Bubbler

A bubbler and bubbling technology, which is applied in the field of gas bubblers and cylinder bubbling devices, can solve the problems of poor distribution uniformity and small gas holdup, achieve length reduction, increase gas-liquid contact amount, and benefit fully The effect of the contact reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

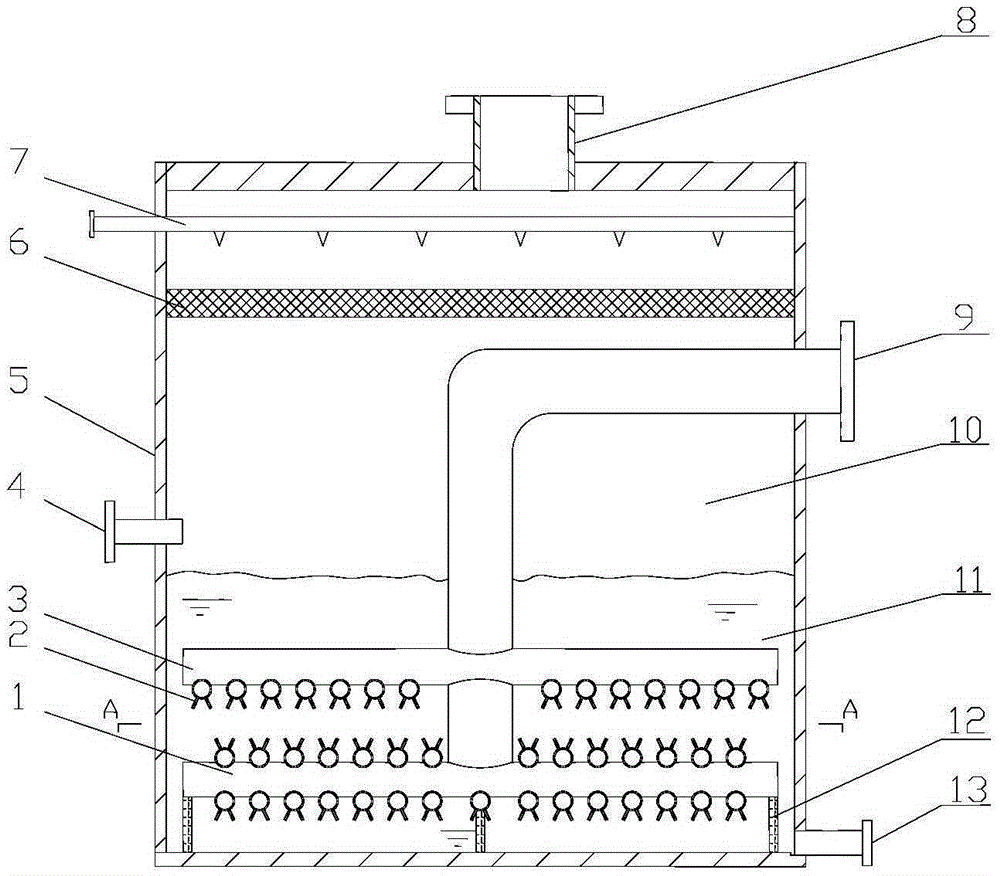

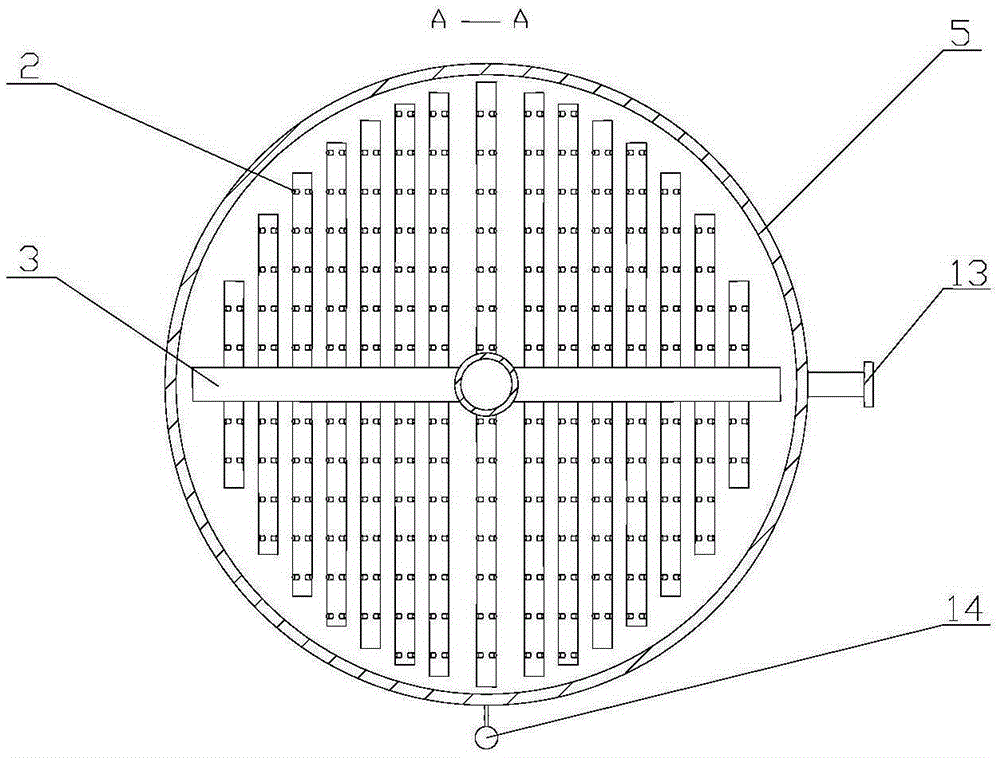

[0018] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the upper part of the cylinder body 5 is a purified gas chamber 10, and the lower part is an absorption liquid chamber 11. In the purified gas chamber 10, a mist eliminator 6 for removing the purified gas water mist is installed, and the connection with the cylinder body is a detachable bolt Connect, there are several spray pipes 7 for cleaning the mist eliminator on it, and several shower nozzles are provided. The inlet pipe 9 used for exhaust gas entry is welded on the cylinder wall, and one end extends into the cylinder body and is vertically connected and communicated with the primary air distribution pipe 1 . The first-level gas distribution pipe 2, multiple secondary gas distribution pipes 1 and injection pipes 2 parallel to each other form a disc gas distributor, and the outlets of all injection pipes 2 are located on the same horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com