3,4-epoxy-1-butene preparation method

A technology of butene and epoxy, which is applied in the field of preparation of 3,4-epoxy-1-butene, can solve the problems of waste, low conversion rate of raw materials and low product yield, and achieve good technical effect and technical economy Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

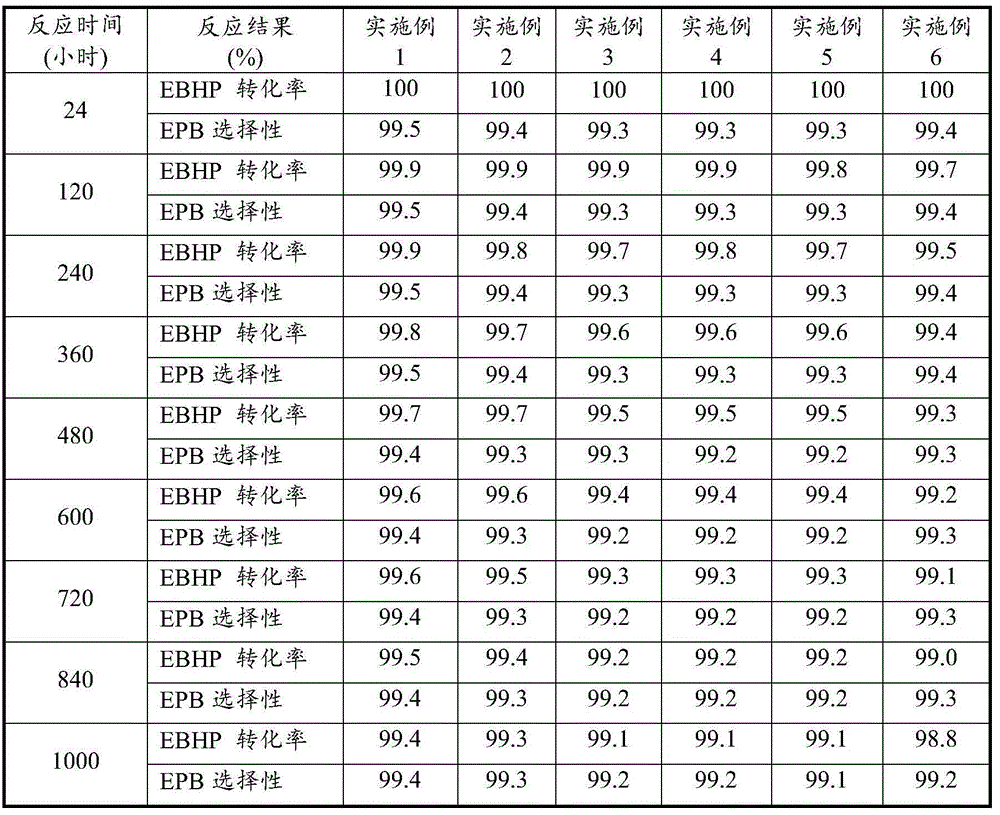

Examples

Embodiment 1

[0033] Under the conditions of 160°C, 0.4MPa, and controlling the volume content of tail oxygen to less than 5%, ethylbenzene and air undergo peroxidation reaction to obtain hydrogen peroxide ethylbenzene oxidation solution with a weight concentration of 10%, which is obtained by vacuum concentration. Concentration of 30% ethylbenzene hydrogen peroxide (EBHP) oxidation solution.

[0034] The above-mentioned ethylbenzene hydrogen peroxide oxidation solution with a weight concentration of 30% is carried out in a fixed bed reactor with 1,3-butadiene in the presence of a Ti-HMS catalyst (the weight percentage of titanium is 1.6%) Epoxidation produces 3,4-epoxy-1-butene, α-methylbenzyl alcohol and a small amount of acetophenone. Wherein 1,3-butadiene / EBHP=4 (molar ratio), the gravimetric space velocity of EBHP=3 hours -1 , the reaction temperature is 105°C, and the reaction pressure is 3.5MPa.

[0035] Pass the reaction mixture into a 1,3-butadiene recovery tower to recover exces...

Embodiment 2

[0037] Under the conditions of 150°C, 0.3MPa, and controlling the volume content of tail oxygen to less than 5%, ethylbenzene and air undergo peroxidation reaction to obtain hydrogen peroxide ethylbenzene oxidation solution with a weight concentration of 10%, which is obtained by vacuum concentration. Concentration of 28% ethylbenzene hydroperoxide (EBHP) oxidation solution.

[0038] The above weight concentration is 28% ethylbenzene hydrogen peroxide oxidation solution in the presence of Ti-MCM41 catalyst (the weight percentage of titanium is 2.0%), and 1,3-butadiene is cyclized in a fixed bed reactor The oxidation reaction generates 3,4-epoxy-1-butene, α-methylbenzyl alcohol and a small amount of acetophenone. Wherein 1,3-butadiene / EBHP=4 (molar ratio), the gravimetric space velocity of EBHP=3 hours -1 , the reaction temperature is 105°C, and the reaction pressure is 3.5MPa.

[0039] Pass the reaction mixture into the butadiene recovery tower to recover excess 1,3-butadien...

Embodiment 3

[0041] Under the conditions of 155°C, 0.35MPa, and controlling the volume content of tail oxygen to less than 5%, ethylbenzene and air undergo peroxidation reaction to obtain hydrogen peroxide ethylbenzene oxidation solution with a weight concentration of 10%, which is obtained by vacuum concentration. Concentration of 30% ethylbenzene hydrogen peroxide (EBHP) oxidation solution.

[0042] The above weight concentration is 30% ethylbenzene hydrogen peroxide oxidation solution in the presence of Ti-TUD-1 catalyst (the weight percentage of titanium is 1.5%), in a fixed bed reactor and 1,3-butadiene The epoxidation reaction generates 3,4-epoxy-1-butene, α-methyl benzyl alcohol and a small amount of acetophenone. Wherein 1,3-butadiene / EBHP=4 (molar ratio), the gravimetric space velocity of EBHP=3 hours -1 , the reaction temperature is 105°C, and the reaction pressure is 3.5MPa.

[0043] Pass the reaction mixture into the butadiene recovery tower to recover excess 1,3-butadiene fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com