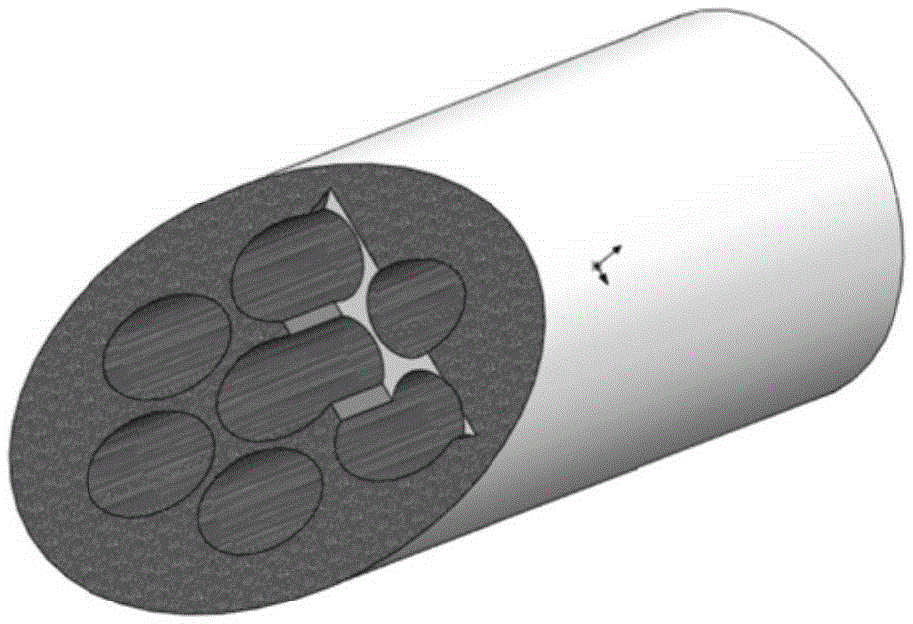

Preparation method of nerve defect repair material of vessel basilar membrane imitating structure

A technology for repairing materials and tube structures, applied in medical science, prostheses, etc., can solve the problem of not really simulating the fiber arrangement of nerve basement membrane tubes, and achieve the effect of high permeability and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 prepares 8% (w / v) PLGA electrospinning stock solution

[0037] Weigh 0.4g PLGA (85:25) and 0.1g extracellular matrix dry powder, put them into the container, add 5ml chloroform solution, and prepare the electrospinning stock solution of PLGA8% (w / v), after magnetic stirring for 12 hours, Seal and store at 4°C for later use.

[0038]Among them, the preparation of extracellular matrix dry powder: the experimental group has related patent applications, see the preparation and application of neural tissue-derived tissue engineering scaffold materials for details. National invention patent: ZL201010107529.8.

Embodiment 2

[0039] Embodiment 2 prepares 10% (w / v) PLGA electrospinning stock solution

[0040] Weigh 0.5g of PLGA (85:25) and 0.2g of extracellular matrix dry powder, put them into a container, add 5ml of chloroform solution, and prepare an electrospinning stock solution of PLGA10% (w / v), and stir it magnetically for 12 hours. Seal and store at 4°C for later use.

Embodiment 3

[0041] Embodiment 3 prepares 12% (w / v) PLGA electrospinning stock solution

[0042] Weigh 0.6g PLGA (85:25) and 0.3g extracellular matrix dry powder, put them in the container, add 5ml chloroform solution, and prepare the electrospinning stock solution of PLGA12% (w / v), after magnetic stirring for 12 hours, Seal and store at 4°C for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com