TiO<2>@SiO<2> photocatalyst and application of same to photocatalytic reduction for CO<2>

A photocatalyst and catalyst technology, which is applied in the field of TiO2SiO2 photocatalyst and photocatalytic reduction of CO2, can solve the problem that the influence of reduction activity has not attracted certain attention, lack and other problems, and achieve outstanding effect, simple preparation method and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

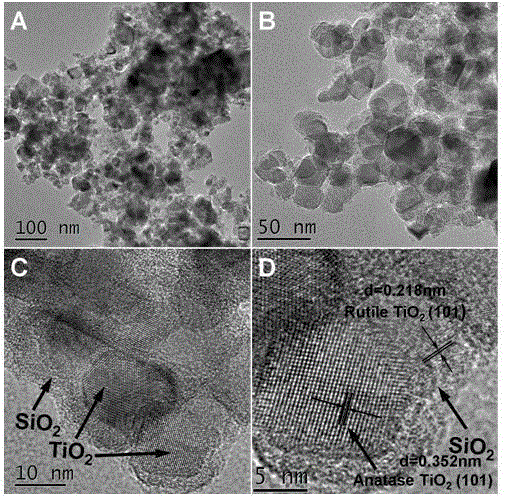

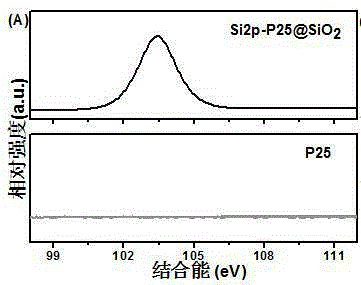

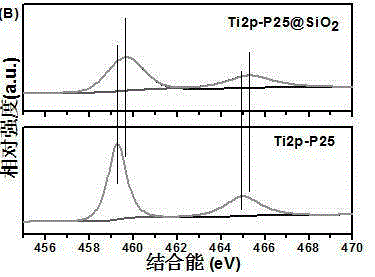

Image

Examples

Embodiment 1

[0030] 20mgTiO 2 The photocatalyst is placed in a quartz reaction tube with a volume of 25ml, the reaction tube is evacuated and filled with pure carbon dioxide gas, and the operation is repeated three times; after that, 0.5ml of evacuated liquid water is injected into the quartz tube with a syringe to keep CO 2 The final pressure is 8kPa; after illuminating the above system (simulating sunlight) for 8h, use a sampling needle to take out 0.3ml of reactive gas from the reaction tube and analyze it by gas chromatography; calculated, H 2 The rate of formation is 2.17μmolg -1 h -1 , The generation rate of CO is 1.79μmolg -1 h -1 , CH 4 The rate of formation is 0.77μmolg -1 h -1 , CO 2 The conversion rate is 2.62 μmolg -1 h -1 , The selectivity to CO is 25.23%.

Embodiment 2

[0032] Mix 2ml of tetraethylorthosilicate (TEOS), 4ml of ethanol (ETOH) and 2ml of 1M hydrochloric acid solution (HCl) and stir evenly to obtain a TEOS hydrolysate; add 0.1g of TiO 2 Disperse uniformly by ultrasonic in 1ml of water, then mix with 0.08ml of the above TEOS hydrolyzate and stir evenly; slowly add 1M sodium hydroxide solution (NaOH) to the above mixed suspension until the mixture is dehydrated into a gel, and stored for 24h to age the gel , And finally drying to obtain gel; grinding the gel to obtain TiO 2 5%SiO 2 Powder samples.

[0033] 20mgTiO 2 5%SiO 2 The photocatalyst is placed in a quartz reaction tube with a volume of ~25ml, the reaction tube is evacuated and filled with pure carbon dioxide gas, and the operation is repeated three times; after that, 0.5ml of evacuated liquid water is injected into the quartz tube with a syringe to keep CO 2 The final pressure is 8KPa; after illuminating the above system (simulating sunlight) for 8h, use a sampling needle to tak...

Embodiment 3

[0035] Mix 2ml of tetraethylorthosilicate (TEOS), 4ml of ethanol (ETOH) and 2ml of 1M hydrochloric acid solution (HCl) and stir evenly to obtain a TEOS hydrolysate; add 0.1g of TiO 2 Disperse uniformly by ultrasonic in 1ml of water, then mix with 0.15ml of the above TEOS hydrolysate and stir evenly; slowly add 1M sodium hydroxide solution (NaOH) to the above mixed suspension until the mixed liquid is dehydrated into gel, and stored for 24h to age the gel , And finally drying to obtain gel; grinding the gel to obtain TiO 2 10%SiO 2 Powder samples. 20mgTiO 2 10%SiO 2 The photocatalyst is placed in a quartz reaction tube with a volume of 25ml, the reaction tube is evacuated and filled with pure carbon dioxide gas, and the operation is repeated three times; after that, 0.5ml of evacuated liquid water is injected into the quartz tube with a syringe to keep CO 2 The final pressure is 8KPa; after illuminating the above system (simulating sunlight) for 8h, use a sampling needle to take o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com