Process for the continuous preparation of epichlorohydrin

A technology of epichlorohydrin and chloropropene, which is applied in the direction of organic chemistry, can solve the problems of easy decomposition of peroxides when heated, low utilization rate of raw materials, and explosion hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

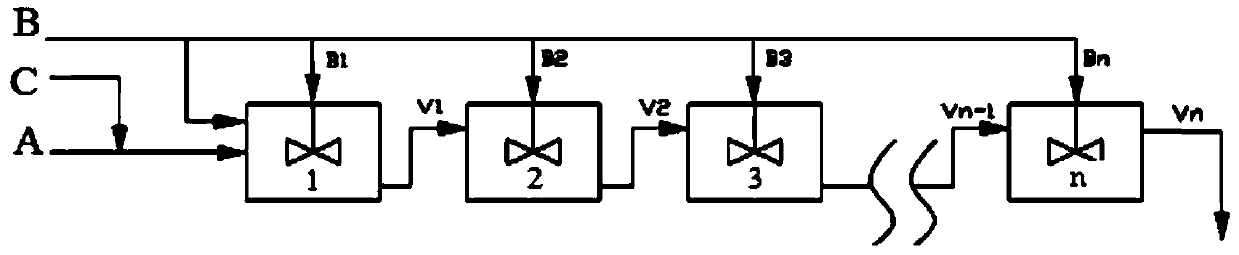

[0040] use figure 1 As shown in the flow process, 2 reactors are used in series, and the fresh chloropropene with a flow rate of 0.5 kg / h is mixed with the circulating chloropropene of 1.2 kg / h and the homogeneous molybdenum-based catalyst with a flow rate of 3.3 g / h. Enter. The flow rate is 2 kg / h. After the ethylbenzene solution containing 50% ethylbenzene hydroperoxide is mixed with 1 kg / h of circulating ethylbenzene, it is divided into 2 equal parts and enters from the top inlets of reactor 1 and reactor 2 respectively.

[0041] The weight ratio of molybdenum to ethylbenzene hydroperoxide is 0.00005, and allyl chloride: ethylbenzene hydroperoxide=3 (molar ratio).

[0042] The reaction temperature of the reactor 1 is 30° C., the reaction pressure is 0.1 MPa, and the conversion rate of ethylbenzene hydroperoxide is 60%.

[0043] The reaction temperature of the reactor 2 is 50° C., the reaction pressure is 0.1 MPa, and the conversion rate of ethylbenzene hydroperoxide is 10...

Embodiment 2

[0050] use figure 1 As shown in the flow process, 4 reactors are used in series, and the fresh chloropropene with a flow rate of 0.5 kg / h is mixed with the circulating chloropropene of 2 kg / h and the homogeneous molybdenum-based catalyst with a flow rate of 6.7 g / h. Enter. The flow rate is 2 kg / h. After the cumene solution containing 50% cumene hydroperoxide is mixed with 1 kg / h circulating cumene, it is divided into 4 equal parts and enters from the top inlet of reactor 1 to reactor 4 respectively. .

[0051] The weight ratio of molybdenum and cumene hydroperoxide is 0.0001, and allyl chloride: cumene hydroperoxide=5 (mol ratio).

[0052] The reaction temperature of the reactor 1 is 30° C., the reaction pressure is 0.1 MPa, and the conversion rate of cumene hydroperoxide is 30%.

[0053] The reaction temperature of the reactor 2 is 40° C., the reaction pressure is 0.1 MPa, and the conversion rate of cumene hydroperoxide is 60%.

[0054] The reaction temperature of the rea...

Embodiment 3

[0062] use figure 1 As shown in the flow process, 5 reactors are used in series, and the fresh chloropropene with a flow rate of 0.5 kg / h is mixed with the circulating chloropropene of 3 kg / h and the homogeneous molybdenum-based catalyst with a flow rate of 20 g / h. Enter. The flow rate is 2 kg / h. After the ethylbenzene solution containing 50% ethylbenzene hydroperoxide is mixed with 1 kg / h circulating ethylbenzene, it is divided into 5 equal parts and enters from the top inlet of the reactor 1 to the reactor 5 respectively.

[0063] The weight ratio of molybdenum to ethylbenzene hydroperoxide is 0.0003, and allyl chloride: ethylbenzene hydroperoxide=7 (molar ratio).

[0064] The reaction temperature of the reactor 1 is 30° C., the reaction pressure is 0.5 MPa, and the conversion rate of ethylbenzene hydroperoxide is 35%.

[0065] The reaction temperature of the reactor 2 is 50° C., the reaction pressure is 0.5 MPa, and the conversion rate of ethylbenzene hydroperoxide is 55%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com