Method for improving overall performance of AA7075 aluminum alloy by adding rare earth Sb

An AA7075, comprehensive performance technology, applied in the field of AA7075 aluminum alloy performance optimization, can solve the problems of inability to heat treatment, low mechanical properties, etc., and achieve the effect of grain refinement, yield strength and fracture toughness, and optimization effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

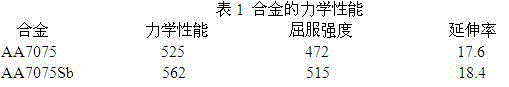

[0015] Based on AA7075 aluminum alloy (composition: Al-7.5Zn-1.5Mg-1.6Cu-0.2Zr), add 0% Sb (alloy AA7075) and 0.3% Sb (alloy AA7075Sb) respectively, raw materials are A00 pure aluminum, industrial Add in the form of pure magnesium, pure zinc, Al-Cu alloy, Al-Zr alloy and Al-Sb alloy. Alloy smelting is carried out in a resistance furnace, and the melt is poured into an iron mold at 720°C. The ingot was homogenized at 450°C for 24 hours, and then forged at 430°C by free forging to a forging with a thickness of 15mm, and the forging deformation in the height direction was 90%. The alloy after forging is solution treated by stepwise heating. The process is: (200°C, 24h)+(450°C, 1h)+(470°C, 1h). aging treatment.

[0016] Metallographic observations were performed on a LEICAMEF4A / M microscope. Microstructural analysis was carried out on JSM??6360 scanning electron microscope, JEM??100CX transmission electron microscope and TecnaiG220 transmission electron microscope. The thin fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com