Supercharged applied ignition internal combustion engine with exhaust-gas turbocharging and method for operating an internal combustion engine of said type

An internal combustion engine, supercharged technology, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve problems such as limiting maximum torque and reducing fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

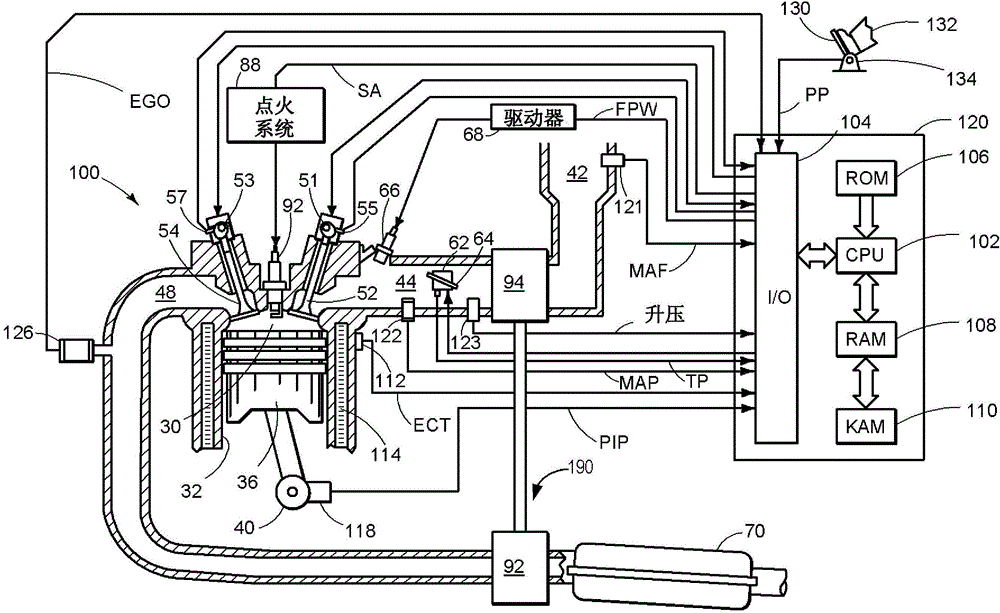

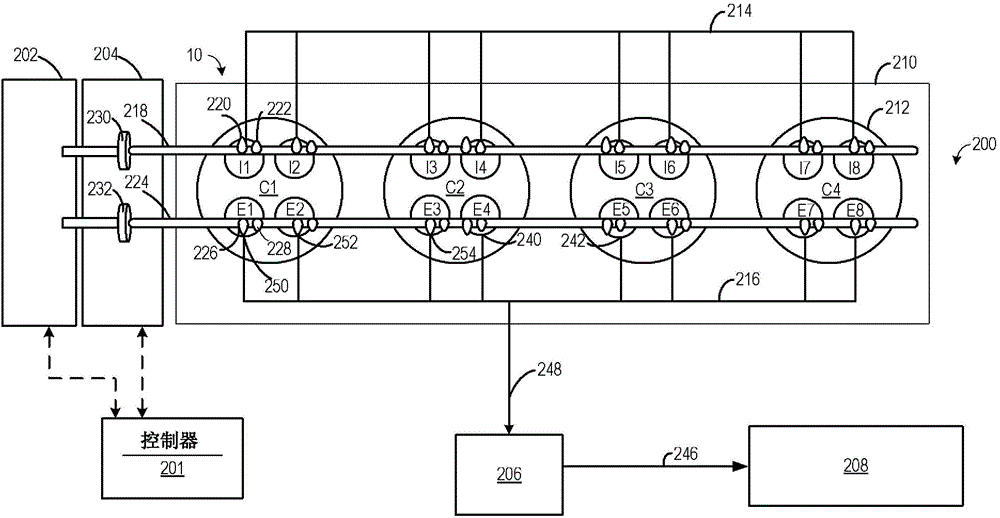

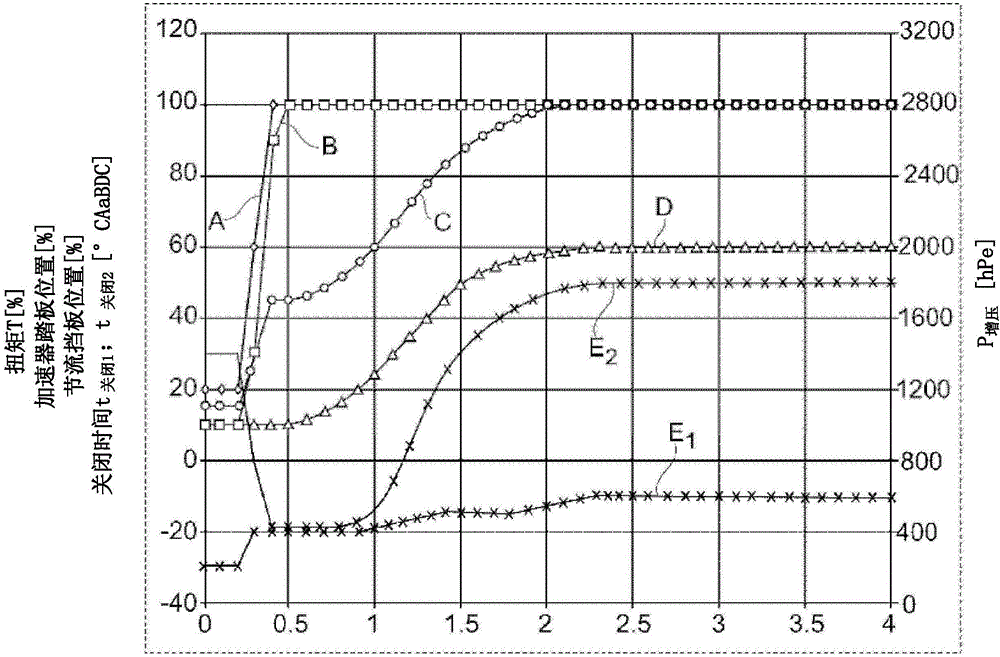

[0016] The present application relates to a supercharged application ignition internal combustion engine, which comprises: at least one cylinder head and at least one cylinder, each cylinder has at least two air inlets and at least one air outlet, and the air inlet is used for The air system supplies charge air, the outlet port is used to discharge the exhaust gas via the exhaust discharge system; at least one throttle baffle is arranged in the air intake system and is used for load control; and at least one exhaust gas turbocharger is provided. each exhaust turbocharger includes a turbine arranged in the exhaust discharge system and a compressor arranged in the intake system; and a knock regulator which provides protection against Ignition delay Δ required for knock 点火 .

[0017] The present application also relates to a method for operating an internal combustion engine of the type described, wherein each cylinder comprises two intake ports for supplying charge air via an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com