Method for circularly trapping SO2 and CO2 by using calcium-based absorbent

A calcium-based absorbent, fluidized bed technology, applied in the field of calcium-based absorbent to capture sulfur dioxide and carbon dioxide, can solve the problems of increasing economic cost, increasing the input of calcium-based absorbent, affecting carbonation reaction, etc. Reduce system energy consumption and economic cost, good technical economy, avoid the effect of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

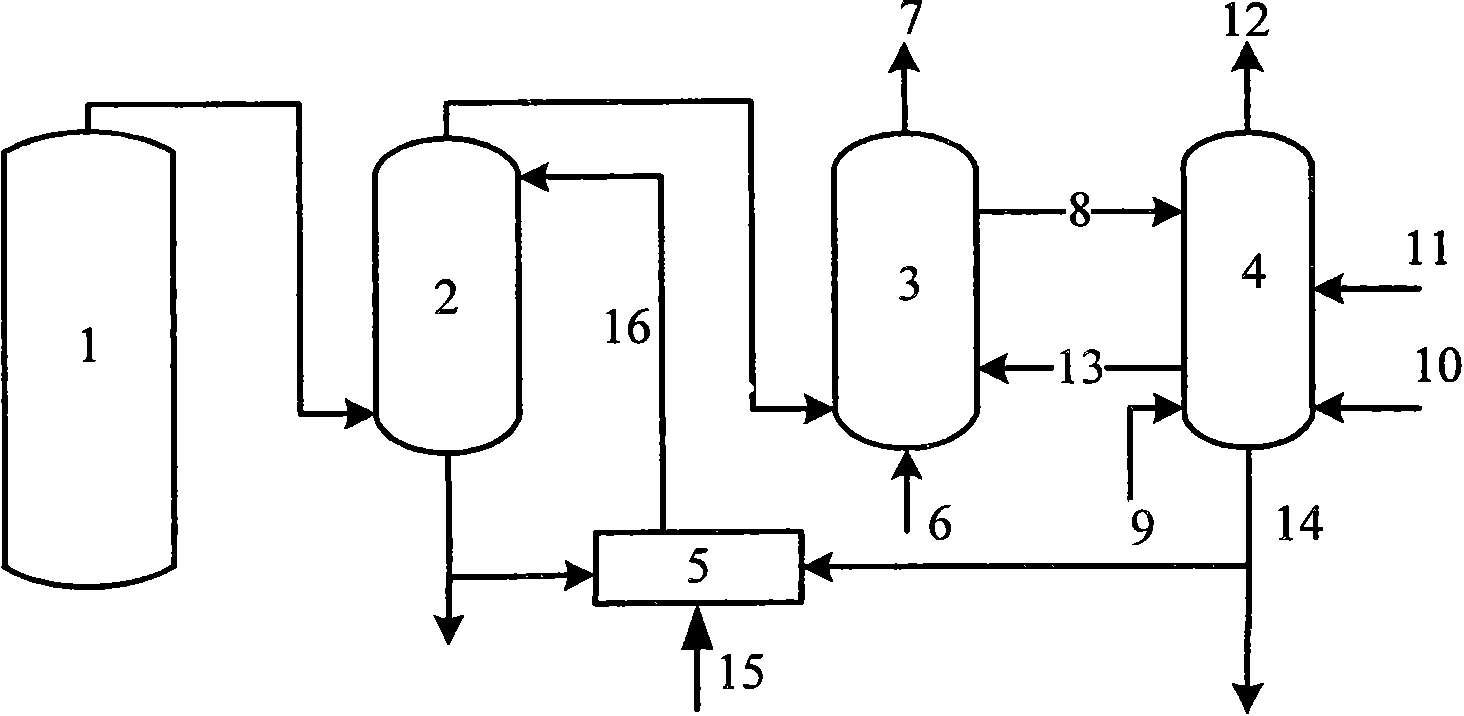

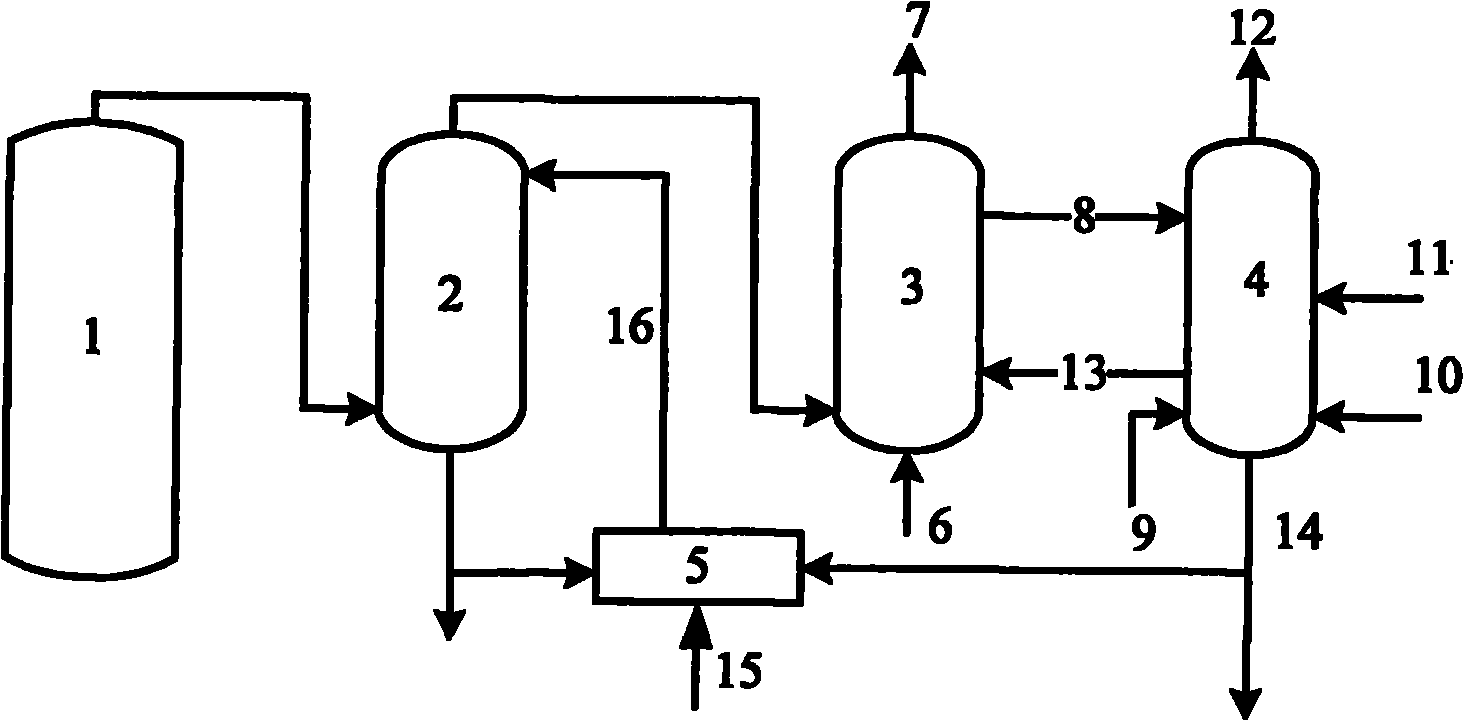

[0021] Such as figure 1 As shown, the flue gas produced by the pulverized coal furnace 1 of the power station is desulfurized by the desulfurization tower 2, and then enters the fluidized bed carbonation reactor 3, and the CO 2 CO in flue gas7 after being captured 2 The content of CaO is very low and can be directly discharged into the atmosphere. In the fluidized bed carbonation reactor 3, CaO generates solid Ca(OH) under the action of steam 6 from the steam turbine. 2 , the molar ratio of CaO13 to water vapor 6 is 1.2. Ca(OH) 2 Particles undergo carbonation reaction to capture CO 2 , the reaction temperature is 280-300°C, and the product is CaCO 3 8 and water vapor. CaCO 3 8 into the fluidized bed calciner 4 for calcination, using the heat generated by the oxygen-enriched combustion of biomass fuel 10 to make the CaCO 3 8 decomposed into CaO and CO 2 , the calcination temperature is 900-950°C, CaO13 is introduced into the fluidized bed carbonation reactor 3 to captur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com