Accurate time-delay presplitting blasting reinforcement coal seam gas extraction method

A technology of pre-splitting blasting and coal seam gas, which is applied in the field of enhanced extraction of coal seam gas by precise time-delay pre-splitting blasting, which can solve the problems of plastic flow consumption, excessive crushing and heat loss, and the scope and degree of influence of pre-splitting blasting coal seam permeability enhancement Small and other problems, to achieve the effect of enhancing the degree of stress relief, increasing the desorption rate, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

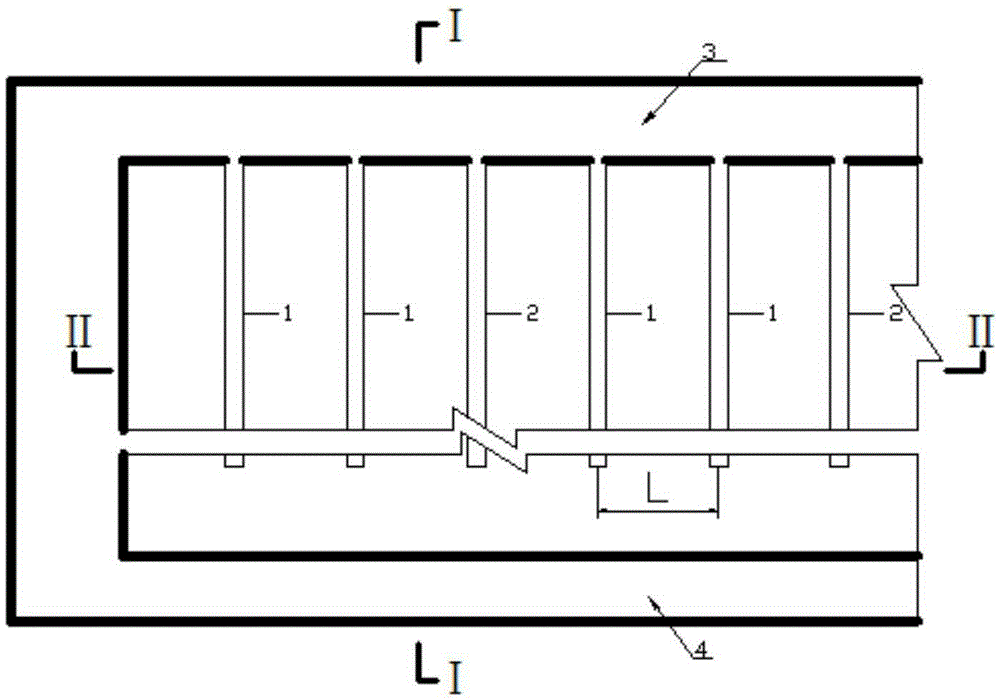

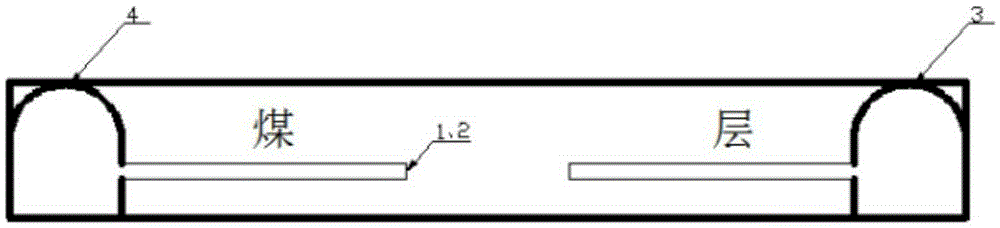

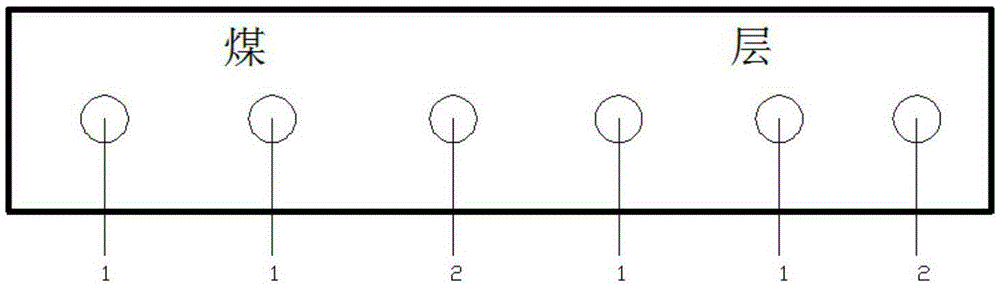

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] A method for enhanced extraction of coal seam gas by precise time-delayed pre-splitting blasting, comprising the following steps:

[0027] (1) According to the actual situation of the coal mine, design and arrange the coal mining face and production system according to the rules and regulations, and the production system includes the mine gas drainage system;

[0028] (2) Collect samples of the coal seam to be enhanced, and measure the physical properties of the coal seam to be enhanced, and the physical properties include permeability, porosity, firmness coefficient and natural vibration frequency;

[0029] (3) Select the blasting parameters according to the physical properties of the coal seam to be enhanced and the underground environmental conditions. The blasting parameters include the type of explosive, the amount of explosive, the diameter of the blasthol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com