Adjustable pair of roller gap surrounding wolfberry picking head

A technology of roller gap and picking head, which is applied in the fields of picking machines, agricultural machinery and implements, and applications, can solve the problems of limited automation of wolfberry picking, inability to adjust the gap between rollers, and reduction of the working area of the picking head, so as to speed up agricultural production. The effect of scientific progress, promoting rural economic development and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

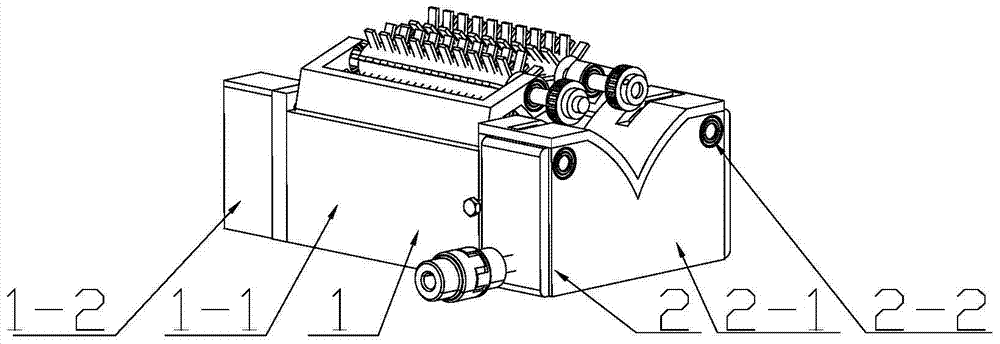

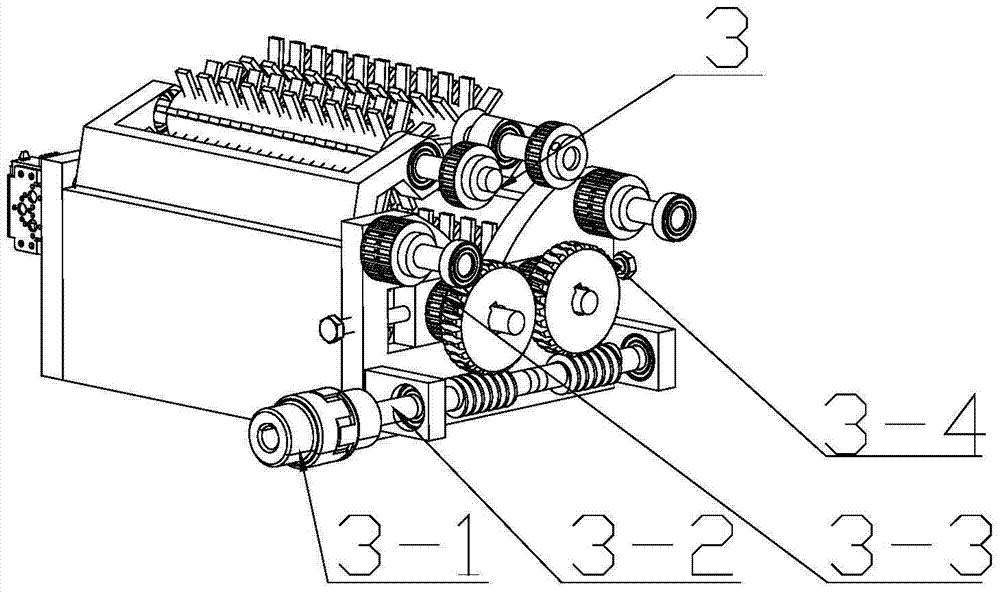

[0044] The surrounding wolfberry picking head with adjustable roller clearance includes a power supply system 10 , a drive system 8 , a picking head housing 1 and a main roller 5 arranged inside the picking head housing 1 . The main rollers 5 include a forward rotating main roller 5-1 and a reverse rotating main roller 5-2, and the forward rotating main roller 5-1 and the reverse rotating main roller 5-2 rotate in opposite directions. The adjustable roller gap surrounding type wolfberry picking head also includes a transmission system 3 and an auxiliary roller 6, and the auxiliary roller includes a forward rotation auxiliary roller 6-1 and a reverse rotation auxiliary roller 6-2. Roller 6-1 and counter-rotating secondary roller 6-2 rotate oppositely. The forward-rotating auxiliary roller 6-1 is arranged above the forward-rotating main roller 5-1, and the counter-rotating auxiliary roller 6-2 is arranged above the counter-rotating main roller 5-2. Both the main roller 5 and th...

Embodiment 2

[0051] Different from Embodiment 1, the forward transmission device 3-3 also includes a key I 3-3d, and the forward rotation turbine 3-3c is mounted on the second transmission shaft I 3-3b through the key I 3-3d . The reverse transmission device 3-5 also includes a key II 3-4d, and the counter-rotating turbine 3-4c is mounted on the second transmission shaft II 3-4b via the key II 3-4d.

Embodiment 3

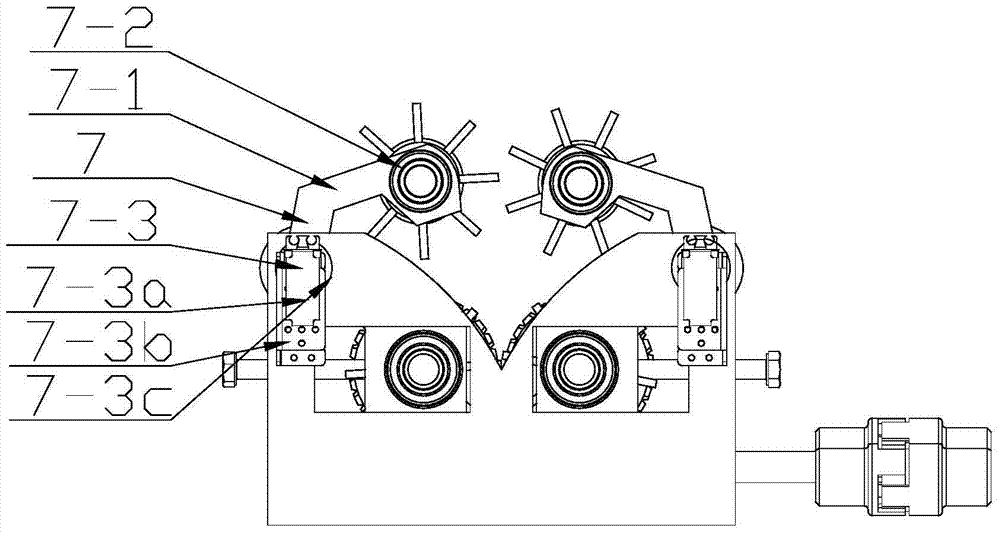

[0053] Different from Example 1, the adjustable pair of roller gap surrounding type wolfberry picking head also includes an opening and closing opening 7, and the opening and closing opening 7 includes an opening and closing opening main body 7-1, an auxiliary roller bearing 7-2, and a steering gear 7-3 And protruding pin 7-4, described steering gear 7-3 is arranged on the rear end of picking head housing 1. One end of the opening and closing mouth main body 7-1 is installed on the picking head housing 1 through the convex pin 7-4, and then connected to the steering wheel 7-3c of the steering gear 7-3. The other end of the opening and closing body 7-1 is connected with the auxiliary roller bearing 7-2. The auxiliary roller bearing 7-2 is the bearing of the third transmission shaft I 3-3h and the third transmission shaft II 3-4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com