rare earth ions 3+ adulterated 2 the si 4 no 6 The preparation method of c yellow fluorescent powder

A technology of yellow fluorescent powder and rare earth ions, which is applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc., can solve problems such as poor performance and high manufacturing cost of C-based phosphors, and reduce calcination temperature and time, and reduce calcination. Effects of time and excitation wavelength width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

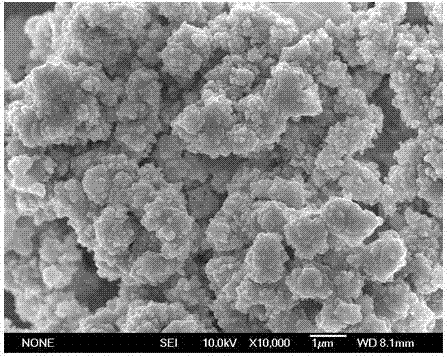

[0022] For existing Y 2 Si 4 N 6 The present invention provides a new preparation scheme for the problems existing in the preparation method of C-based phosphor. In the optimization method of the present invention, the precursor is prepared by the sol-gel method, and the powder is calcined by the carbothermal reduction nitriding method. The prepared yellow fluorescent powder has the advantages of cheap raw materials, short calcination time, mild experimental conditions and uniform grain size distribution. Etc. The invention provides a rare earth ion Ce 3+ Doped Y 2 Si 4 N 6 The invention discloses a preparation method of C yellow fluorescent powder, which belongs to the technical field of luminescent material preparation. The preparation method of the fluorescent powder mainly includes the following steps: according to the stoichiometric composition Y 2(1-x) Si 4 N 6 C: 2xCe for ingredients to form Y 2 Si 4 N 6The precursor raw materials of C are yttrium nitrate a...

Embodiment 1

[0039] According to the mass ratio converted into oxides is Y 2 o 3 :SiO2 2 :CeO 2 :C=8.12:9.09:0.65:1 (equivalent to Ce 3+ Doping amount x=5mol%; The actual amount of carbon is 2.2 times of the theoretical amount of carbon) to measure yttrium nitrate (Y(NO 3 ) 3 ), tetraethyl orthosilicate (TEOS), cerium nitrate (Ce(NO 3 ) 3 ), sucrose (C 12 h 22 o 11 ) each raw material, all above-mentioned raw materials are dissolved in the mixed solvent that deionized water and absolute ethanol are formed, wherein the total mass of raw material: the mass of deionized water: the mass of absolute ethanol=1.9:3:1, stirring and dissolving, drop Concentrated sulfuric acid (H 2 SO 4 ), the mass ratio of sucrose to concentrated sulfuric acid was 10:1, stirred at room temperature until the sol was formed, then put it into an oven, firstly kept it at 100°C for 6h, then kept it at 160°C for 6h, took it out and ground it, put it into a tube type In the furnace, the temperature rises from ...

Embodiment example 2

[0041] On the basis of Example 1, increase the consumption of C. According to the mass ratio converted into oxides is Y 2 o 3 :SiO2 2 :CeO 2 :C=5.59:6.67:0.48:1 (equivalent to Ce 3+ Doping amount x=5mol%; The actual amount of carbon is 3.0 times of the theoretical amount of carbon) to measure yttrium nitrate ((Y(NO 3 ) 3 ), tetraethyl orthosilicate (TEOS), cerium nitrate (Ce(NO 3 ) 3 ), sucrose (C 12 h 22 o 11 ) each raw material, all above-mentioned raw materials are dissolved in the mixed solvent that deionized water and absolute ethanol are formed, wherein the total mass of raw material: the mass of deionized water: the mass of absolute ethanol=1.9:3:1, stirring and dissolving, drop Concentrated sulfuric acid (H 2 SO 4 ), the mass ratio of sucrose to concentrated sulfur was 10:1, stirred at room temperature until the sol was formed, then put it into an oven, firstly kept it at 100°C for 6h, then kept it at 160°C for 6h, took it out and ground it, put it into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com