Particle jet flow-based drill bit for impacting and breaking rocks

A technology of jet impingement and drill bit, applied in drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of slow drilling speed, prone to well deviation, affecting deep well and hard formation, development speed and benefit of unconventional oil and gas resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

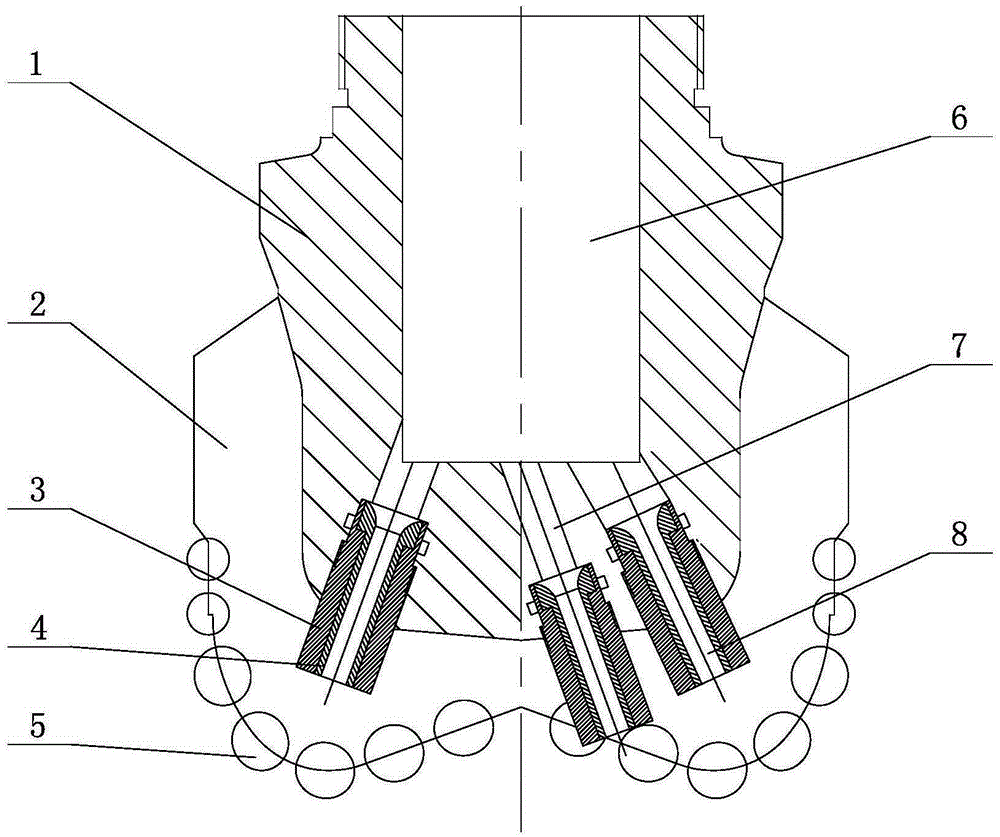

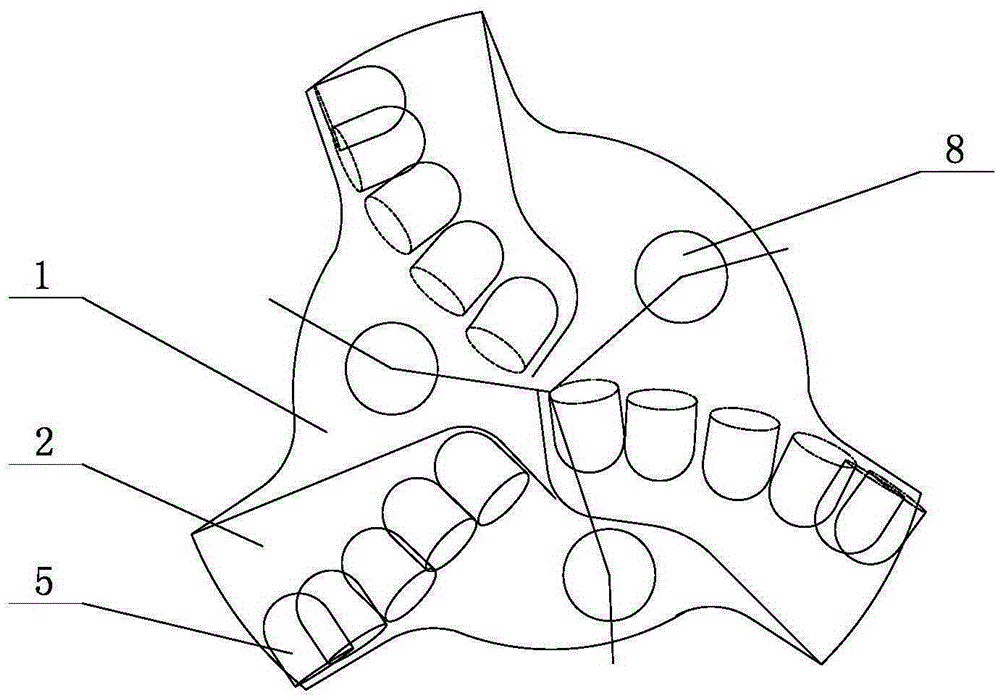

[0022] Such as Figure 1 ~ Figure 2 As shown, the particle jet impact rock-breaking drill bit of the present invention includes a drill bit body 1, a drill bit blade 2, a nozzle outer cover 3, an inner nozzle 4 and a cutting tooth 5, and a drill bit inner chamber 6 is arranged on the upper part of the drill bit body 1. The bottom of the cavity 6 is provided with a nozzle flow channel communicating with the inner cavity 6 of the drill bit. The bottom of the nozzle flow channel runs through the drill body 1. The nozzle flow channel includes the upper nozzle flow channel 7 and the lower nozzle flow channel. The inner nozzle 4 is installed in the lower nozzle flow channel. The inner nozzle flow channel 8 is formed in the nozzle 4, and the nozzle outer cover 3 is arranged between the inner nozzle 4 and the lower flow channel of the nozzle. There is a difference in diameter. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com