Batch processing machine scheduling method of dynamically-changed weight

A technology of dynamic changes and scheduling methods, which is applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., and can solve the problems of reduced accuracy of optimal scheduling solutions and deviation of the optimal scheduling process of batch processing machines from the actual situation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further:

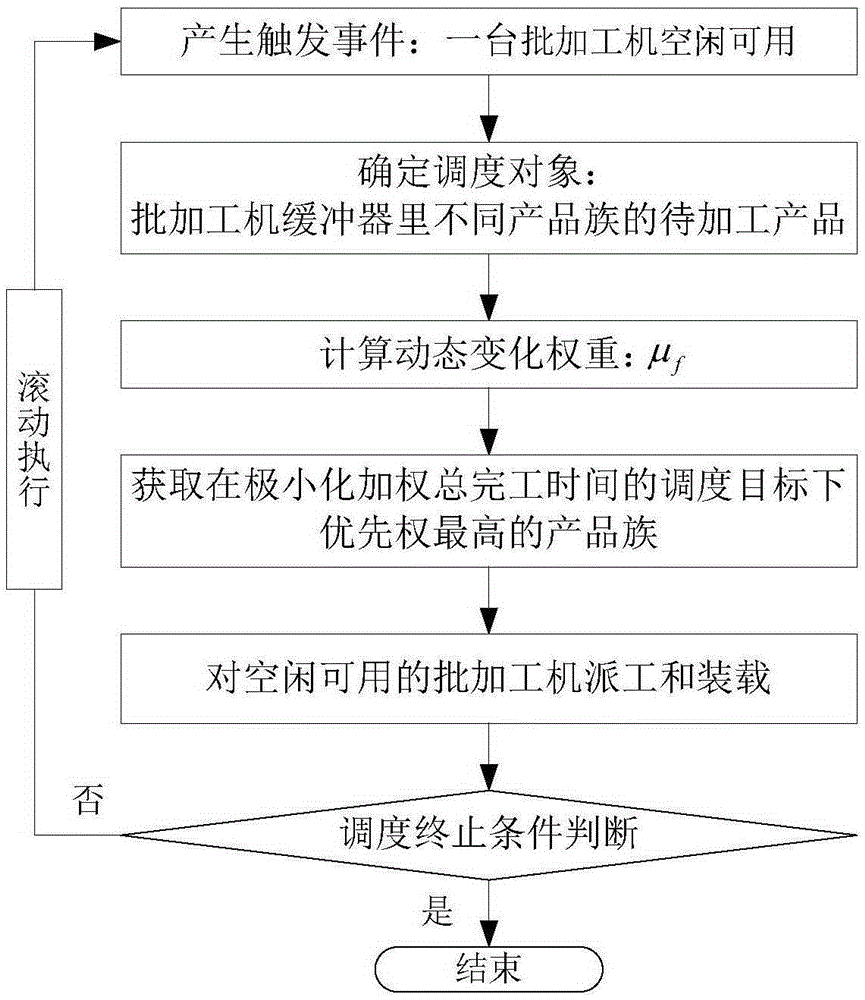

[0030] A batch processing machine scheduling method under dynamically changing weights provided by the present invention includes generating trigger events, determining scheduling objects, calculating dynamically changing weights, obtaining the product family with the highest priority, dispatching and dispatching workers to idle and available batch processing machines Loading, scheduling termination condition judgment.

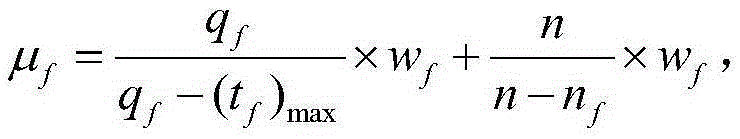

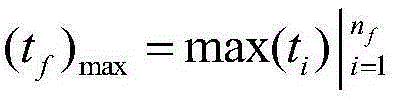

[0031] The dynamic change weight includes the dynamic change of the number of products to be processed in different product families, the dynamic change of the arrival time of the products to be processed in the same product family, and the constraint requirements with a waiting time limit. The dynamic change weight calculation model is as follows

[0032] μ f = q ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com