Pulverized coal flow adjusting valve

A flow control valve and pulverized coal technology, applied in the field of control valves, can solve the problems of increasing equipment maintenance costs, damage to bellows valve stems, shortening the service life of control valves, etc., and achieves compact valve structure, saving operating costs, and high flow capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

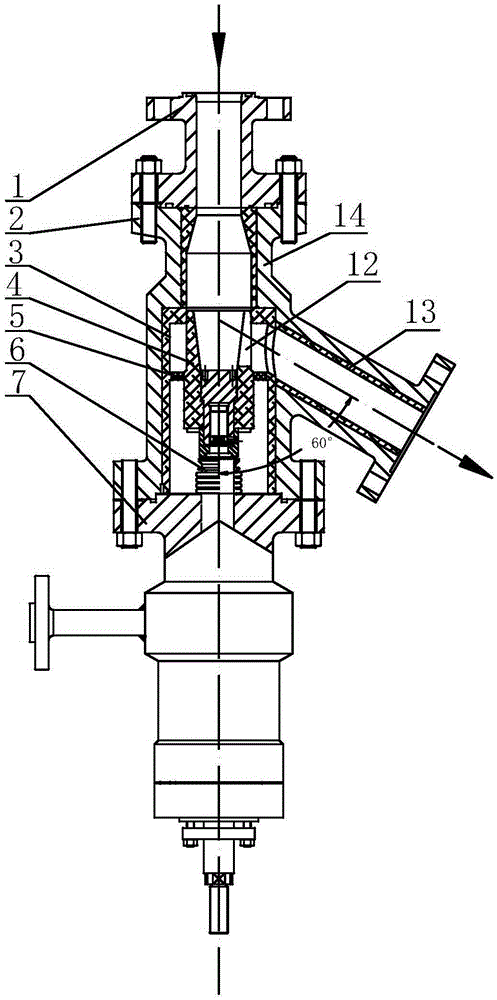

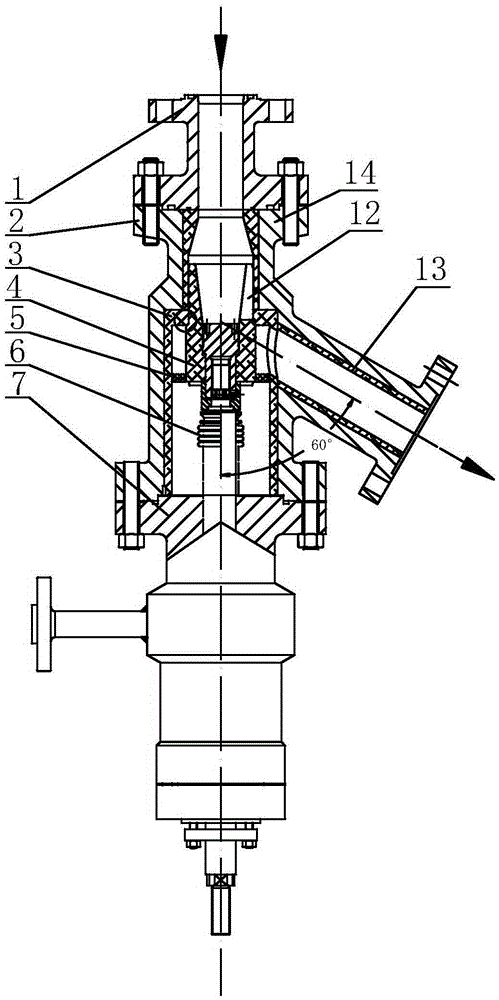

[0027] The structure of the present invention will be further described below in conjunction with the drawings:

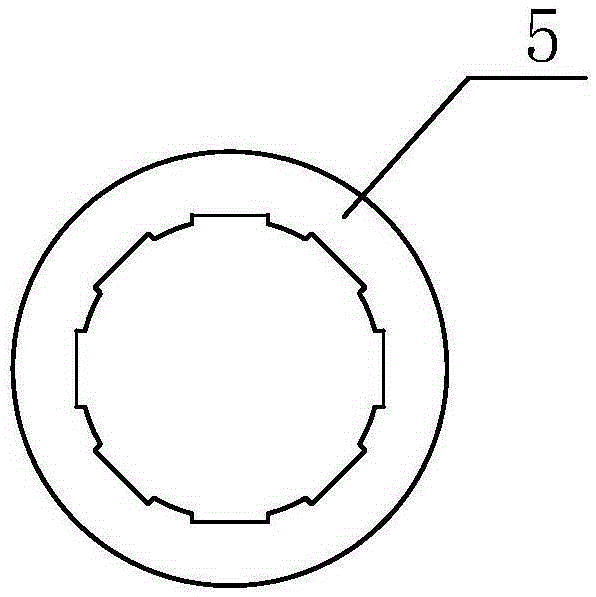

[0028] A pulverized coal flow regulating valve, comprising a valve body 2 provided with a fluid inlet and a fluid outlet. The valve body 2 is provided with a valve core 4 for adjusting the fluid flow. The valve body 2 and The gap between the valve core 4 is connected with the valve body bushing and sleeved on the outside of the valve core 4 and is slidingly fitted with the valve core 4 to prevent debris from entering the gap between the valve body 2 and the valve core 4 Retaining ring 5 at the valve cover 7. When the regulating valve is used to adjust the flow of air-borne pulverized coal, because the gap between the valve body 2 and the valve core 4 is provided with a retaining ring 5, the debris in the air-borne pulverized coal can be effectively intercepted by the retaining ring 5. It prevents the foreign matter in the pulverized coal from entering the valve cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com