting member 3 is fixed on the inner wall of the box body 1, and the output end of the first lifting member 3 is fixedly connected with the first forming press plate 31; the second lifting member 4, the second lifting member 4 The top is fixedly installed on the inner wall of the box body 1, and the output end of the second lifting member 4 is fixedly connected with the second forming press plate 41; the feeding assembly 5 is instal...

Embodiment 2

[0064] The outer surface of the forming frame 2 is fixedly connected with a limit frame 7, and the limit frame 7 is provided with a limit chute 71, and the inner surface of the limit chute 71 is slidably connected with a limit slider 72. A locking screw shaft 73 is arranged on the position slider 72 , a linkage rod 8 is fixedly connected to the top of the second forming platen 41 , and a contact switch 81 is fixedly connected to the bottom of the linkage rod 8 .

[0065] By setting a limit slider 72 on the outside of the forming frame 2, the limit slider 72 can limit the lifting adjustment of the linkage rod 8, thereby controlling the degree of compression between the second forming press plate 41 and the first forming press plate 31 Limit the position to ensure the stability of the surface bonding of the raw material layer during the pressing and bonding process, and at the same time avoid excessive pressure that will affect the quality of the bonding to ensure the quality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com