Remote-delivery bladeless ventilating system used in gunpowder and explosive field

A technology of ventilation system and explosives, applied in the field of ventilation system, can solve the problems of spark explosion, new bladeless ventilation system has not yet appeared, long flow channel and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

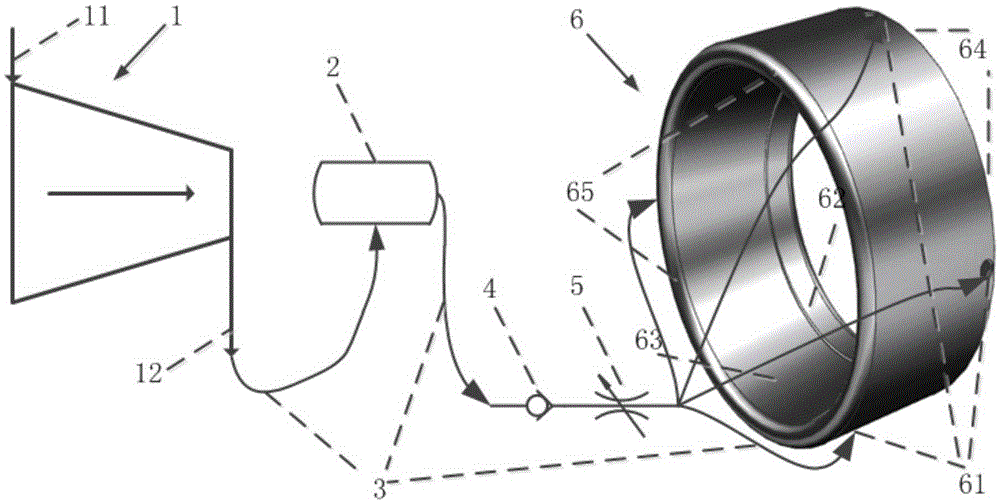

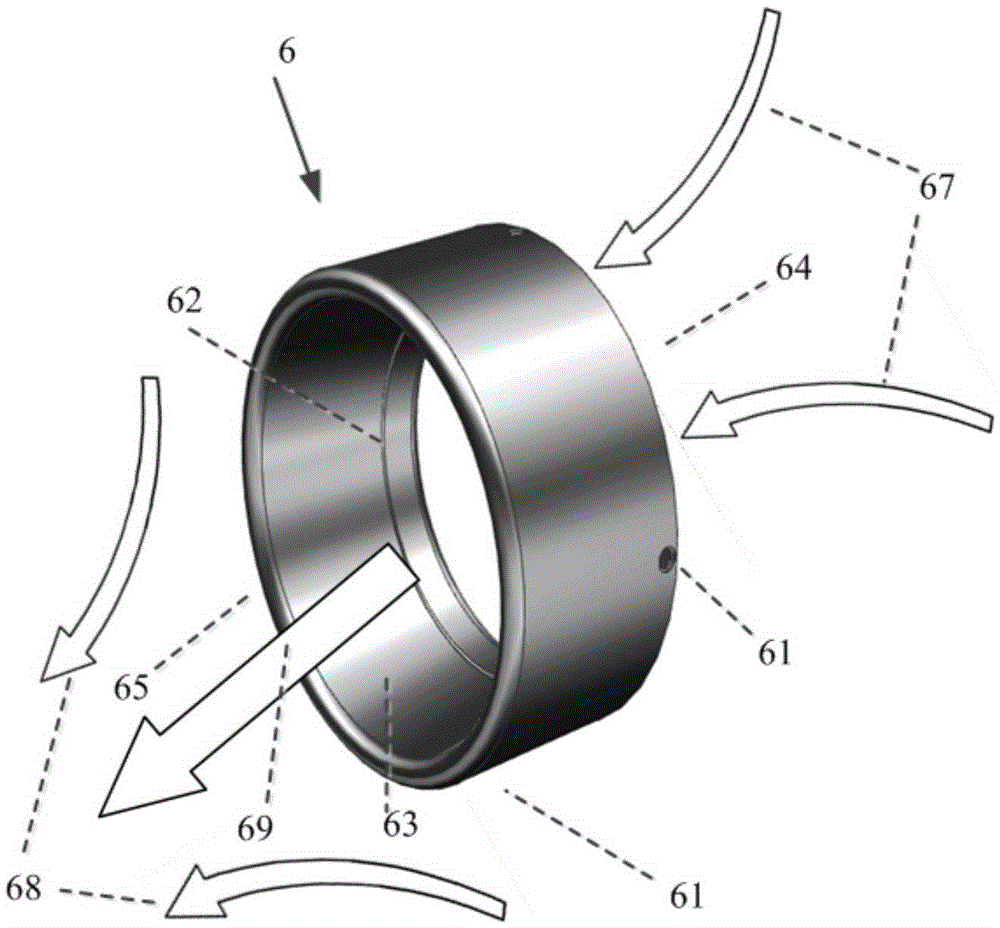

[0028] figure 1 Shown is a schematic diagram of the overall composition of the remote transmission bladeless fan used in the explosives field of the present invention, including an air source 1, an air storage tank 2, an air pipe 3, a one-way valve 4, a throttle valve 5, and a ventilation frame 6, wherein the air source 1 , gas storage tank 2, one-way valve 4, throttle valve 5, and ventilation frame 6 are connected in series through the air pipe 3 in sequence. It can ensure that the air inhaled by the air source inlet 11 is clean and free of dangerous materials such as explosive dust or particles. At the same time, the noise generated when the air source 1 is working is isolated and will not cause noise pollution to the use occasion. Because the air source 1 can be used as a central air source for multiple ventilation frames 6, it is necessary to consider the change of the air volume provided by the terminal to the air source 1 in different time periods, and install an air sto...

Embodiment 2

[0035] figure 1 Shown is a schematic diagram of the overall composition of the remote transmission bladeless fan used in the explosives field of the present invention, including an air source 1, an air storage tank 2, an air pipe 3, a one-way valve 4, a throttle valve 5, and a ventilation frame 6, wherein the air source 1 , gas storage tank 2, one-way valve 4, throttle valve 5, and ventilation frame 6 are connected in series through the air pipe 3 in sequence. It can ensure that the air inhaled by the air source inlet 11 is clean and free of dangerous materials such as explosive dust or particles. At the same time, the noise generated when the air source 1 is working is isolated and will not cause noise pollution to the use occasion. Because the air source 1 can be used as a central air source for multiple ventilation frames 6, it is necessary to consider the change of the air volume provided by the terminal to the air source 1 in different time periods, and install an air sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com