A preparation method and application of gold-silica janus structure nanoparticles with high catalytic properties

A gold nanoparticle and nanoparticle technology, which is applied in the field of preparation and application of gold-silicon oxide Janus structure nanoparticles with high catalytic properties, can solve the problem of unsuitable industrial catalytic applications and reduce the catalytic activity of gold-silicon oxide Janus structure nanoparticles and other problems, to achieve the effect of excellent reusability, industrial application, and mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Embodiment 1: A gold-silicon oxide Janus structure nanoparticle with high catalytic properties described in this embodiment is irradiated by an ultraviolet lamp to an ethanol aqueous solution of gold-silicon oxide Janus structure nanoparticle, centrifuged and washed with water. get.

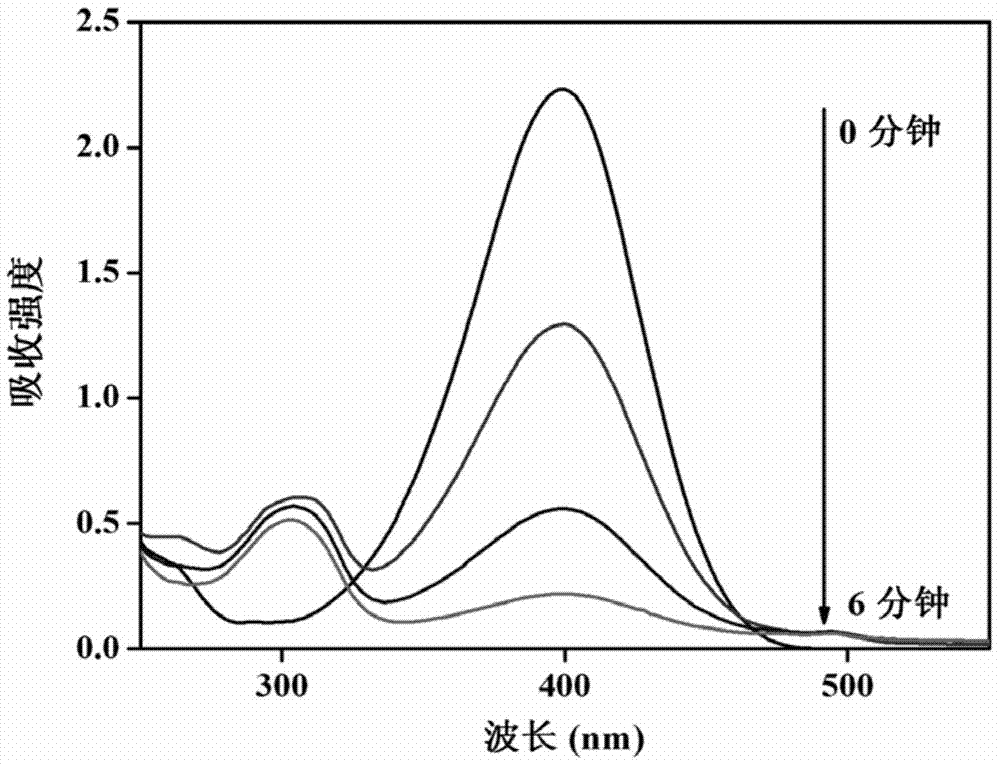

[0032] The beneficial effects of this embodiment are: (1) significantly enhance the catalytic properties of gold-silicon oxide Janus structure nanoparticles, which is beneficial to industrial applications; in the reduction reaction of nitrophenol, under the same conditions, the gold-oxidized The complete catalysis time of the silicon Janus structure nanoparticles is 10 minutes, and the half-covered ligands on the gold surface fall off after light irradiation, exposing part of the gold surface, and the complete catalysis time of the Janus structure nanoparticles is increased to 6 minutes. And whether it is illuminated or not, the catalytic rate of Janus' gold-silicon oxide (0.24min before i...

specific Embodiment approach 2

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the ethanol aqueous solution of gold-silicon oxide Janus structure nanoparticles is specifically prepared according to the following steps: 1. Gold nanoparticles were mixed with water to obtain a concentration of 10 -4 mmol / L~10 -3 mmol / L gold nanoparticle aqueous solution, drop the gold nanoparticle aqueous solution into the alcohol solvent to obtain a reaction system, and then mix the A solution with a concentration of 1mmol / L~10mmol / L under the stirring condition of 50rpm~400rpm Add the B solution with a concentration of 0.2mmol / L to 5mmol / L dropwise into the reaction system. After the dropwise addition, stir the reaction system at a speed of 50rpm to 400rpm for 1min to 10min, and then stir the reaction system at a speed of 50rpm to 400rpm. , stirring for 10min to 60min to obtain a reaction system containing gold nanoparticles coated with double ligands; the gold nano...

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the ultraviolet lamp is obtained after the ethanol aqueous solution of gold-silicon oxide Janus structure nanoparticles is irradiated, specifically according to the following steps: At a rotational speed of 50rpm-400rpm, use a UV lamp with a power of 0.1W-1000W to irradiate the ethanol aqueous solution of gold-silicon oxide Janus structure nanoparticles for 1min-1000min. Under the condition of ultrasonic power of 100W-500W, The irradiated gold-silicon oxide Janus structure nanoparticle ethanol aqueous solution is ultrasonically treated for 1min to 100min, then centrifuged and washed with water for 3 to 6 times, and finally dispersed into water for later use to obtain gold-silicon oxide with high catalytic properties Janus structured nanoparticles;

[0038] The ultraviolet lamp is one or a combination of single wavelength and continuous wavelength of ultraviolet light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com