Transformer with rectangular section iron core

A rectangular cross-section, transformer technology, applied in the field of transformers, can solve the problems of waste, labor and time, and achieve the effect of saving waste, simplifying stacking process, and saving time for loading and unloading materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

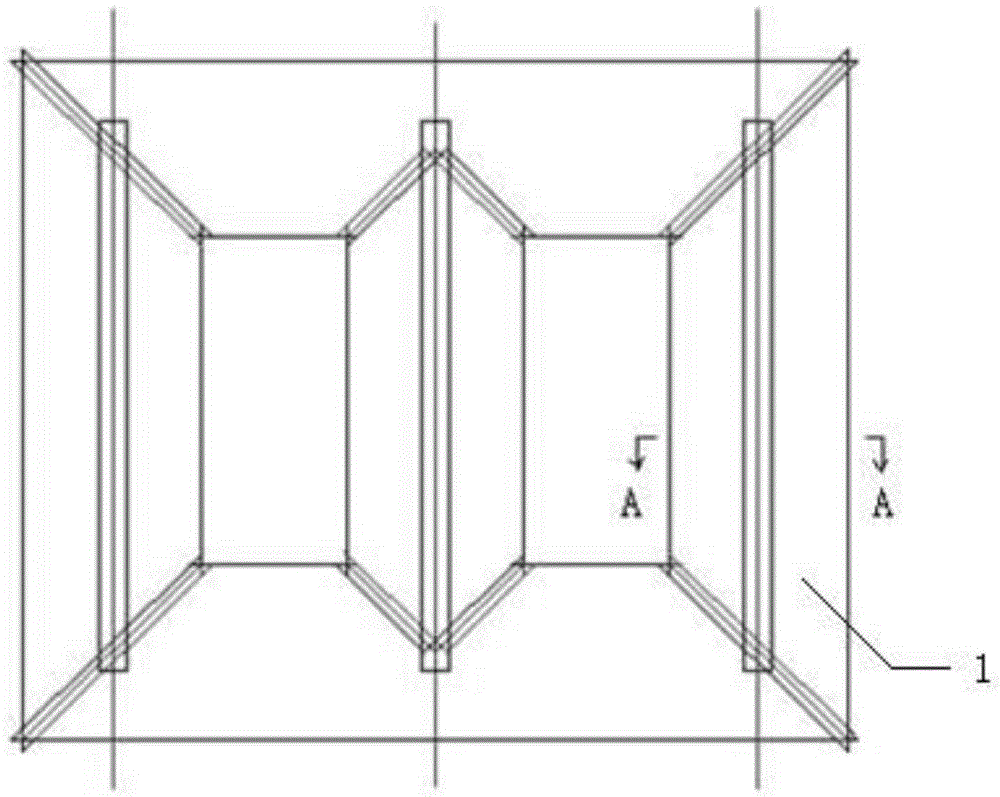

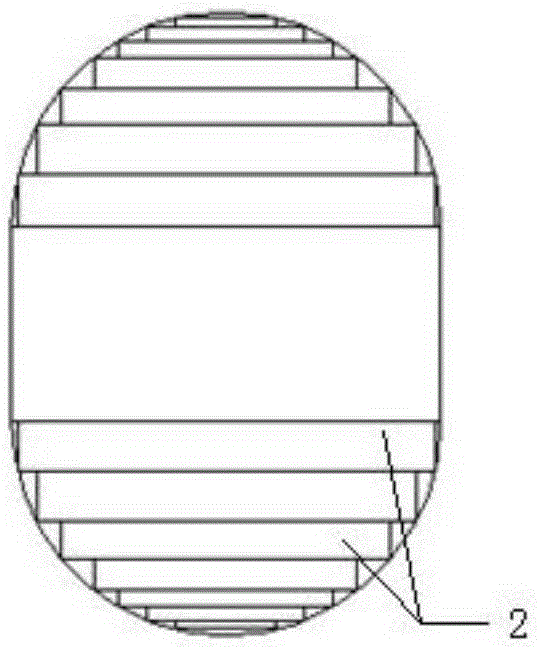

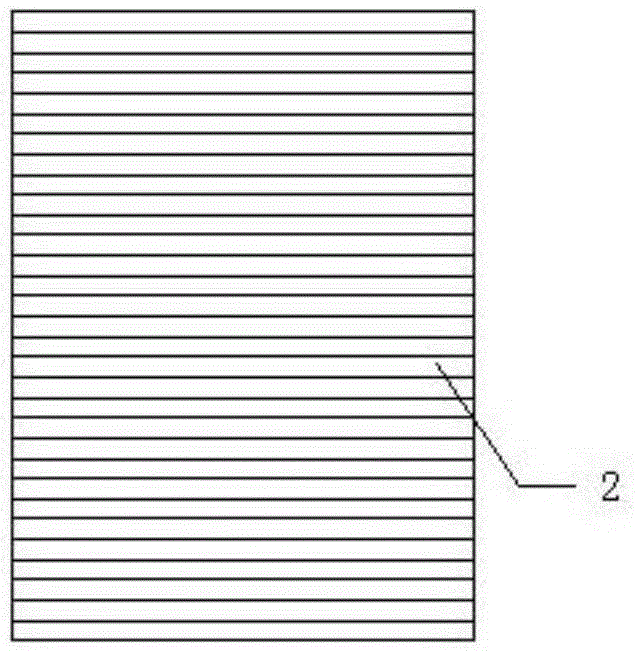

[0013] Such as image 3 As shown, a transformer with a rectangular cross-section iron core includes an iron core 1 and a coil. The coil has two or more windings, wherein the winding connected to the power supply is called the primary coil, and the remaining windings are called the secondary coil. The core 1 is formed by stacking several silicon steel sheets 2 with the same width, and the cross section of the iron core is rectangular.

[0014] Preferably, the area of the rectangular section of the iron core 1 is the same as that of the iron core with an oblong or circular section.

[0015] In order to reduce eddy currents, an insulation resistance of several ohms to tens of ohms is provided between the silicon steel sheets 2 in the iron core 1 .

[0016] Considering that the silicon steel sheet itself is also a conductor, under the action of the AC magnetic flux, an indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com