Combined measurement method of acoustic and electric sensors for flow parameters of oil-gas-water three-phase flow

An acoustoelectric sensor and measurement method technology, applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of slow measurement response speed, total flow measurement error, difficult to measure flow conditions, etc., to improve the local flow rate and local concentration non-uniform distribution, high reliability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The method for combined measurement of flow parameters of oil-gas-water three-phase flow by acoustic and electric sensors mainly includes the following steps:

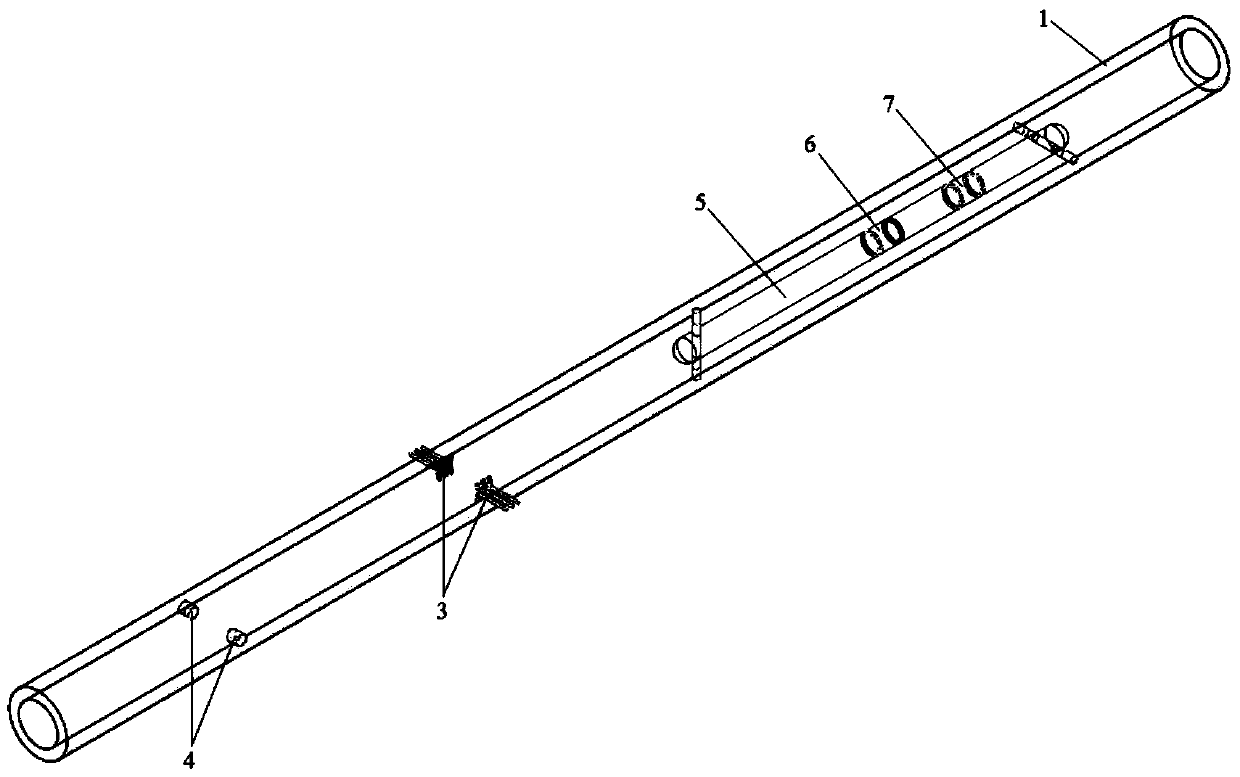

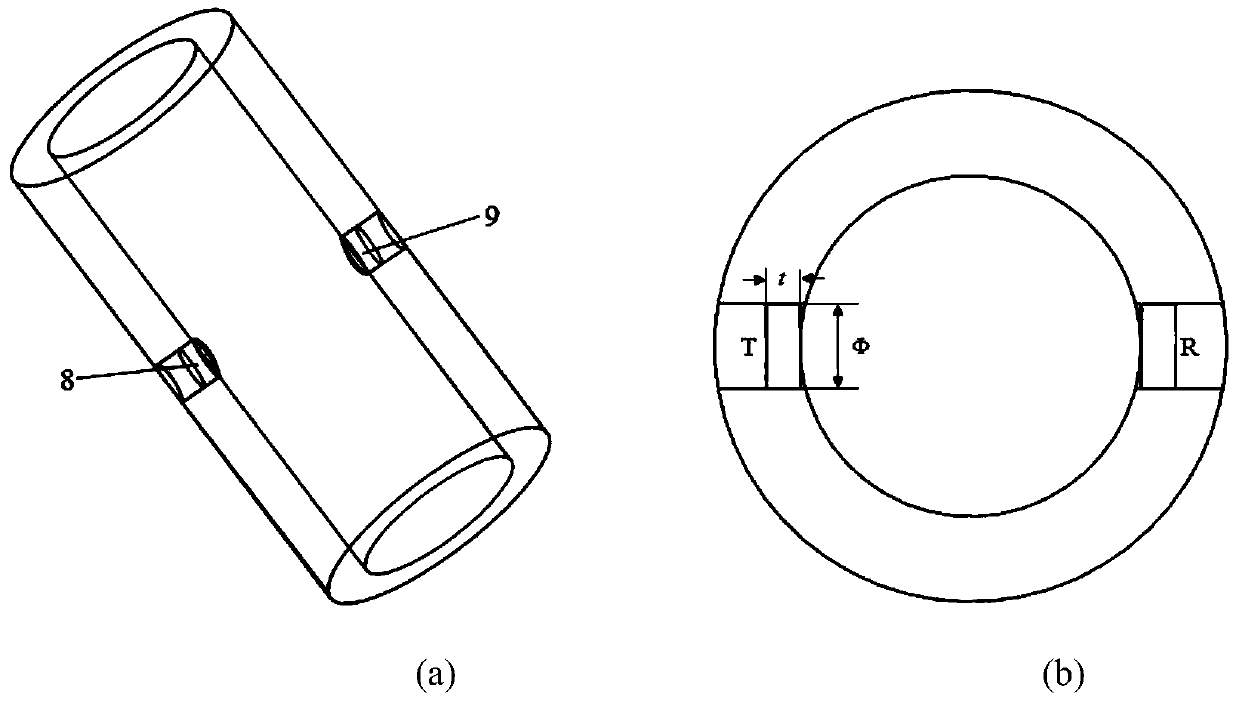

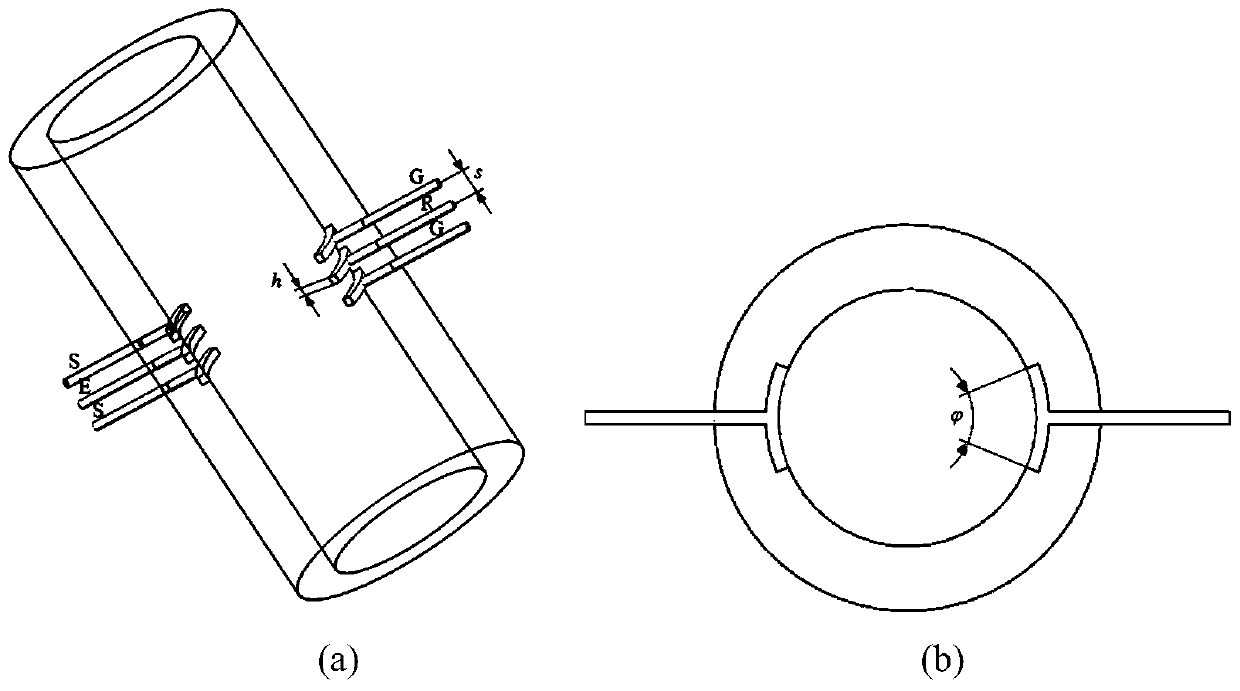

[0026] (1) Design an oil-gas-water three-phase flow acoustic-electric sensor combination measurement system for the measurement of relative velocity and phase-specific holdup (gas holdup, water holdup, oil holdup) of oil-gas-water three-phase flow where water is the continuous phase, The combination structure of its acoustic-electric sensor is as follows: figure 1 shown. Considering that the inner diameter of the measurement channel of the downhole flow-collection production profile production logging instrument is mostly 20mm, the acoustic-electric sensor combination of the present invention is installed in the vertical small pipeline (with an inner diameter of 20mm) sequentially from bottom t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com